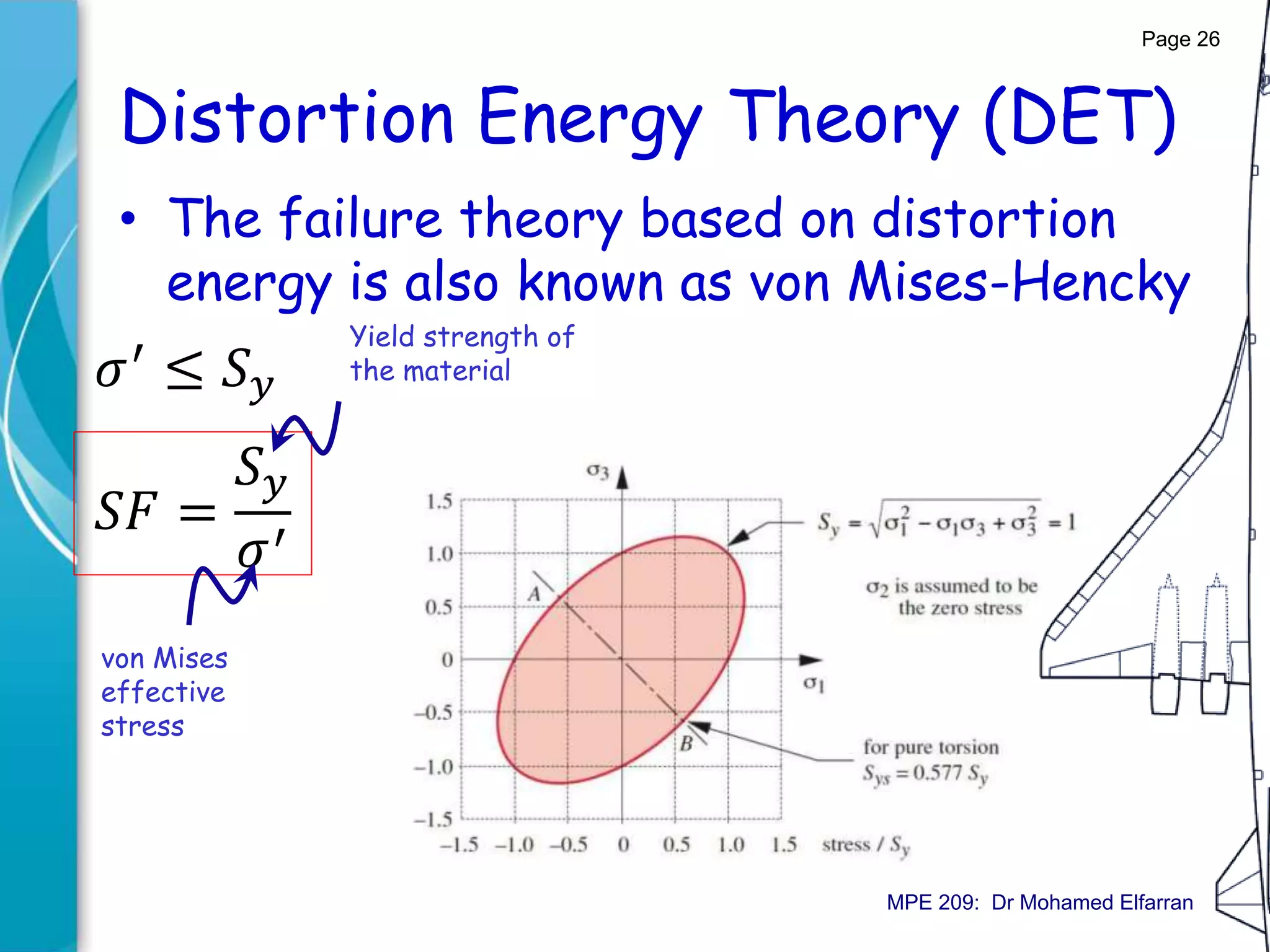

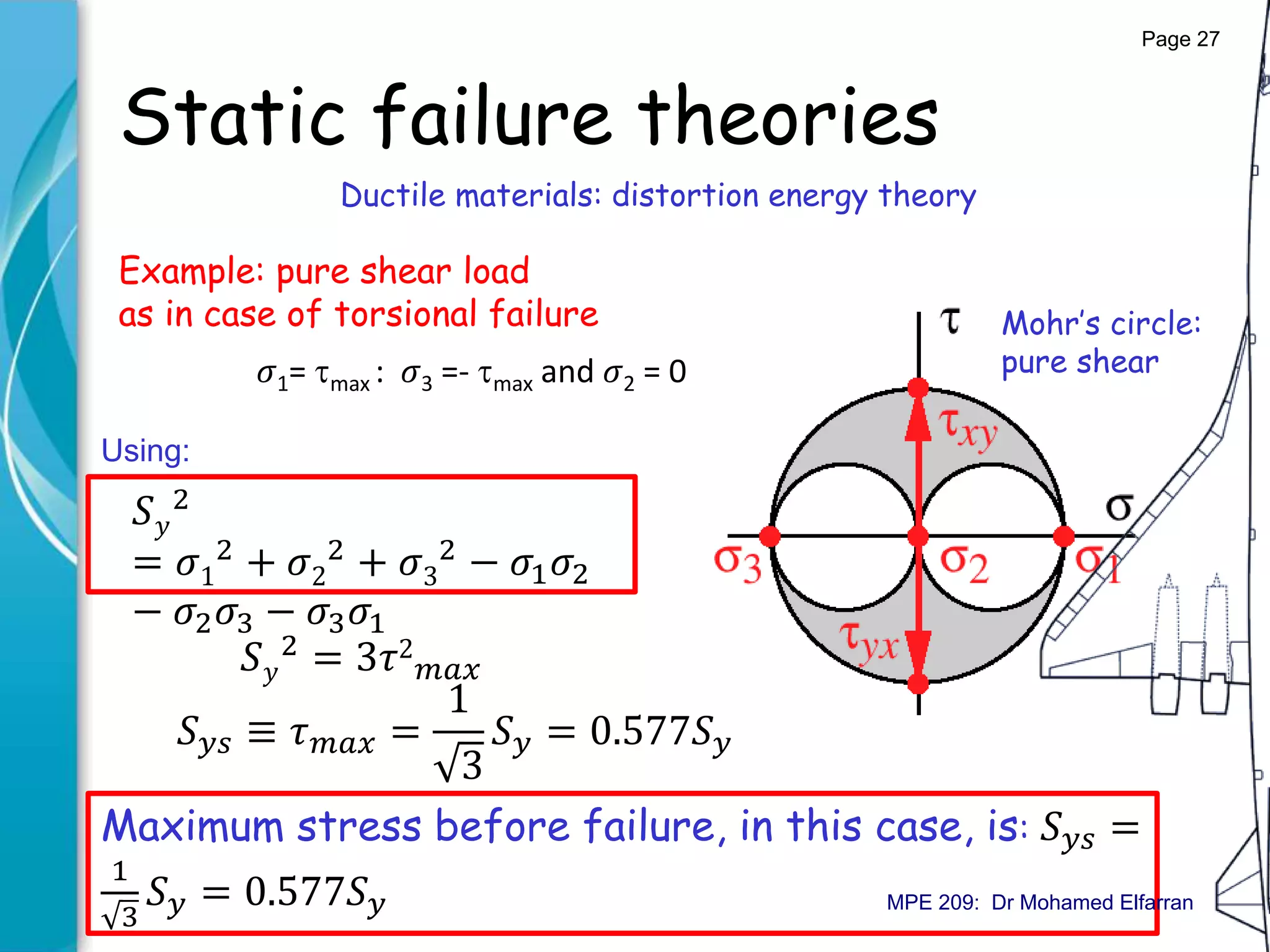

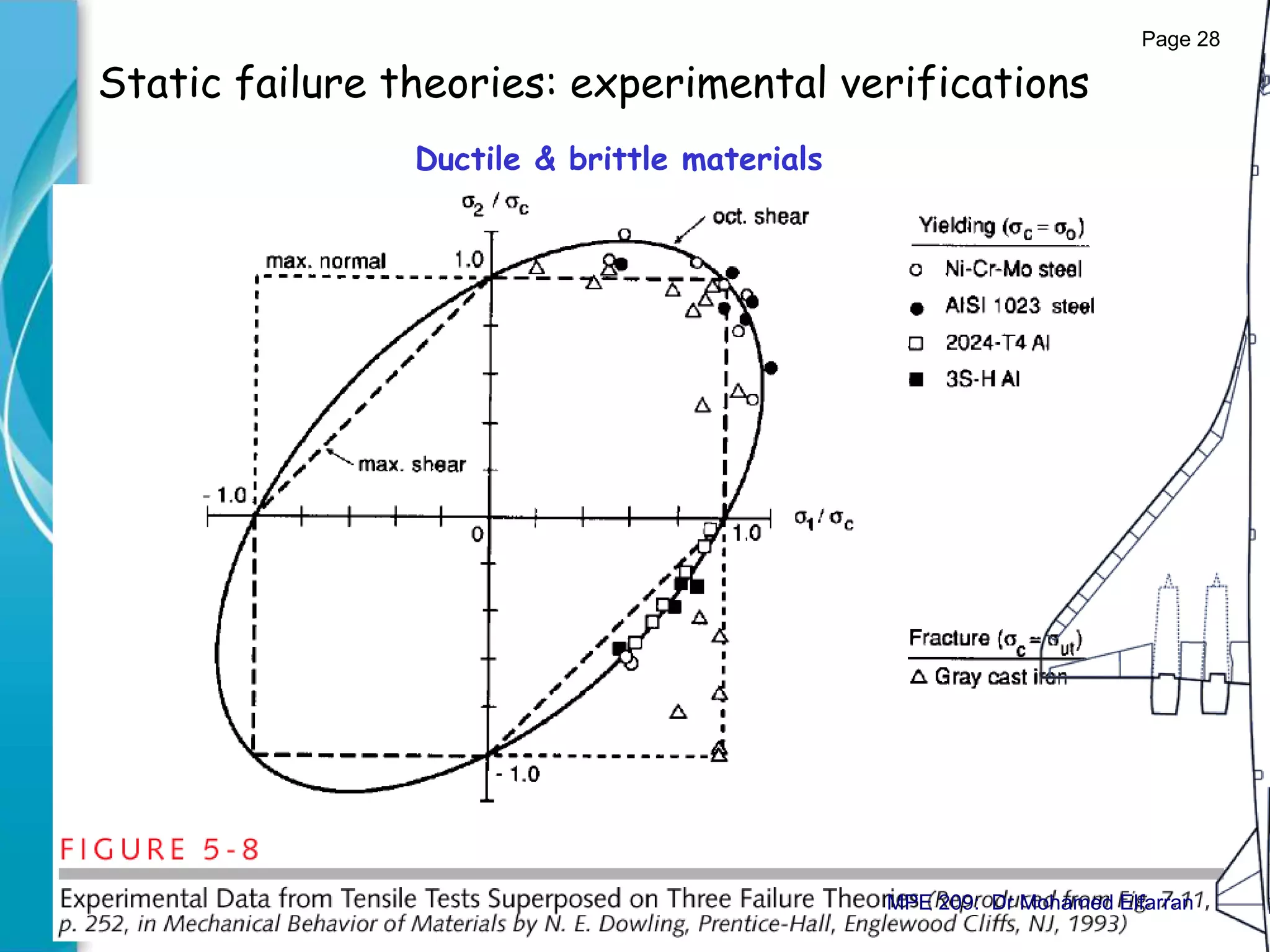

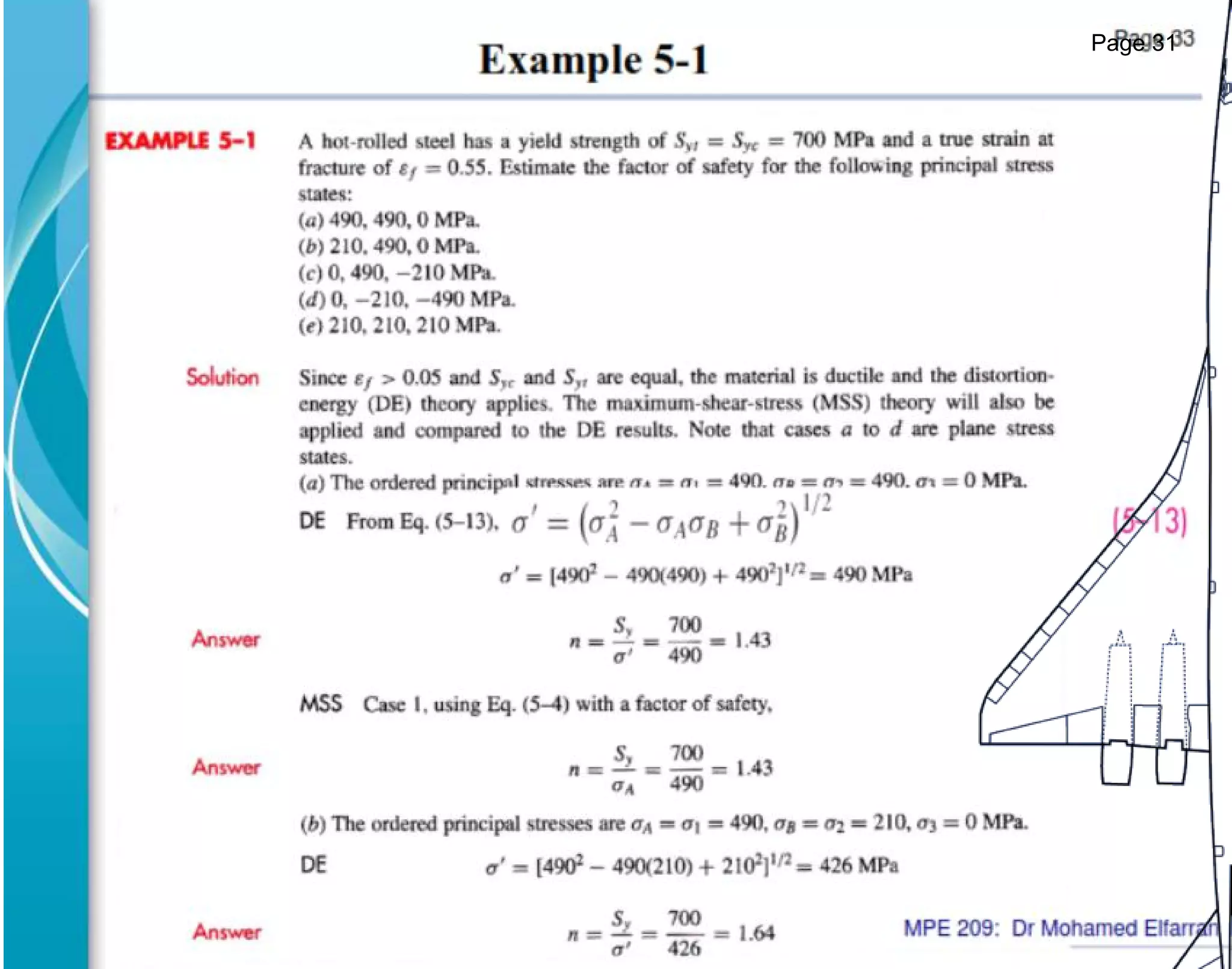

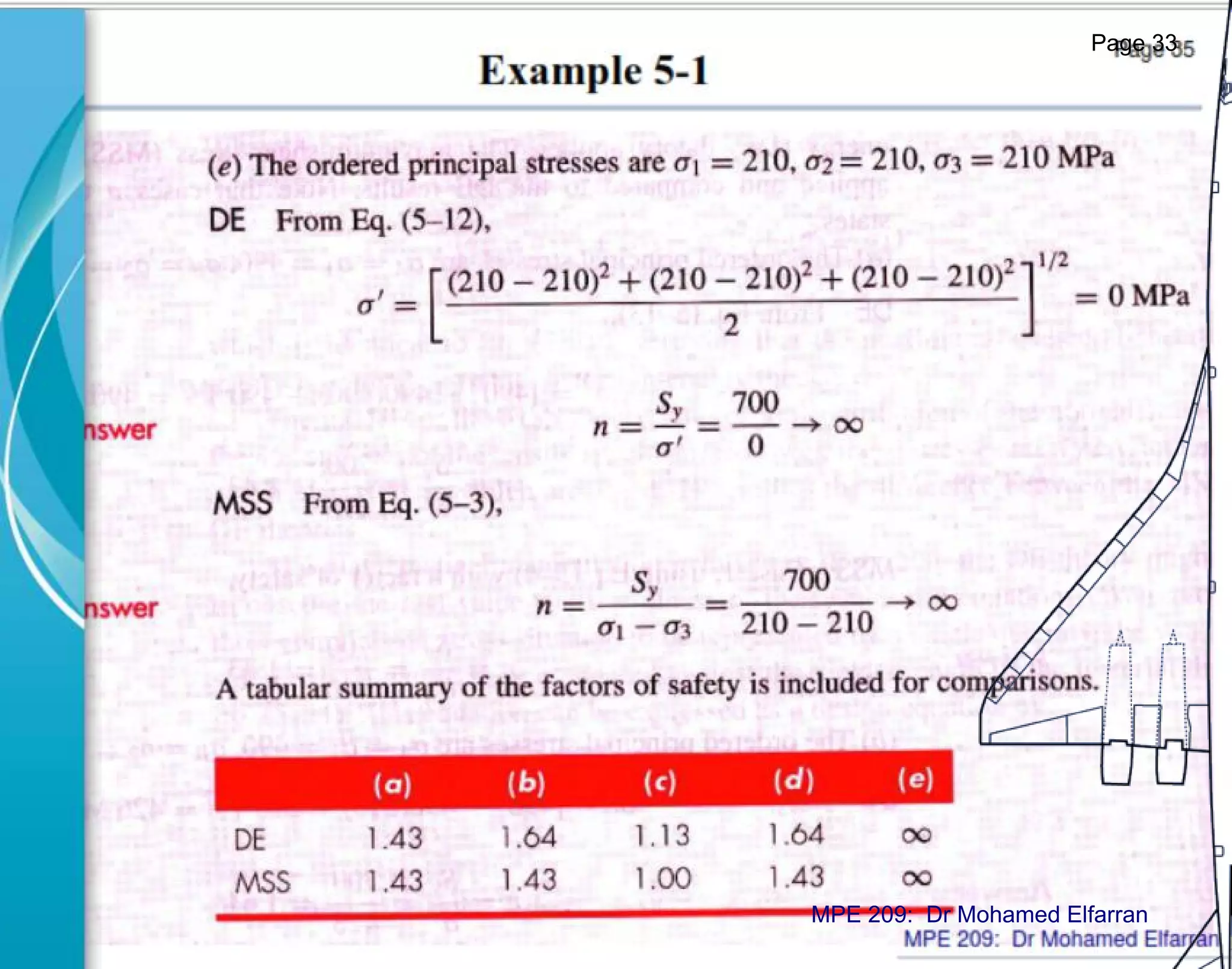

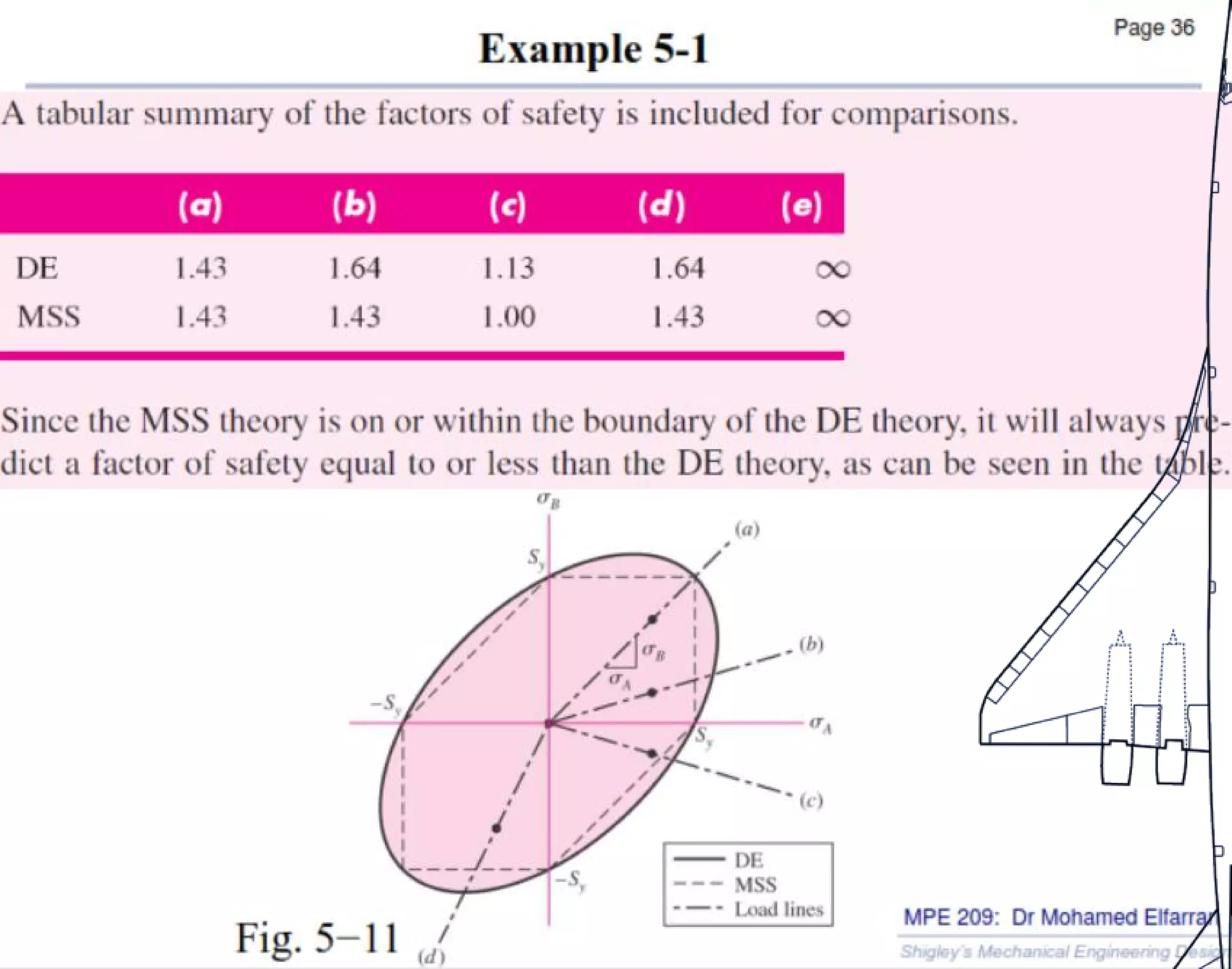

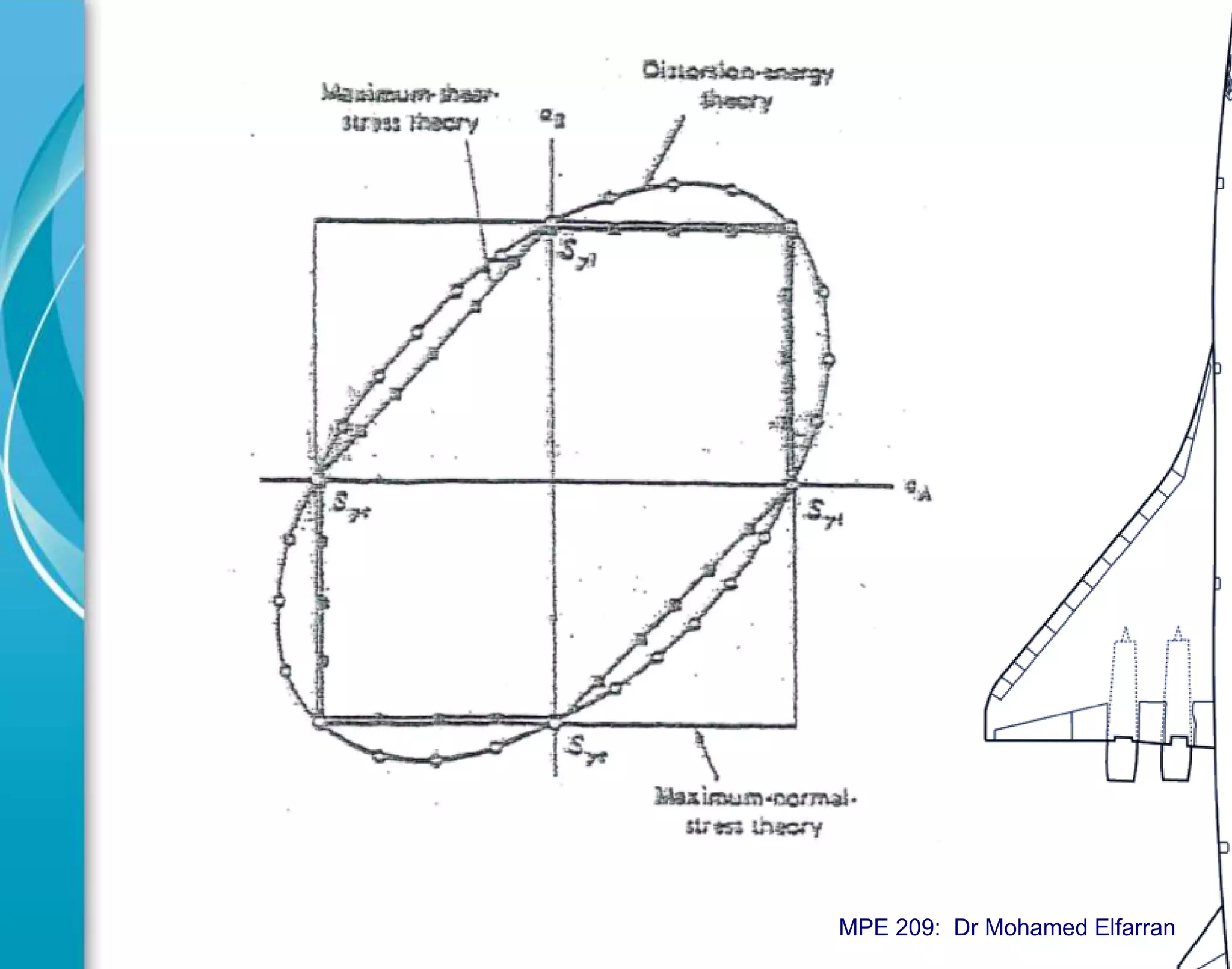

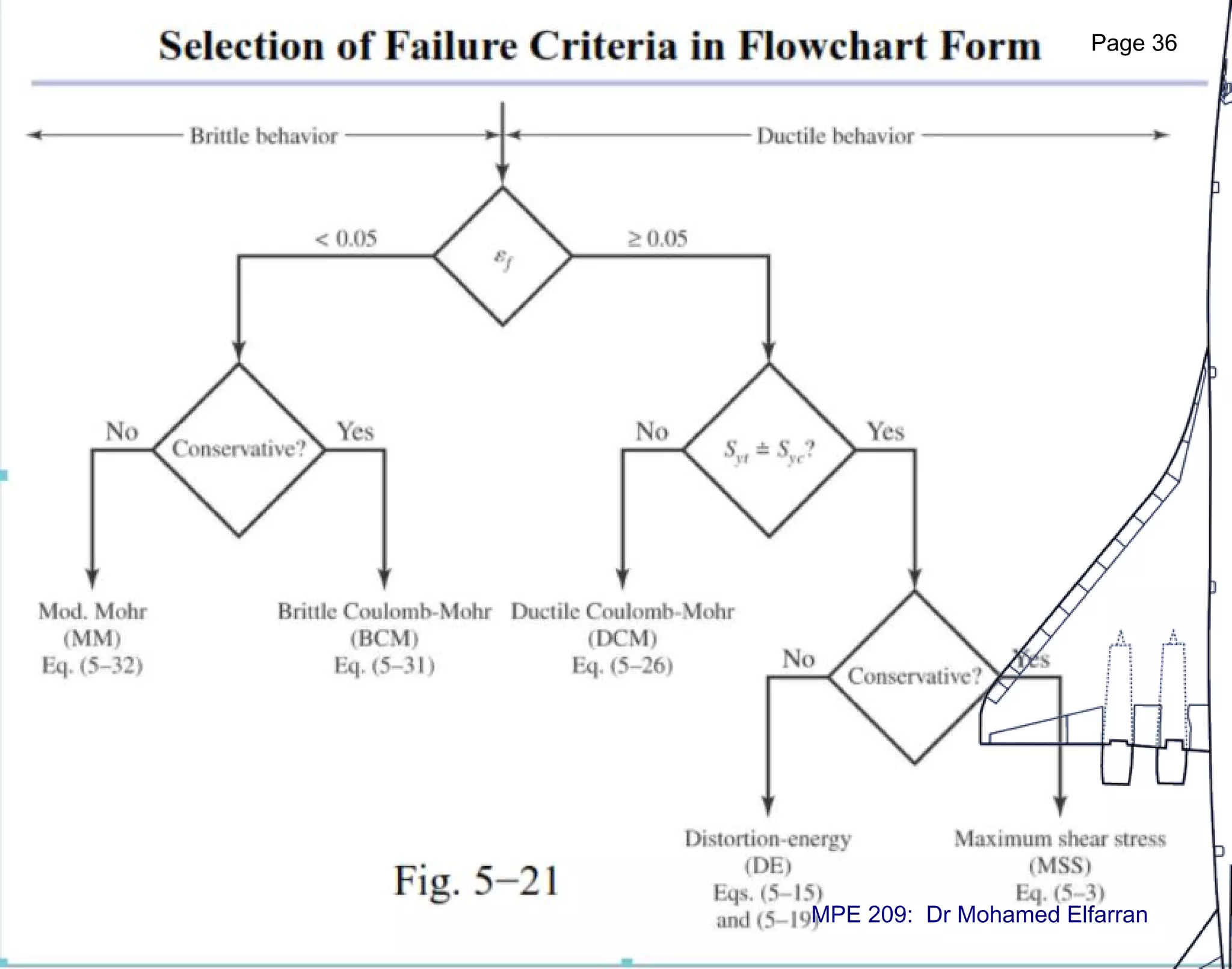

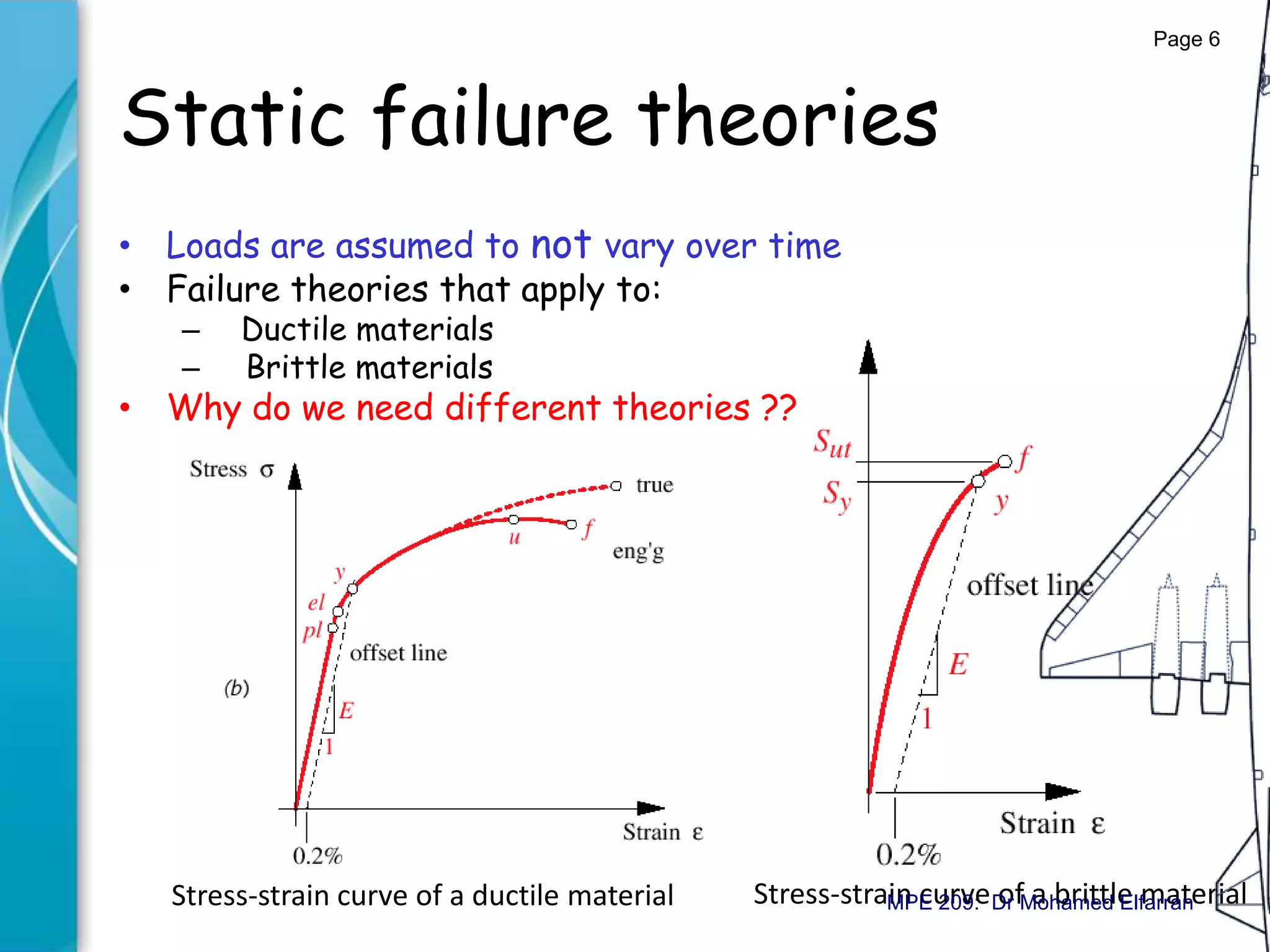

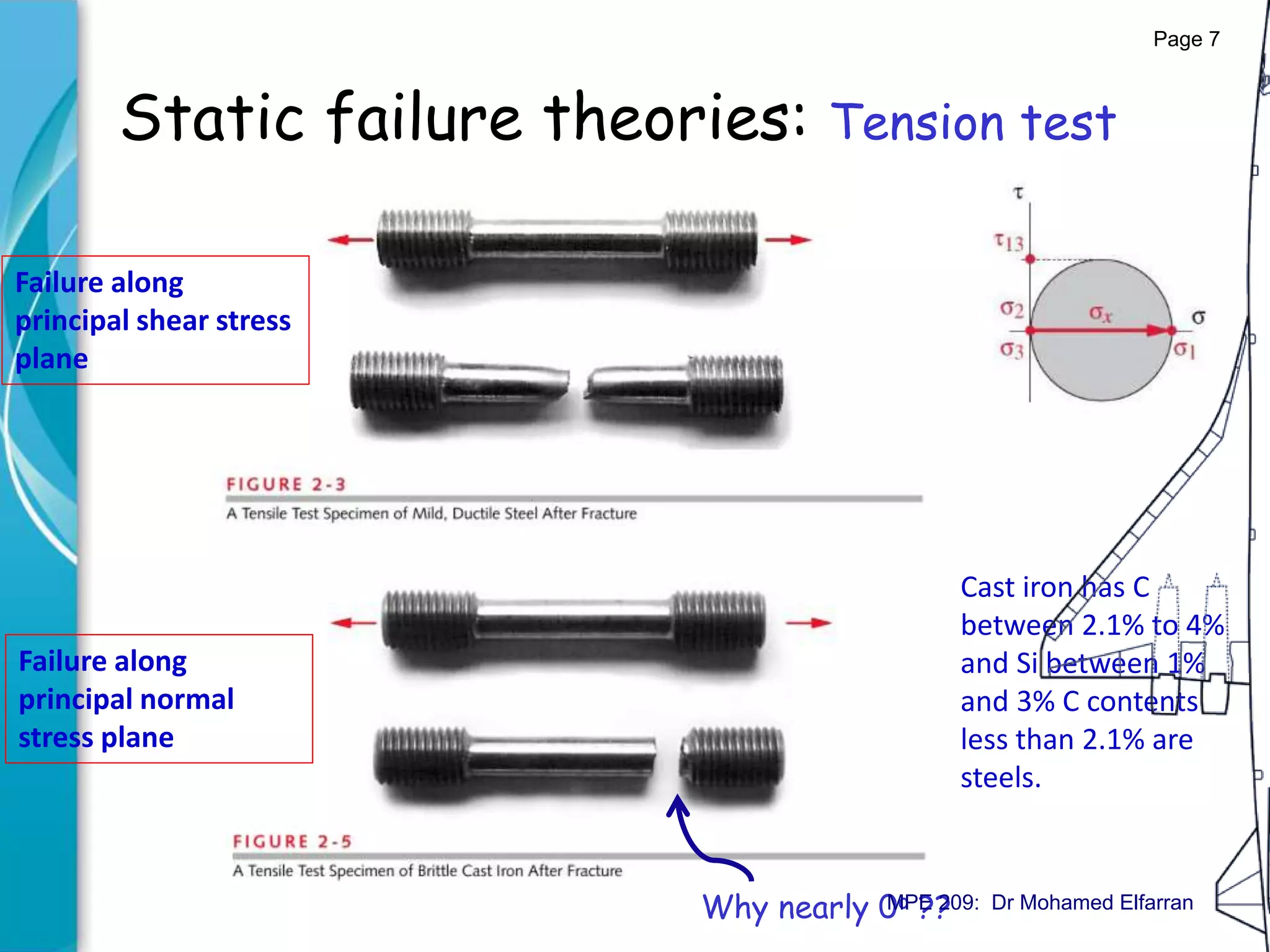

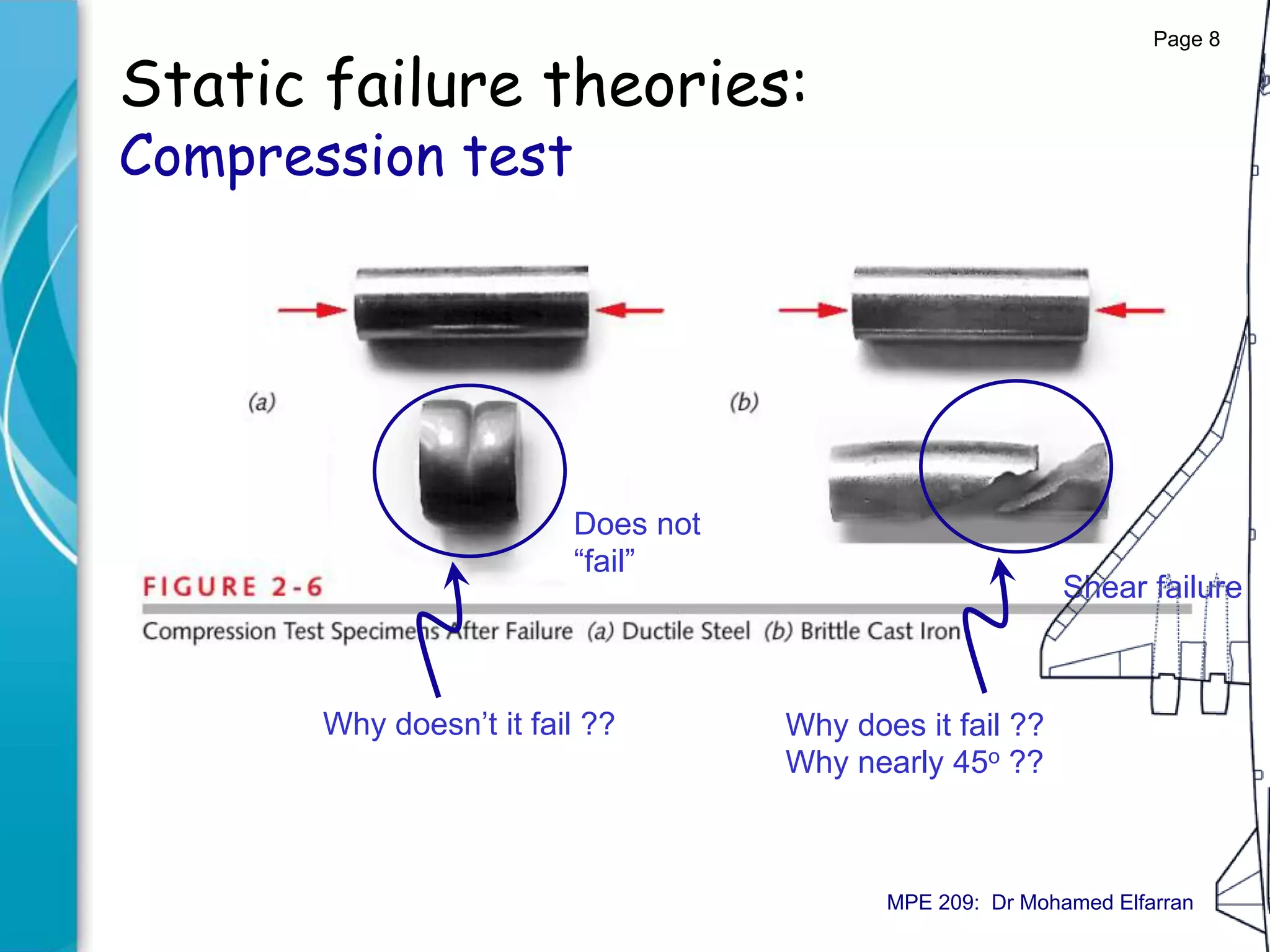

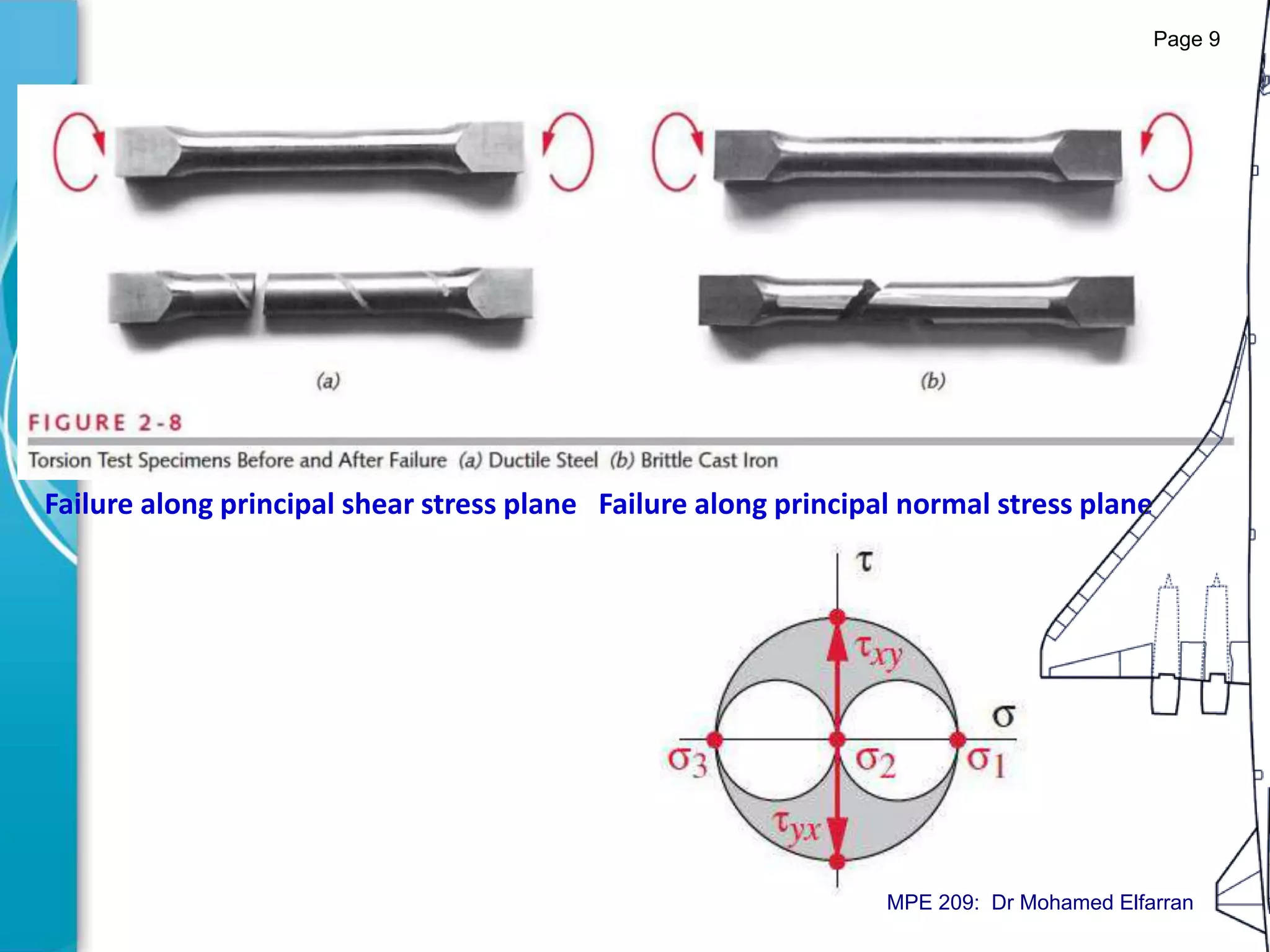

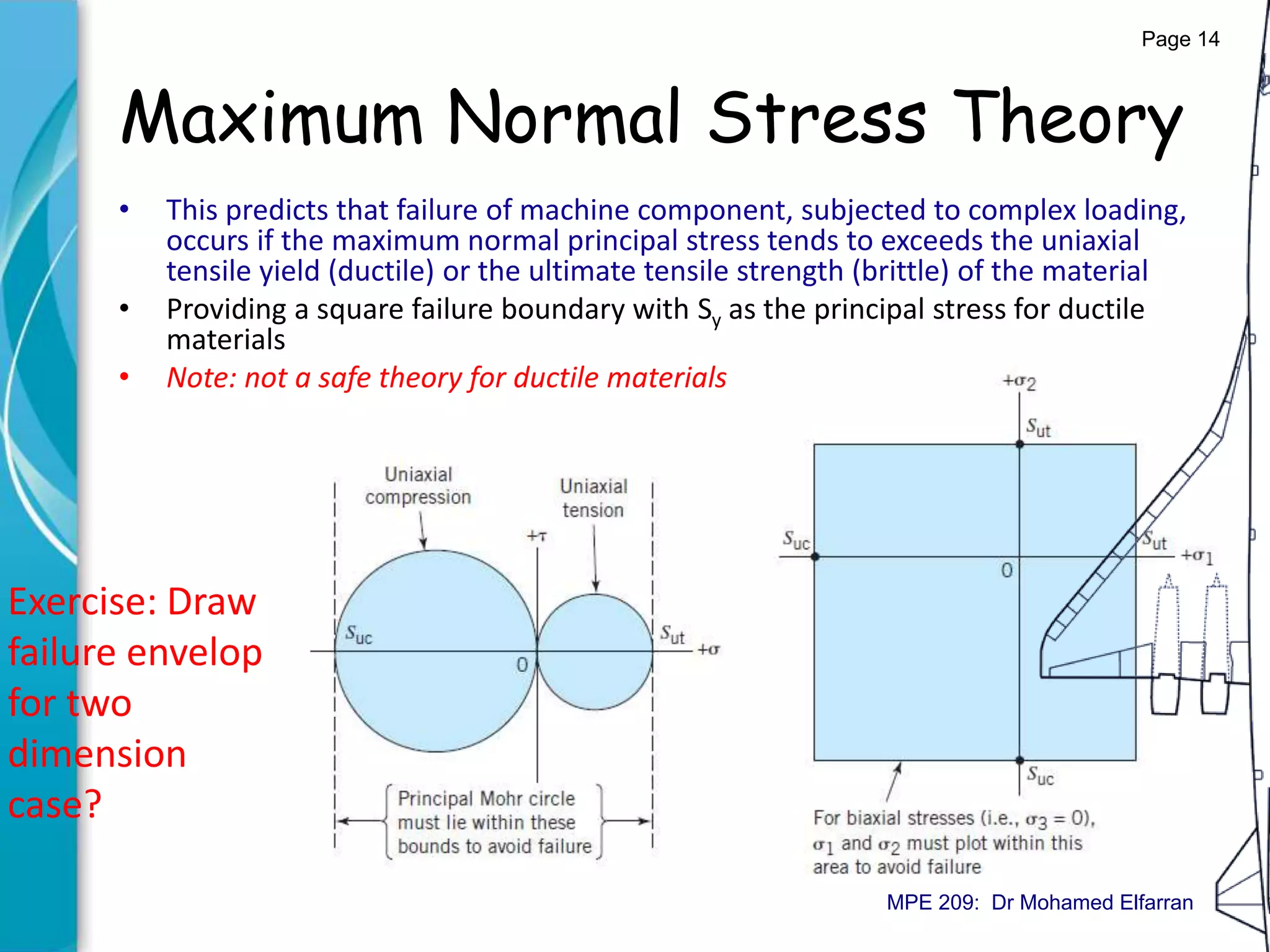

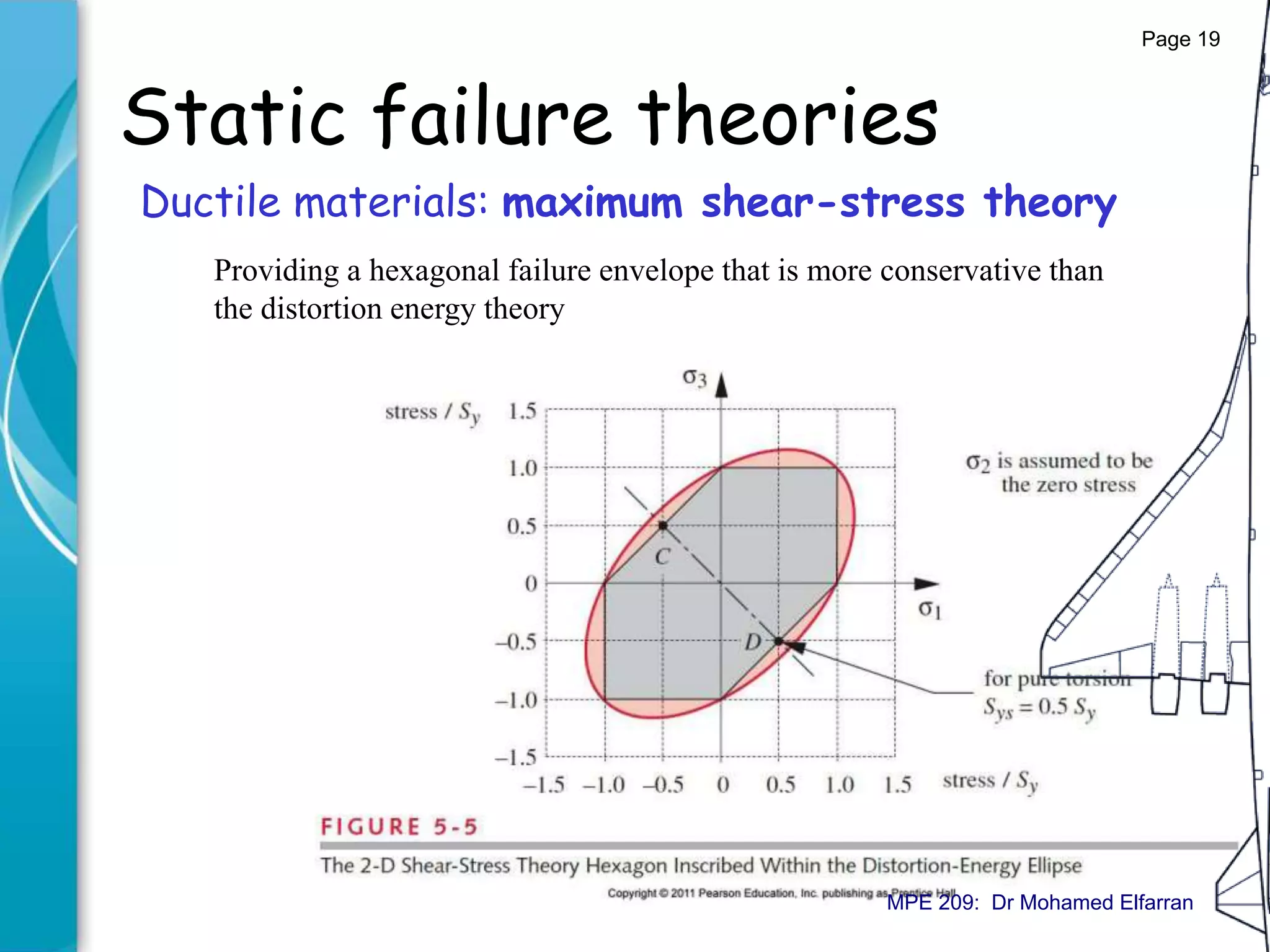

The document discusses static failure theories in engineering, explaining why machine parts fail due to stress exceeding material strength. It differentiates between elastic and fracture failures and outlines various failure theories applicable to ductile and brittle materials. Key concepts include the importance of shear and tensile strengths, and how different loading conditions affect failure mechanisms.

![Static failure theories

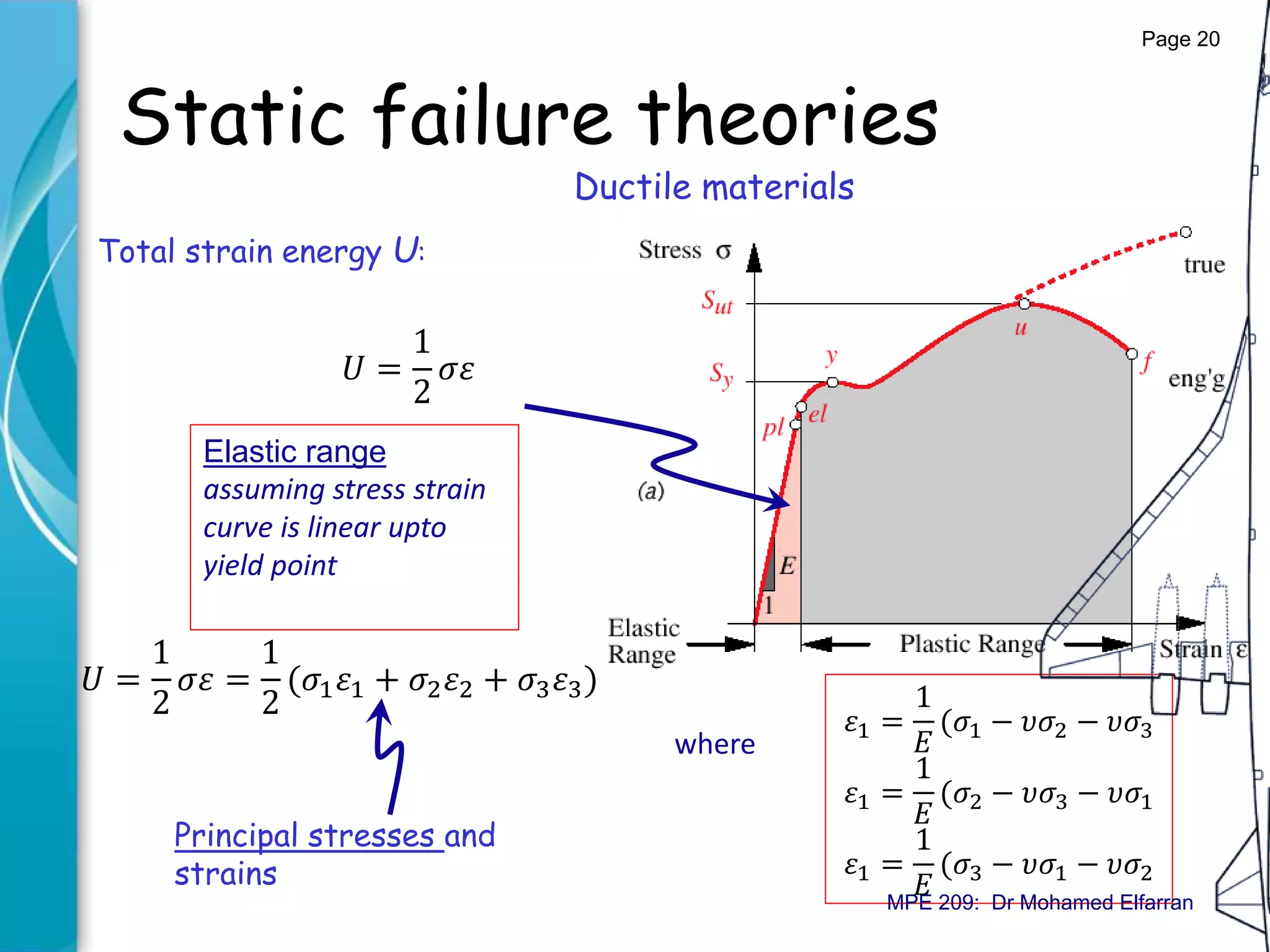

Ductile materials: total strain energy

Using previous expressions, total energy is:

𝑈 =

1

2

𝜎𝜀 =

1

2𝐸

[𝜎1

2

+ 𝜎2

2

+ 𝜎3

2

− 2𝜐(𝜎1 𝜎2 + 𝜎2 𝜎3 + 𝜎3 𝜎1)

which can be expressed as 𝑈 = 𝑈ℎ + 𝑈 𝑑

Hydrostatic energy Deformation energy

𝑈ℎ =

3

2

(1 − 2𝜐)

𝐸

𝜎ℎ

2

𝜎ℎ =

𝜎1 + 𝜎2 + 𝜎3

3

Obtained by setting:

𝑈ℎ = 𝑈(𝜎1 = 𝜎2 = 𝜎3 = 𝜎ℎ)

𝑈 𝑑 =

1 + 𝜐

3𝐸

[𝜎1

2 + 𝜎2

2 + 𝜎3

2

−(𝜎1 𝜎2 + 𝜎2 𝜎3 + 𝜎3 𝜎1)]

Obtained by setting:

𝑈 𝑑 = 𝑈 − 𝑈ℎ

Page 21

MPE 209: Dr Mohamed Elfarran](https://image.slidesharecdn.com/mpe209lec41-201116171650/75/MEP-209-Design-of-Machine-elements-LEC-4-21-2048.jpg)

![Static failure theories

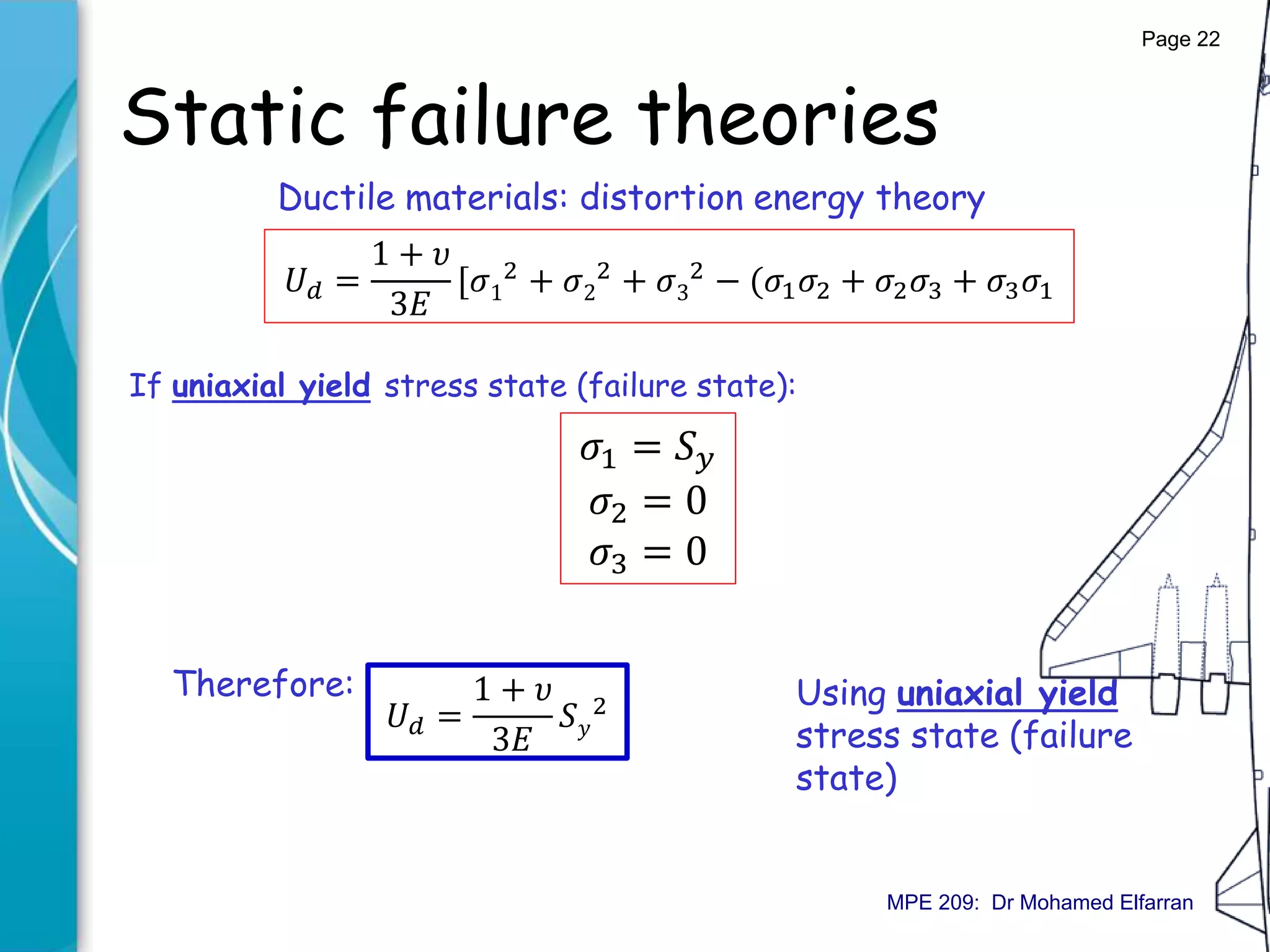

Ductile materials: distortion energy theory

𝑈 𝑑 =

1 + 𝜐

3𝐸

[𝜎1

2 + 𝜎2

2 + 𝜎3

2 − 𝜎1 𝜎2 + 𝜎2 𝜎3 + 𝜎3 𝜎1 ]

For any other state of stresses:

Failure criterion is obtained by setting:

1 + 𝜐

3𝐸

[𝜎1

2

+ 𝜎2

2

+ 𝜎3

2

− (𝜎1 𝜎2 + 𝜎2 𝜎3 + 𝜎3 𝜎1] ≤

1 + 𝜐

3𝐸

𝑆 𝑦

2

Distortion energy:

uniaxial stress at

yield

Distortion energy:

any other state of

stresses

𝜎1

2 + 𝜎2

2 + 𝜎3

2 − 𝜎1 𝜎2 − 𝜎2 𝜎3 − 𝜎3 𝜎1 ≤ 𝑆 𝑦

2

Page 23

MPE 209: Dr Mohamed Elfarran](https://image.slidesharecdn.com/mpe209lec41-201116171650/75/MEP-209-Design-of-Machine-elements-LEC-4-23-2048.jpg)

![Static failure theories

Ductile materials: distortion energy theory

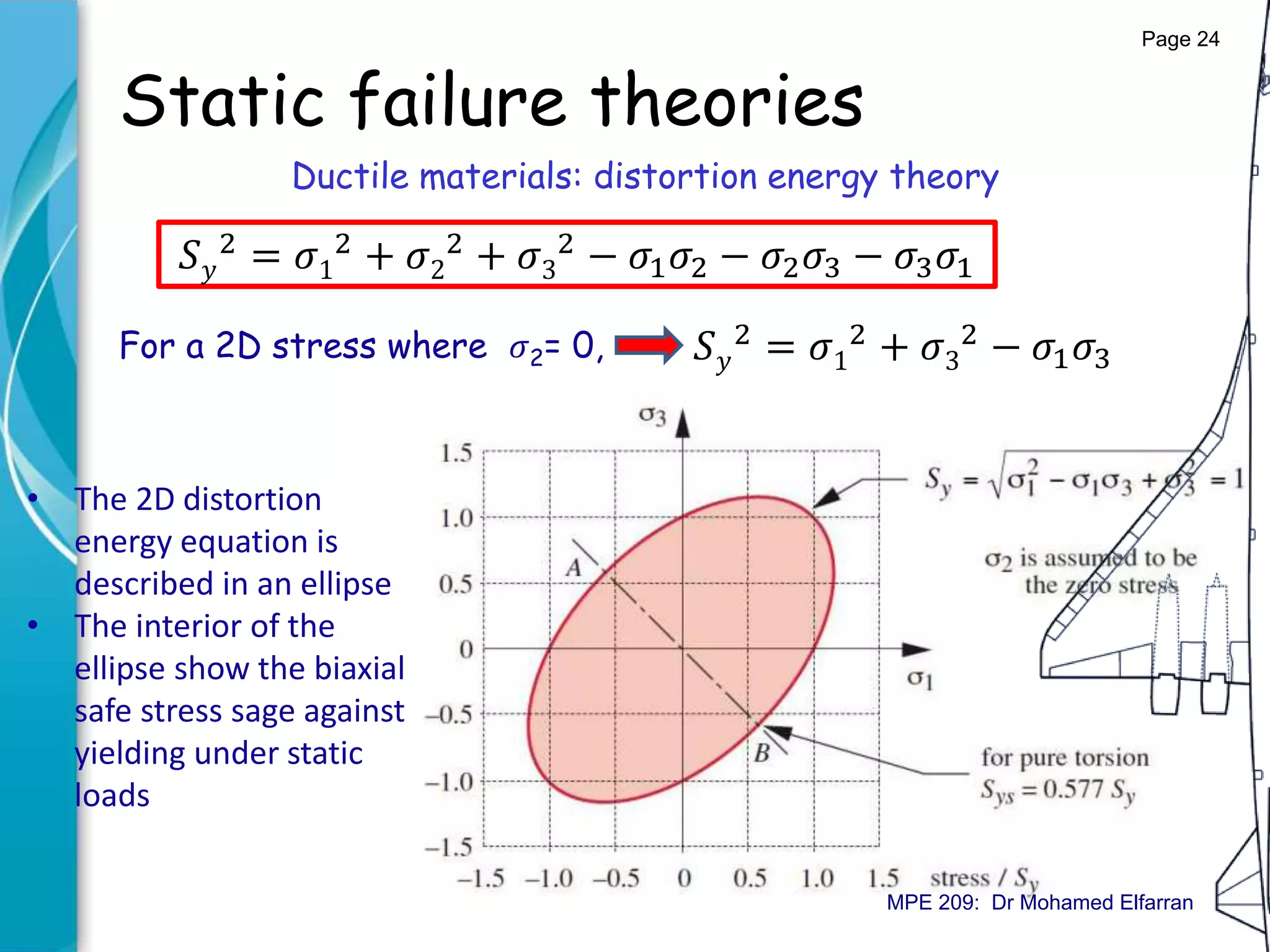

Von Mises effective stress

𝑆 𝑦

2 = [𝜎1

2 + 𝜎2

2 + 𝜎3

2 − 𝜎1 𝜎2 − 𝜎2 𝜎3 − 𝜎3 𝜎1] ≡ 𝜎′ 2

Definition:

𝜎′ = 𝜎1

2

+ 𝜎2

2

+ 𝜎3

2

− 𝜎1 𝜎2 − 𝜎2 𝜎3 − 𝜎3 𝜎1

(Yield surface)

von Mises effective stress

von Mises effective stress: uniaxial stress that would create the

same distortion energy as is created by actual combination of

applied stresses

Page 25

MPE 209: Dr Mohamed Elfarran](https://image.slidesharecdn.com/mpe209lec41-201116171650/75/MEP-209-Design-of-Machine-elements-LEC-4-25-2048.jpg)