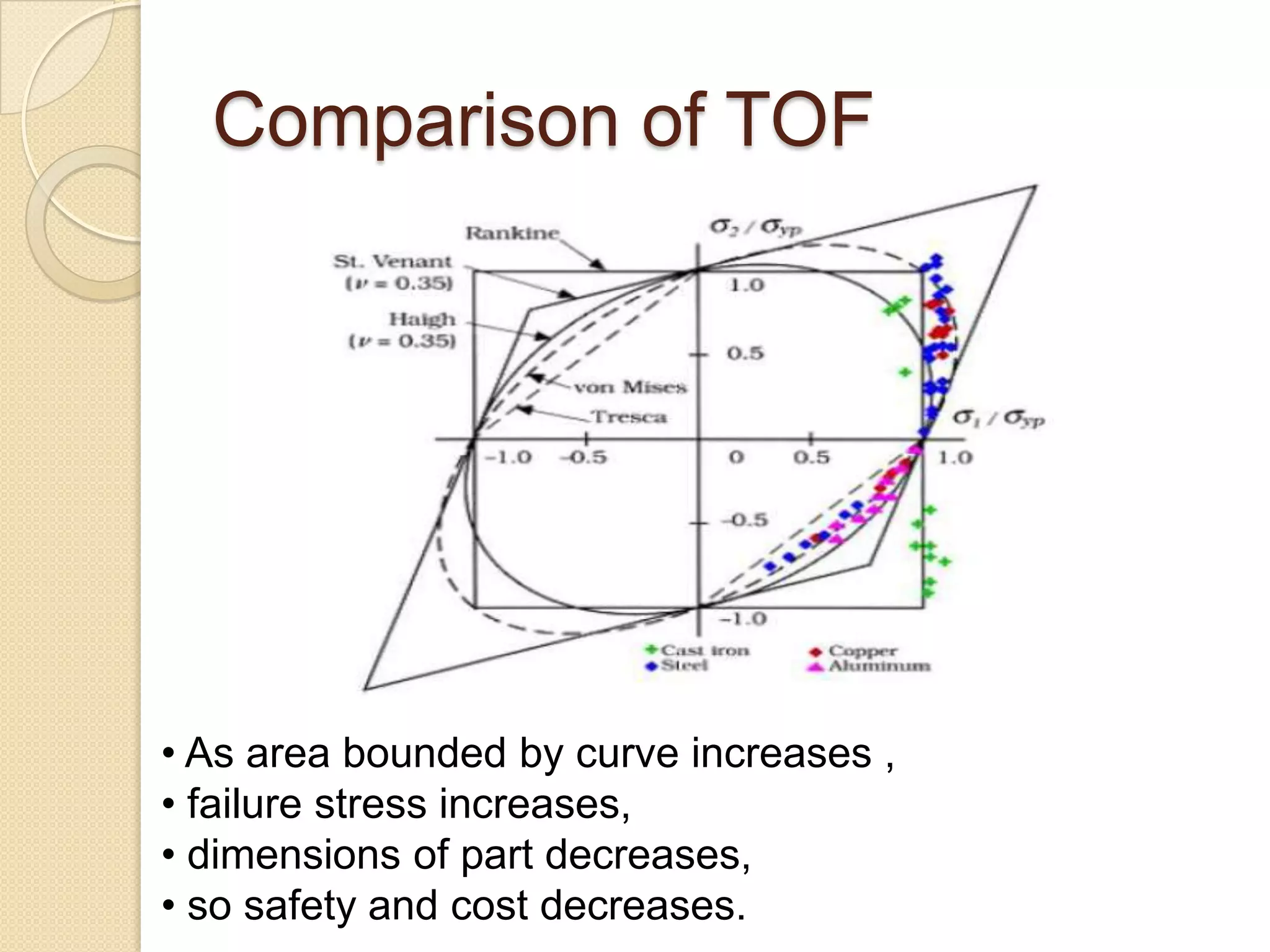

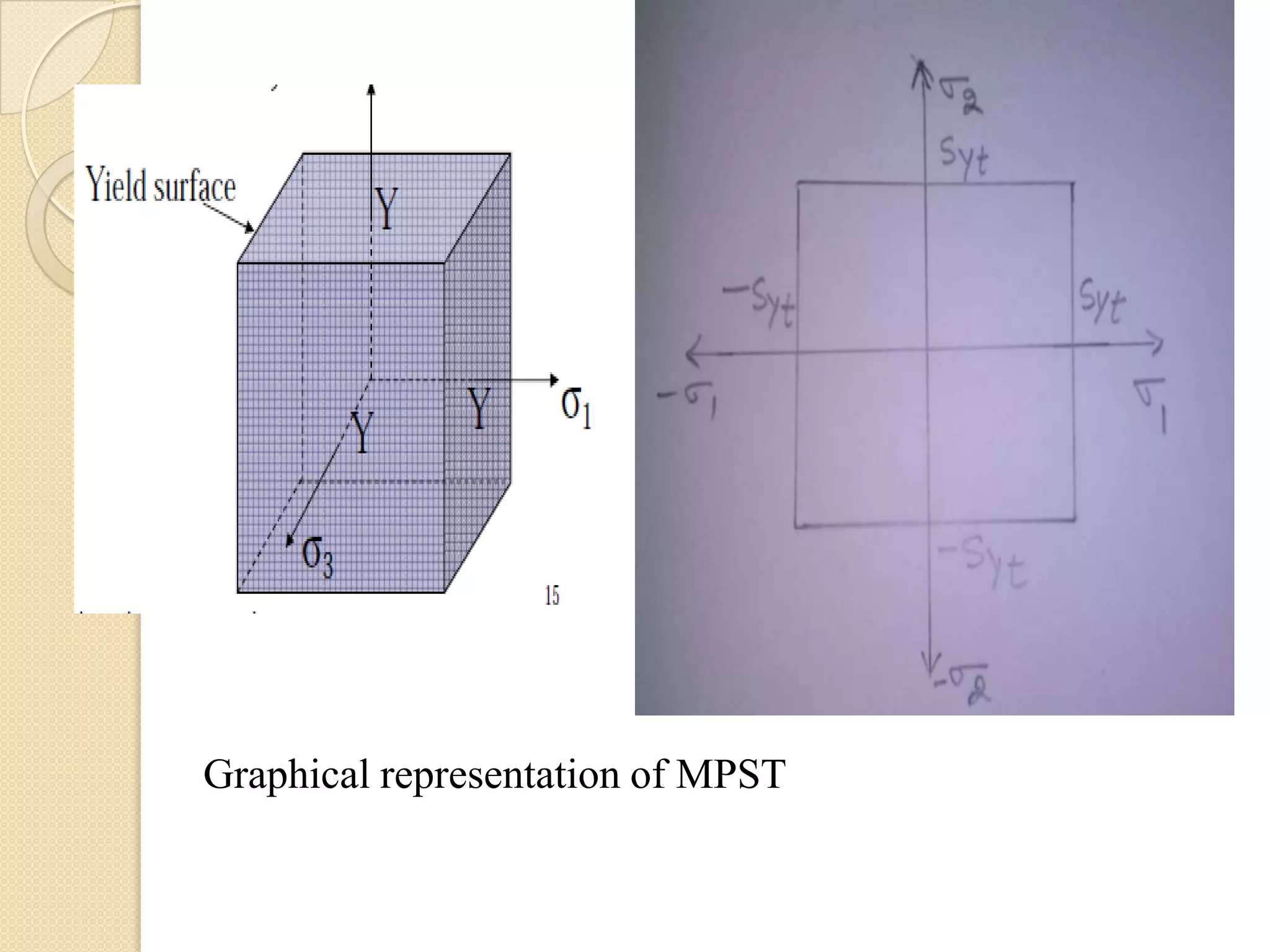

The document discusses various theories of failure that are used to determine the safe dimensions of components under combined loading conditions. It describes five theories: (1) Maximum principal stress theory, (2) Maximum principal strain theory, (3) Maximum strain energy theory, (4) Maximum distortion energy theory, and (5) Maximum shear stress theory. The maximum distortion energy theory provides the safest design for ductile materials as it results in the largest allowable stresses before failure compared to the other theories. The document also compares the various theories and discusses when each is best applied depending on the material type and stress conditions.

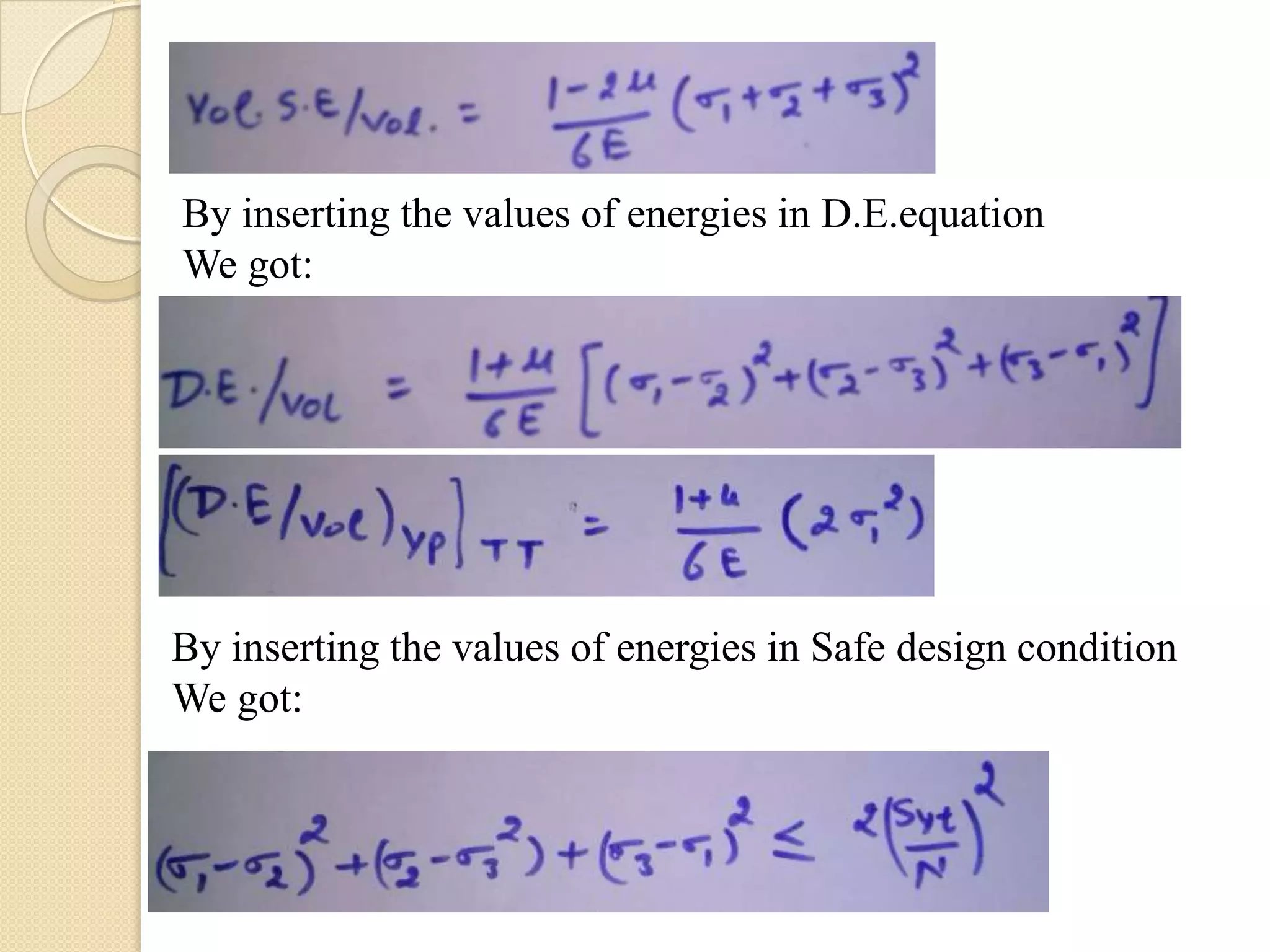

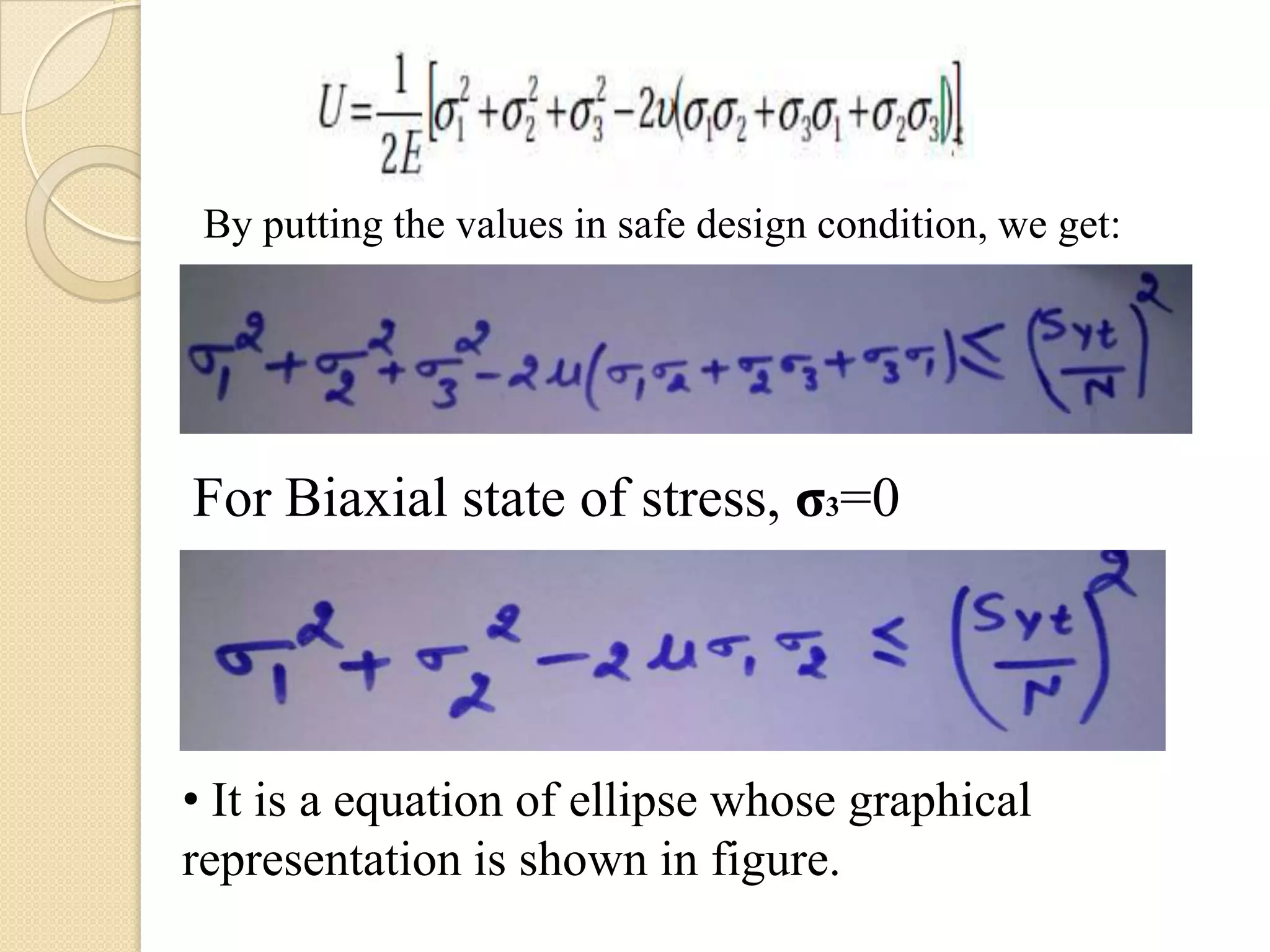

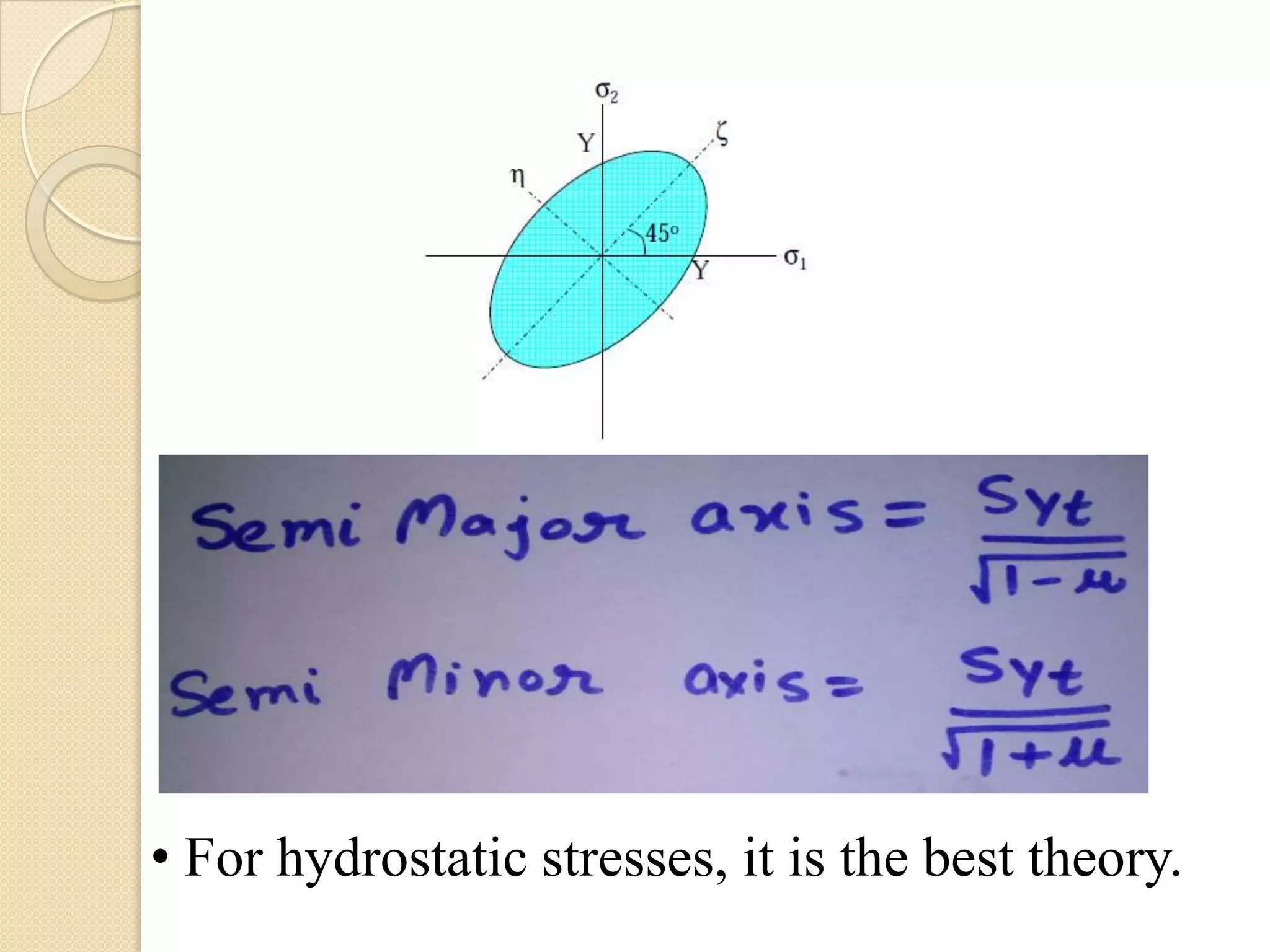

![Maximum strain energy theory:

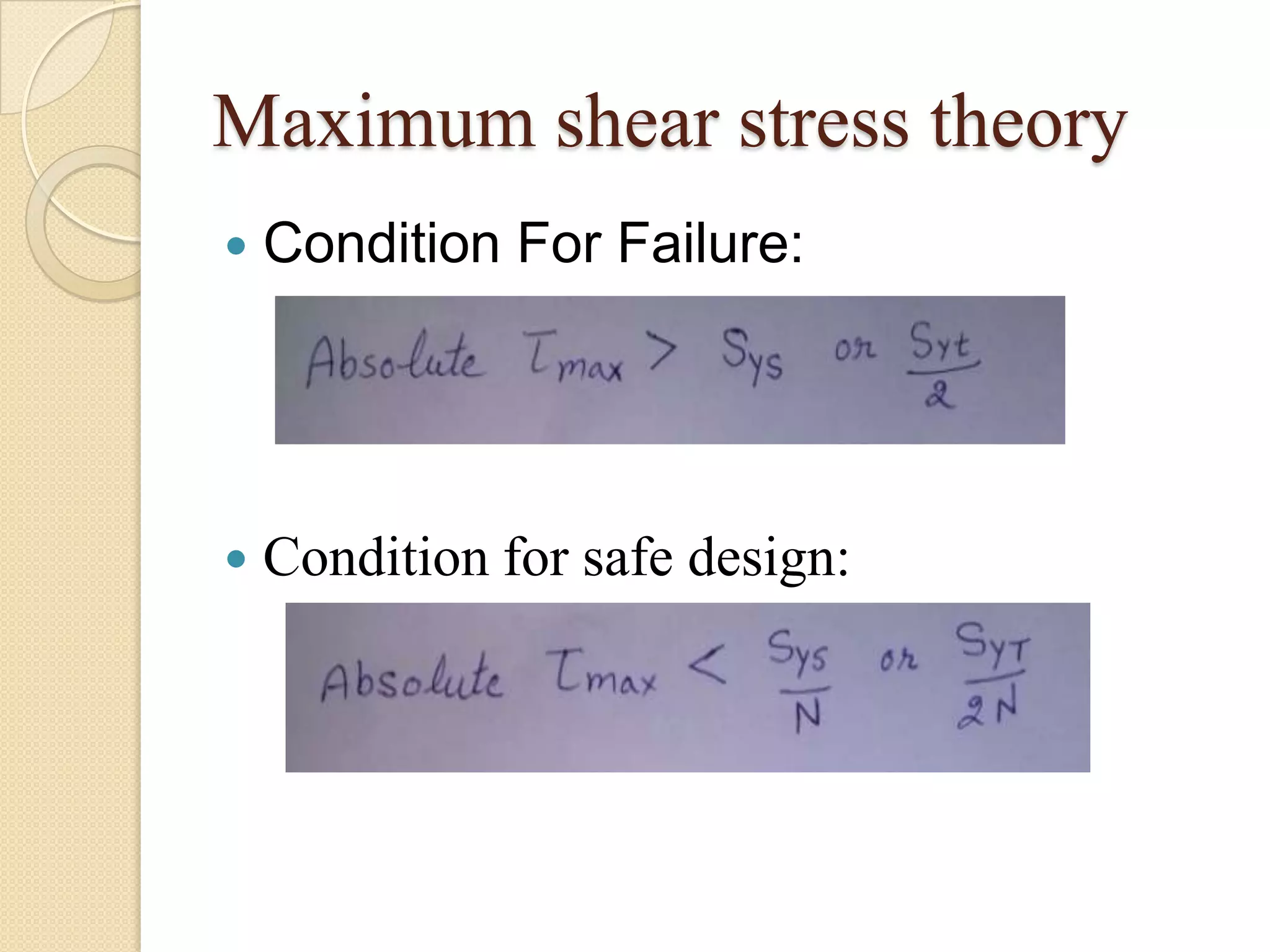

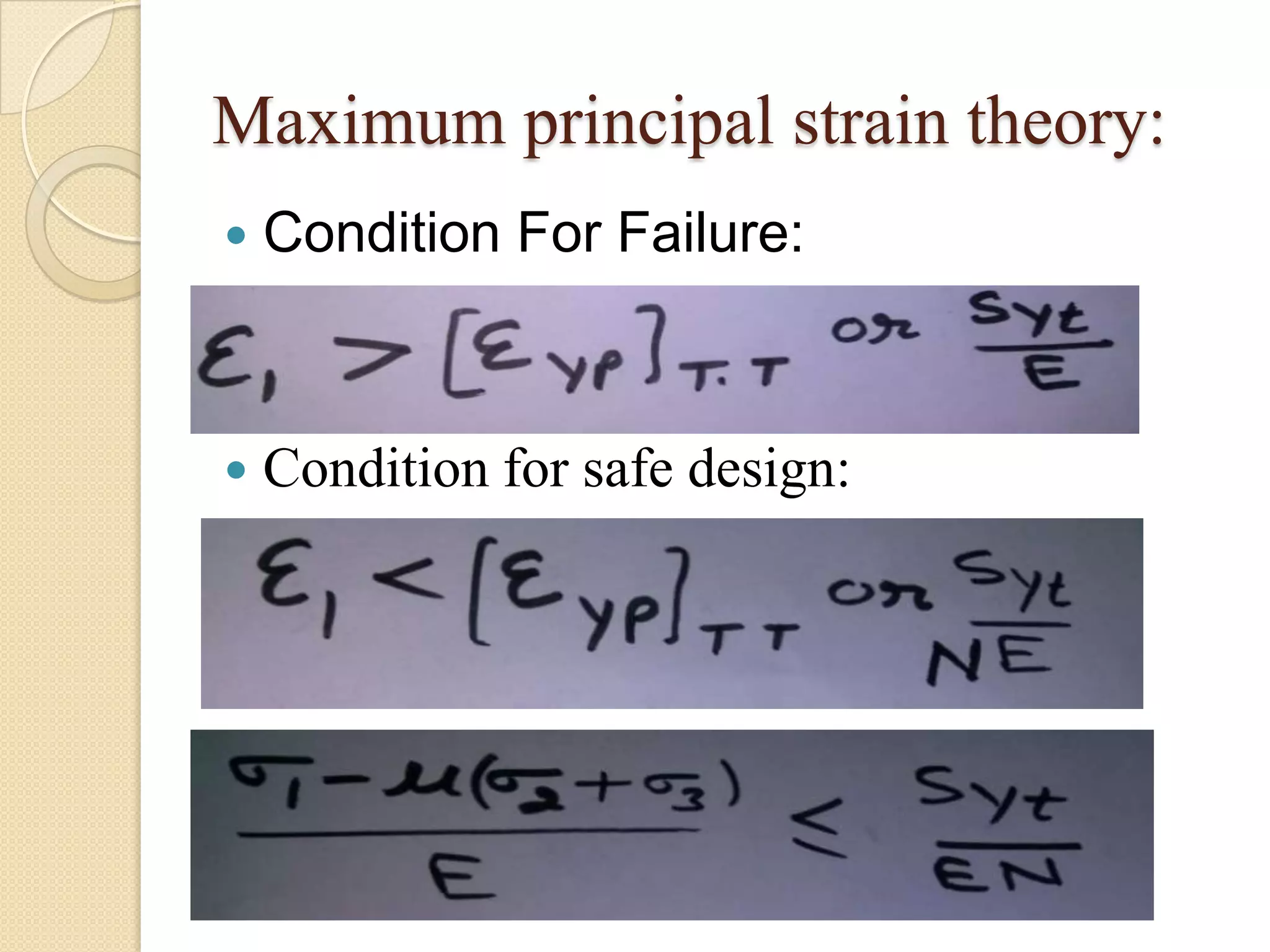

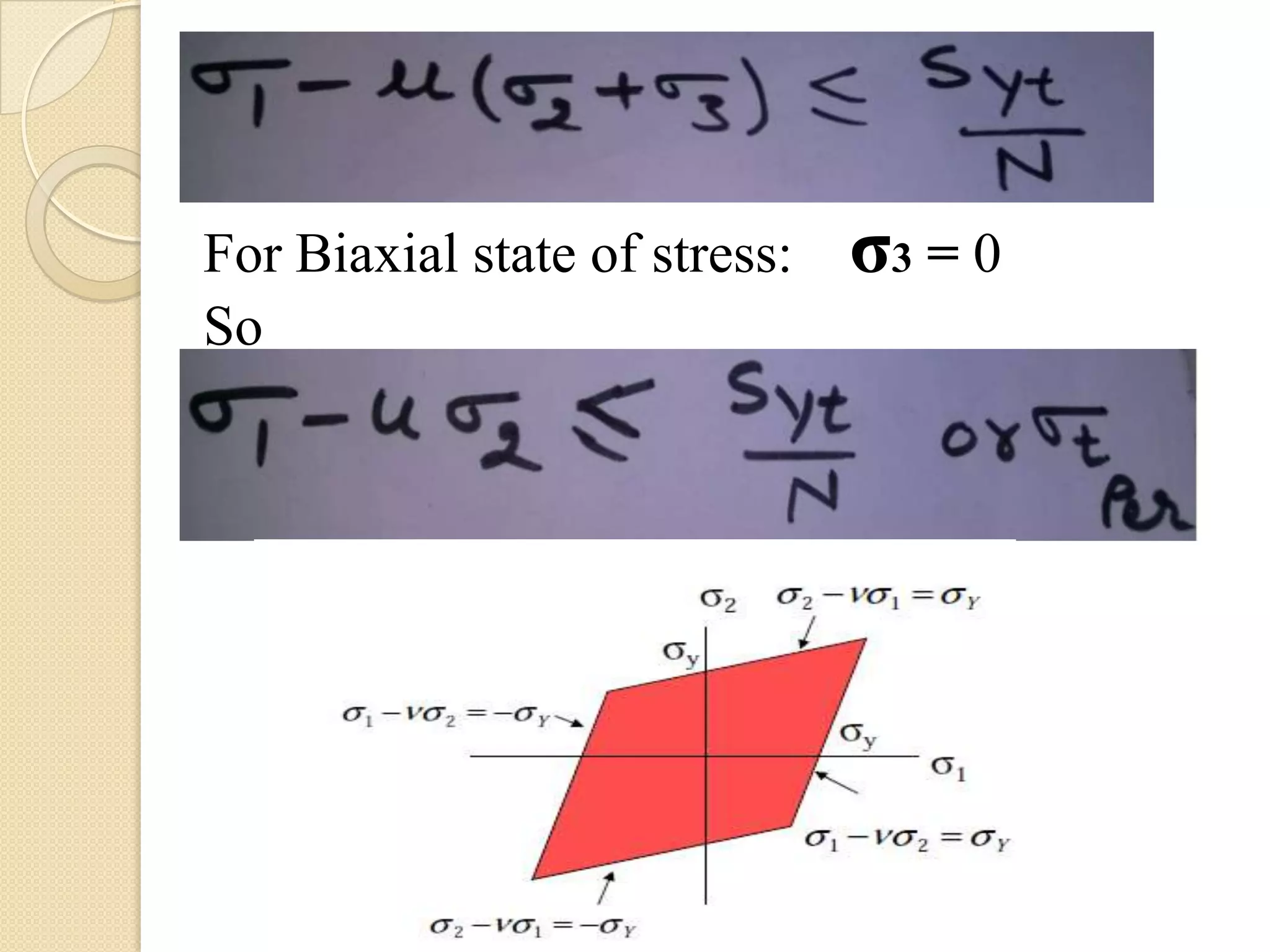

Condition For Failure:

Total strain energy/vol > [(S.E/vol)yp]TT

Condition for safe design:

Total strain energy/vol < [(S.E/vol)yp]TT

Under triaxial loading condition:](https://image.slidesharecdn.com/mechanicalbehaviorofmaterials-140430093834-phpapp01/75/theories-of-failure-13-2048.jpg)

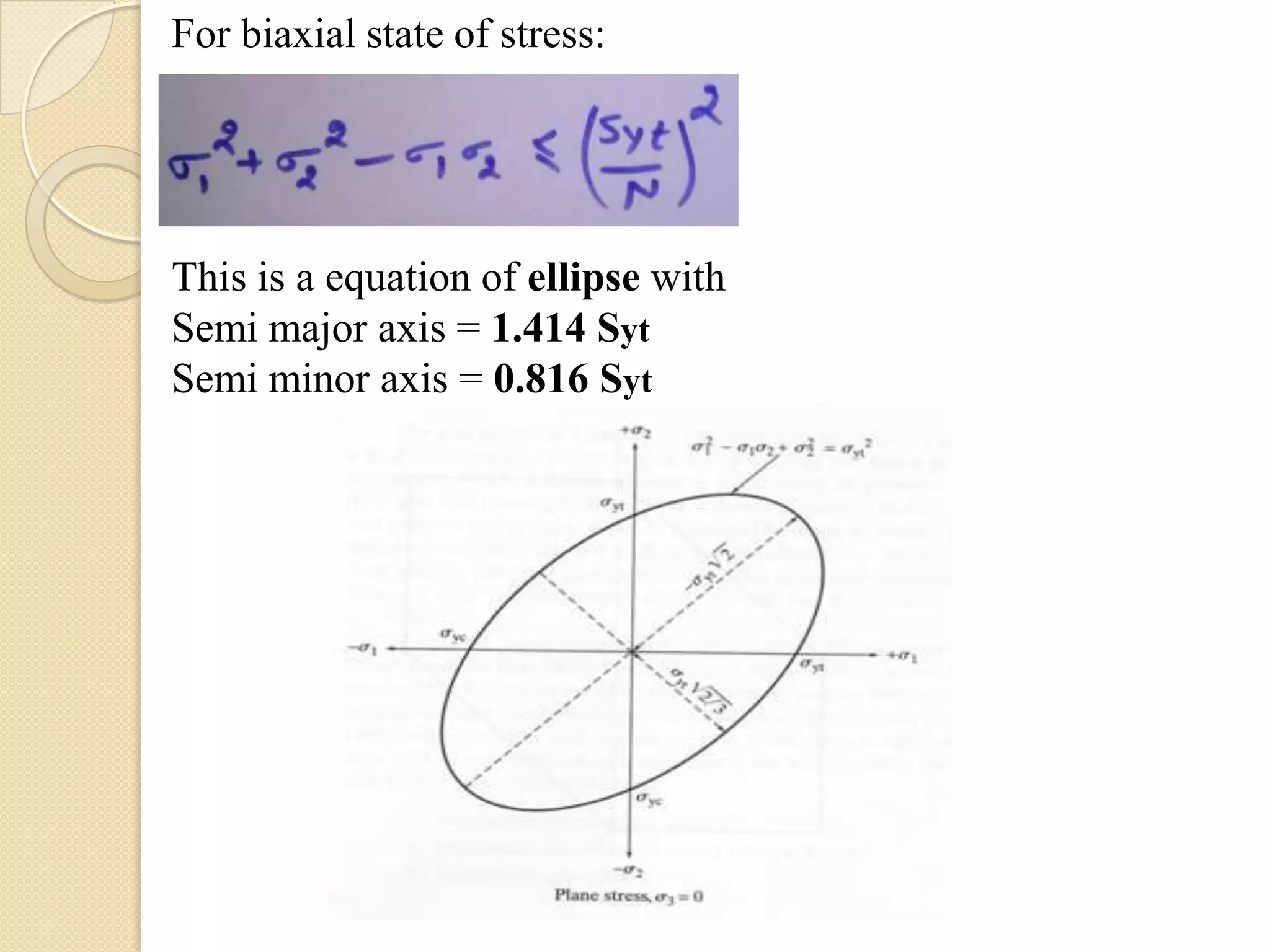

![Maximum Distortion energy theory:

Condition For Failure:

Max. D.E. / volume > [(D.E./vol.)yp]TT

Condition for safe design:

Max. D.E. / volume < [(D.E./vol.)yp]TT

Max. D.E. / vol = Total S.E. /vol – volumetric S.E. / vol](https://image.slidesharecdn.com/mechanicalbehaviorofmaterials-140430093834-phpapp01/75/theories-of-failure-16-2048.jpg)