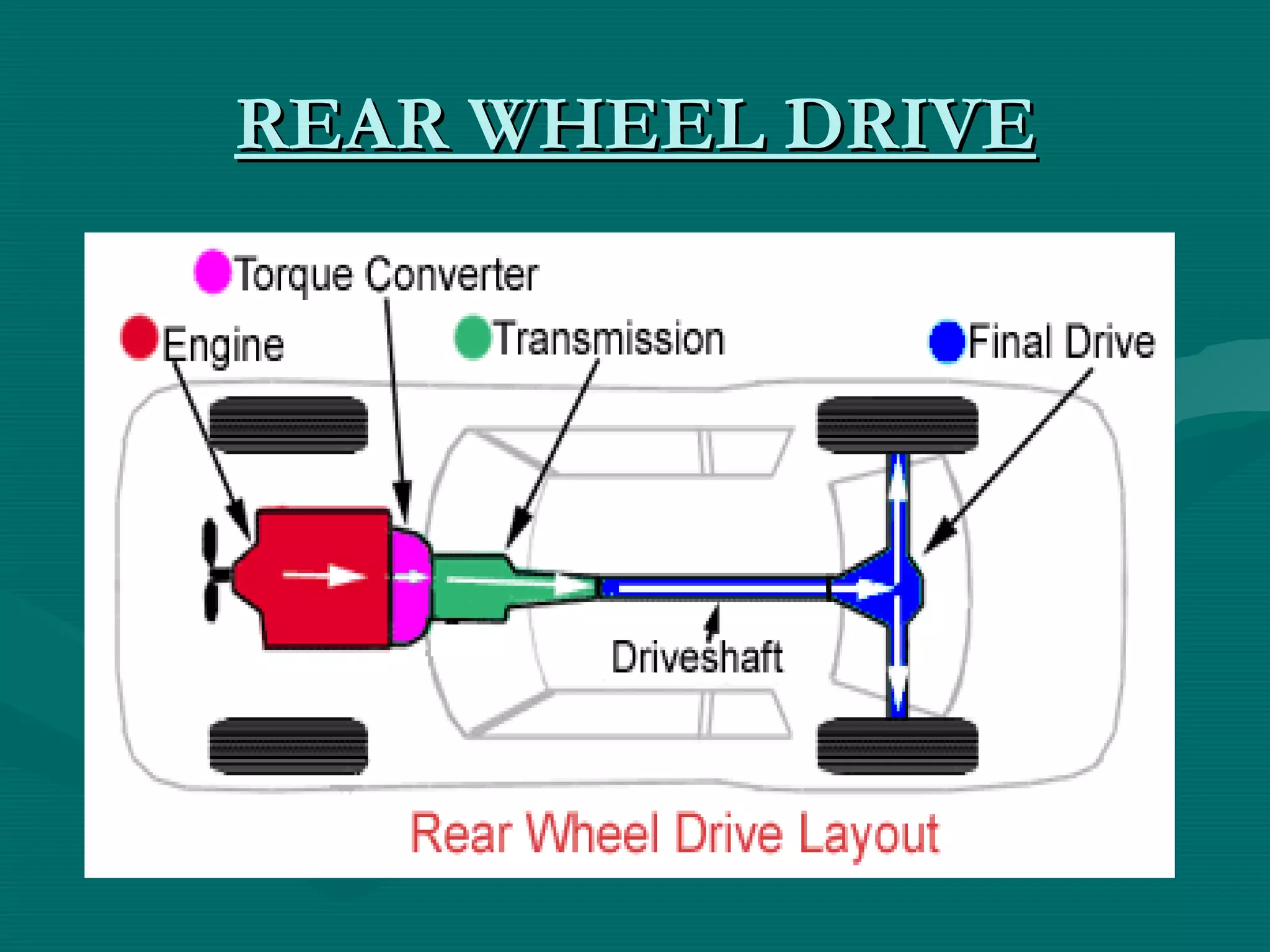

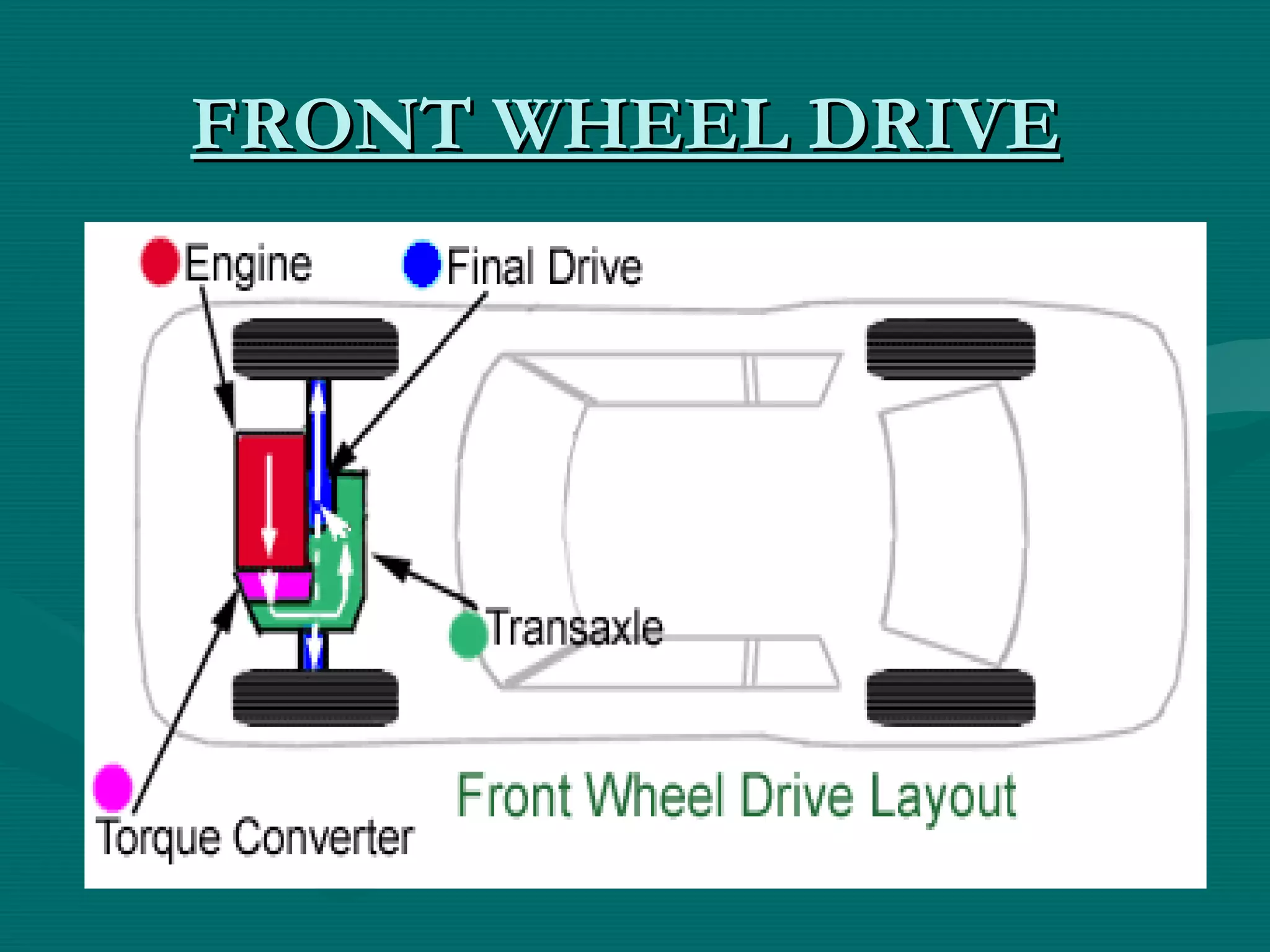

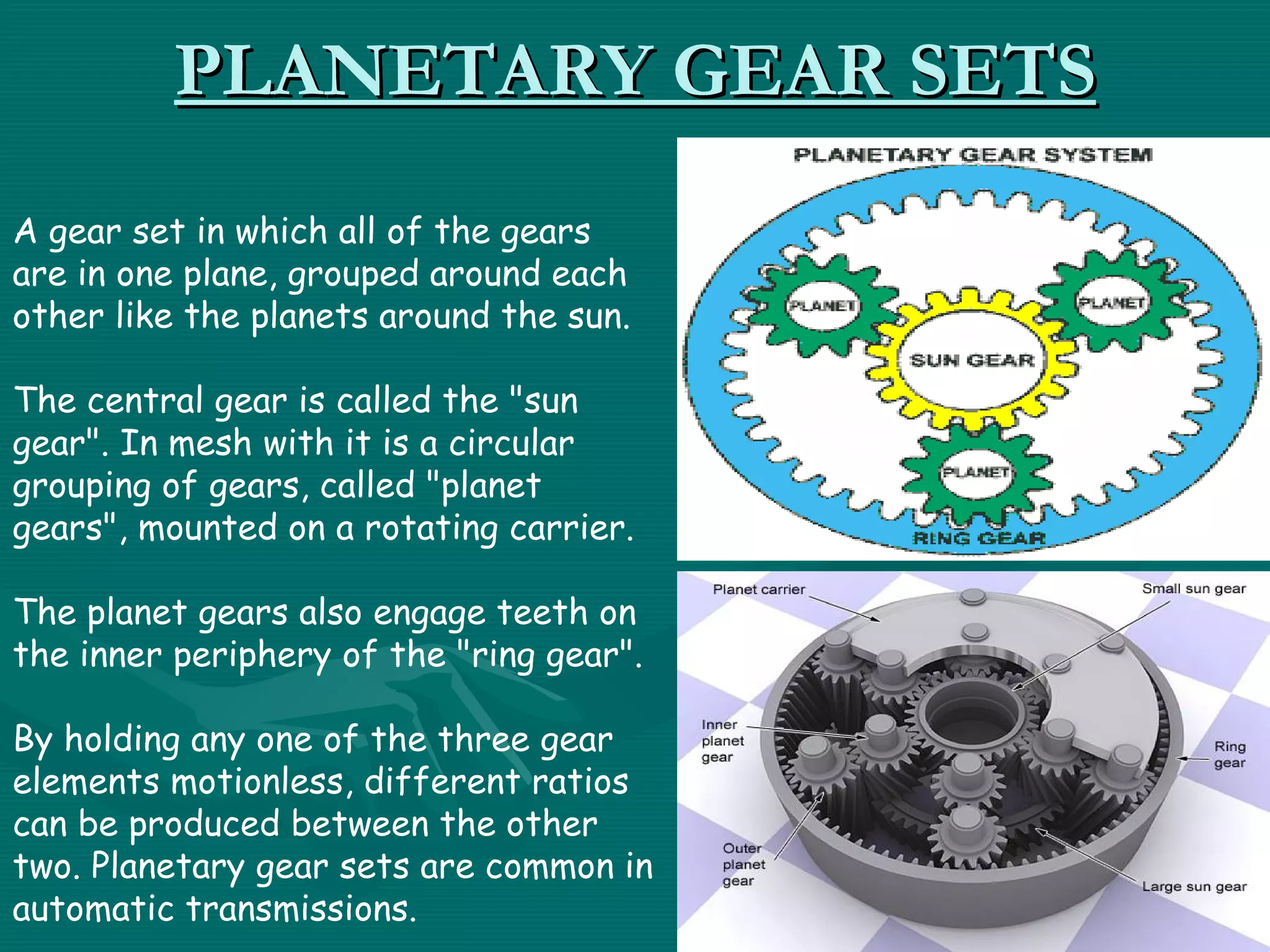

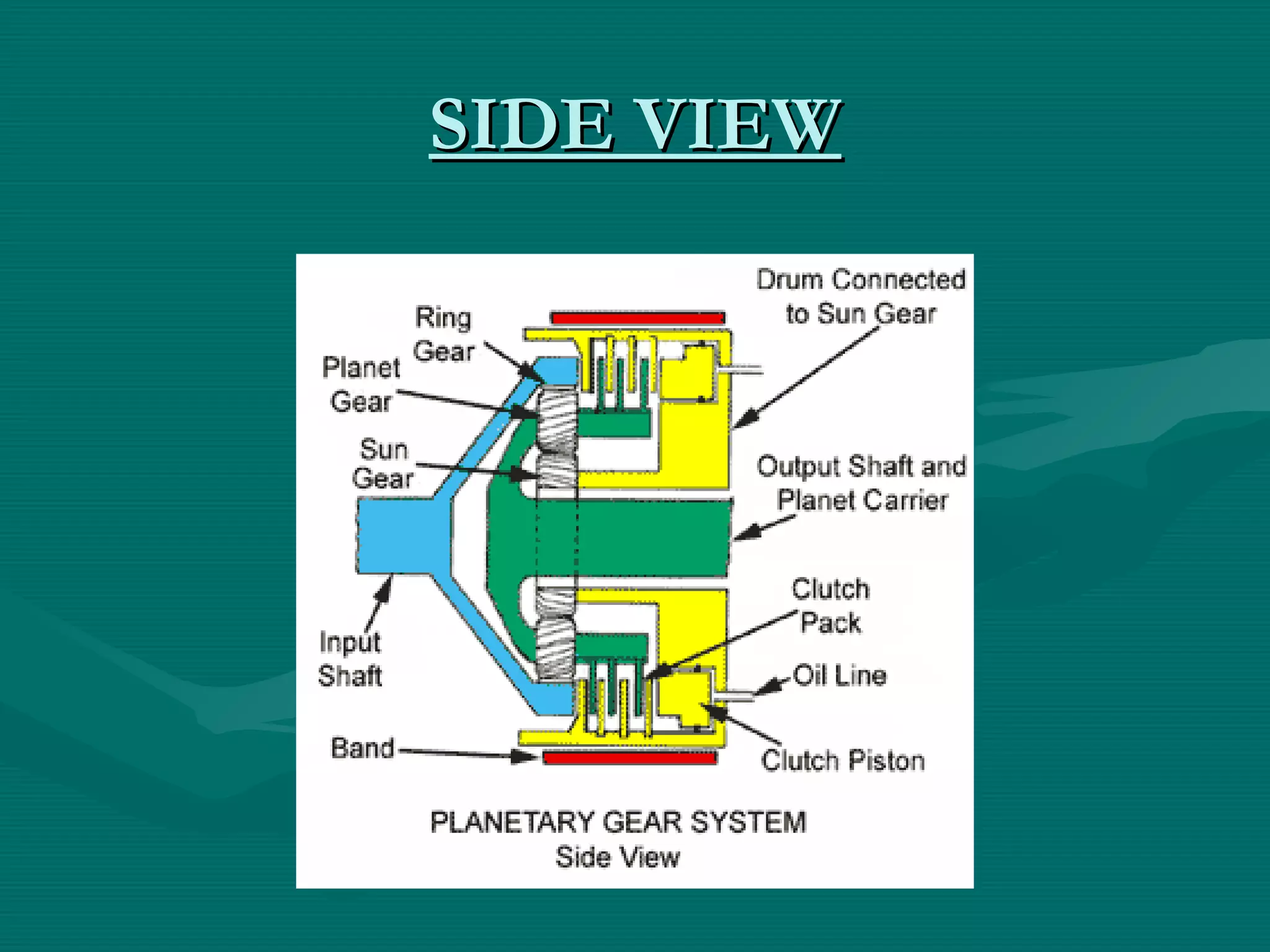

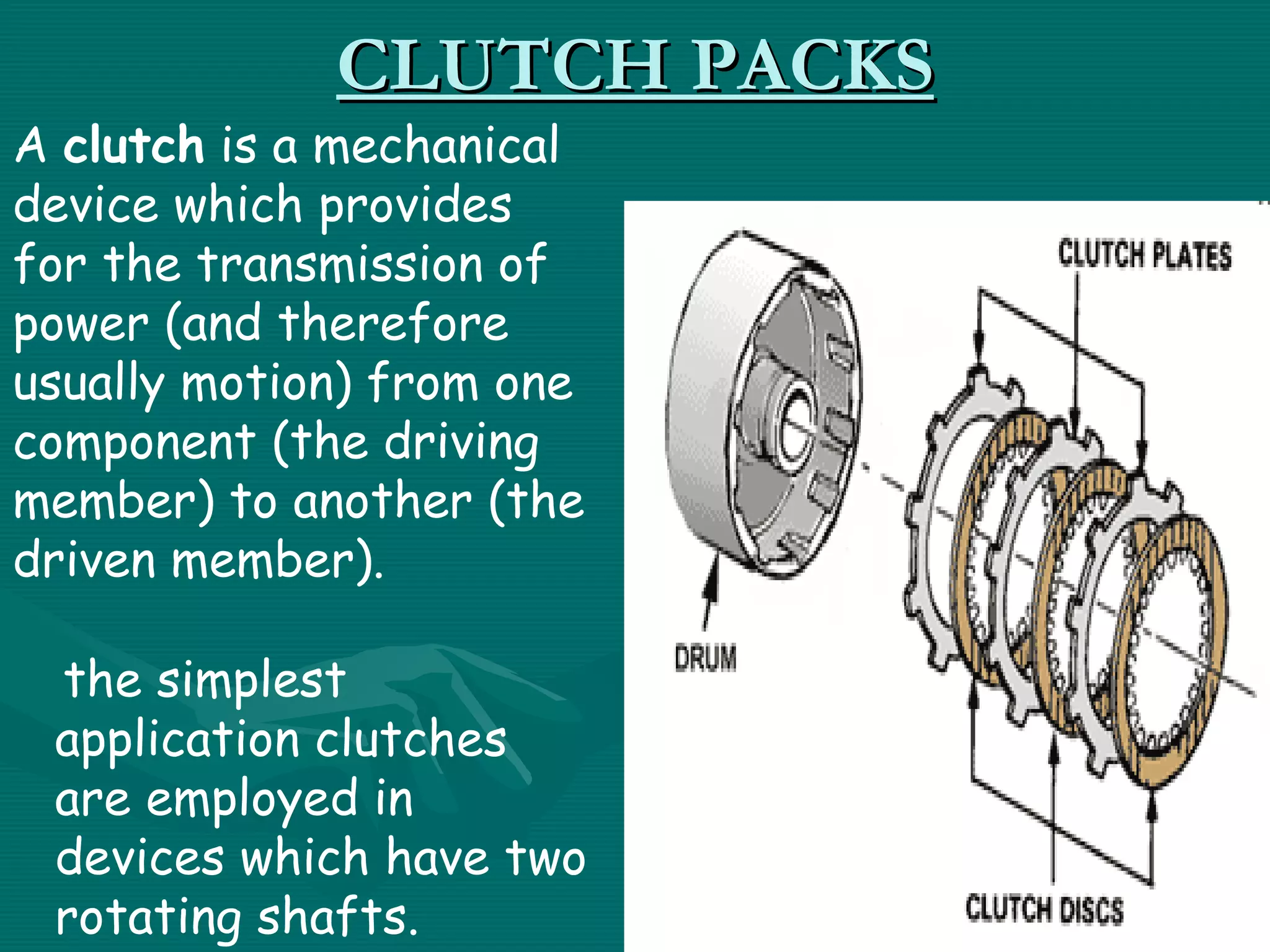

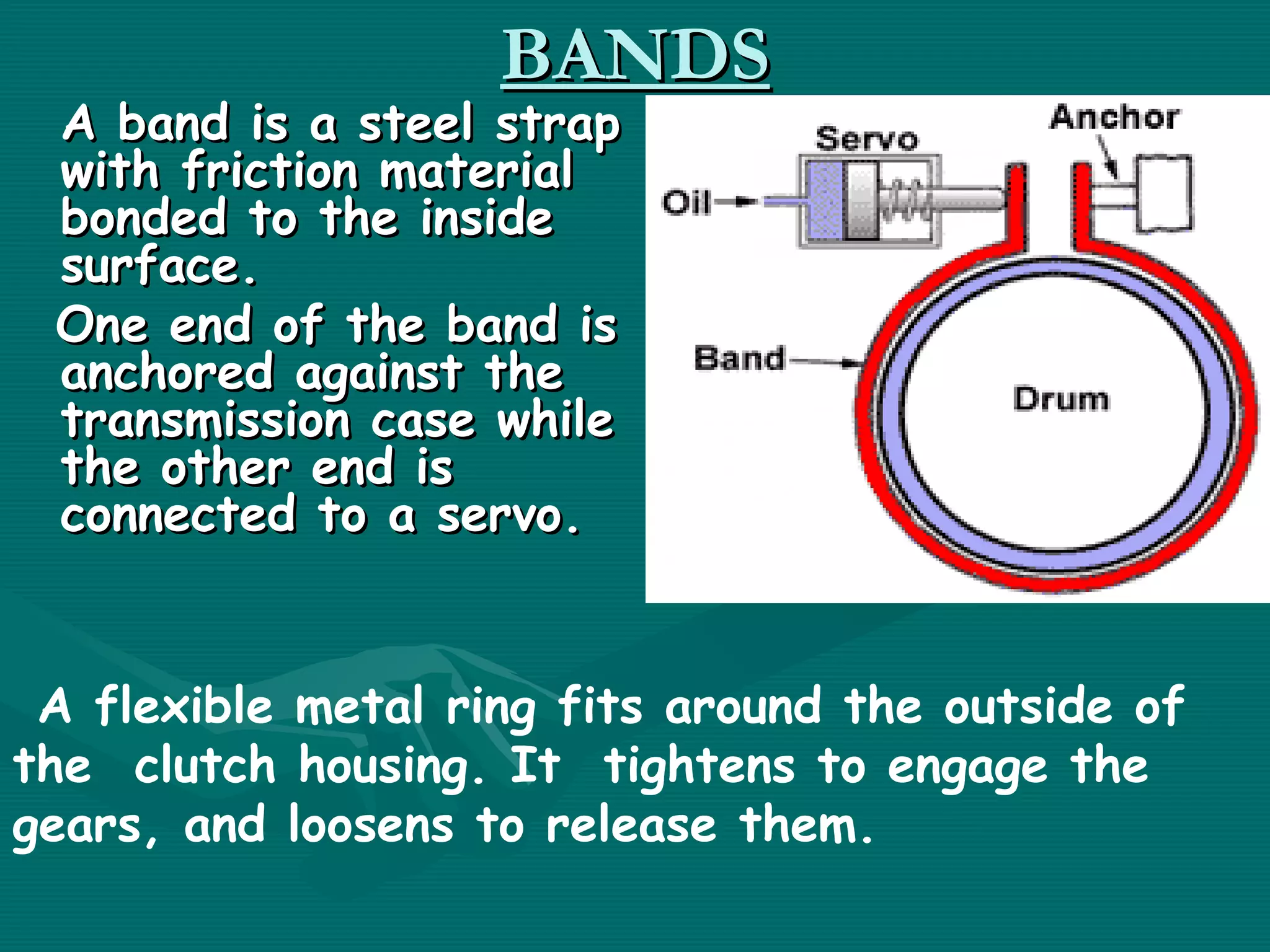

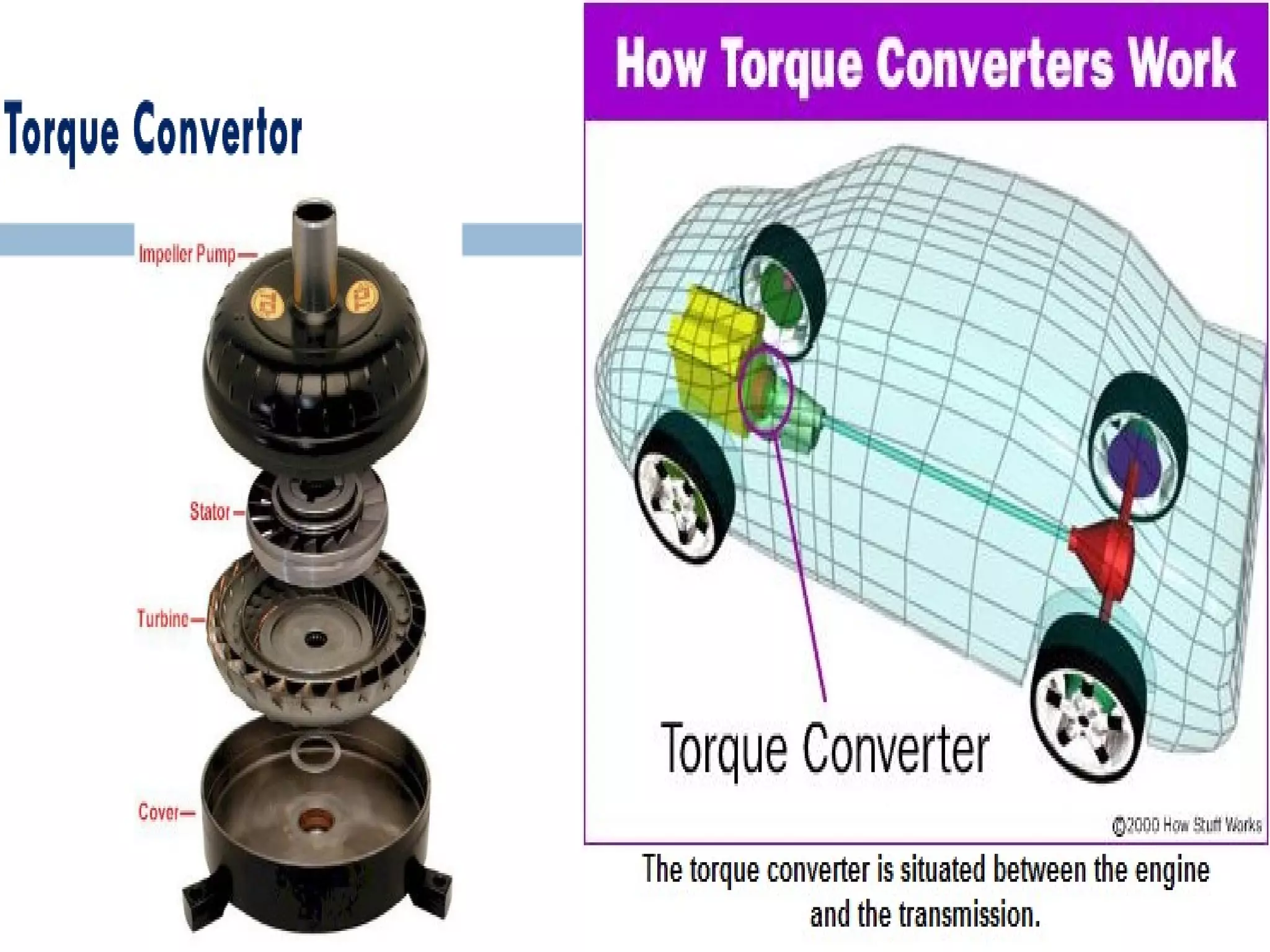

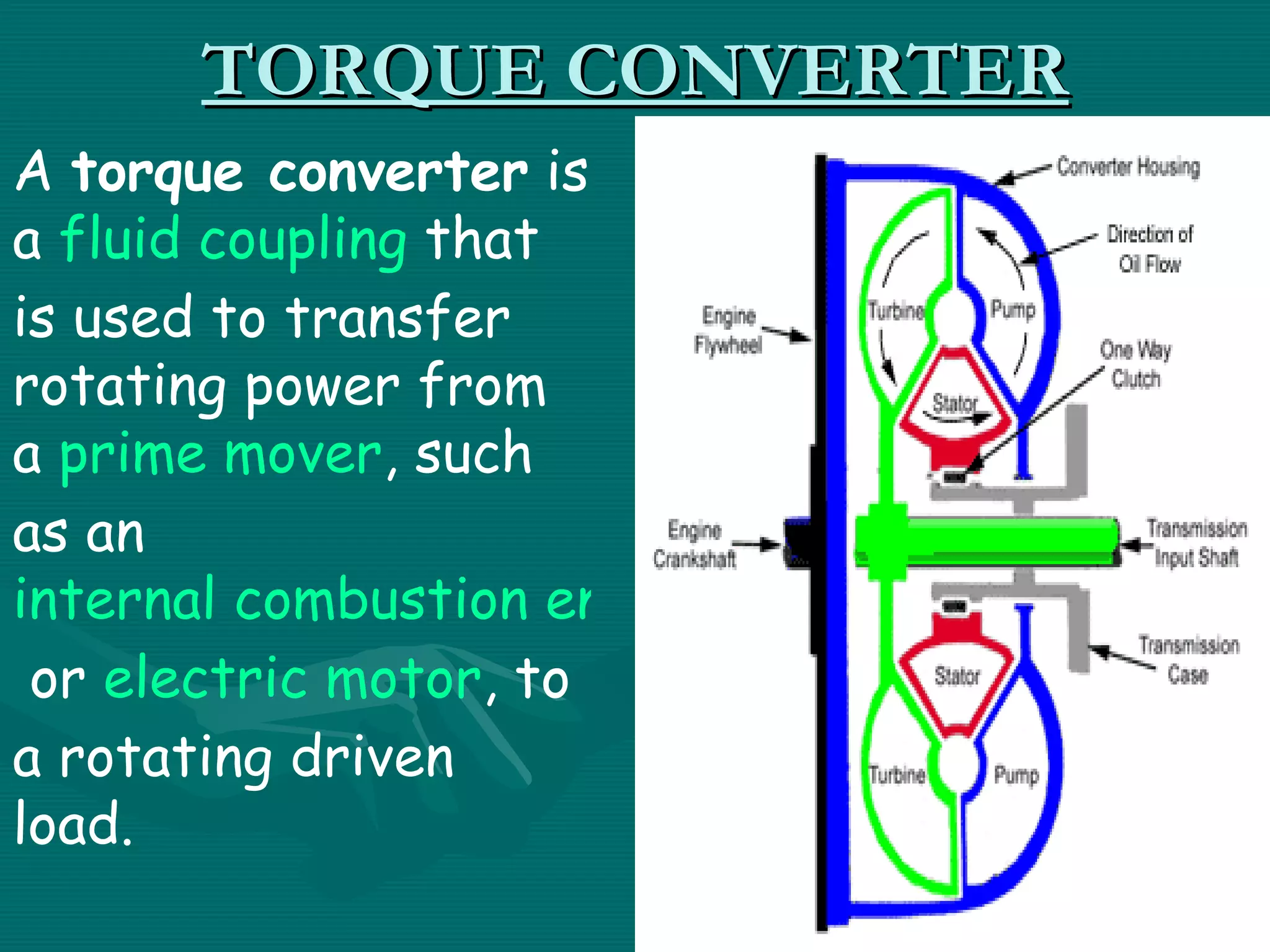

This document is a seminar report on automatic transmission systems submitted by Vijay Kumar, an 8th semester mechanical engineering student at VVCE Mysore. It discusses the key components of automatic transmissions including planetary gear sets, hydraulic systems, torque converters, clutches, bands and computer controls. It also covers rear-wheel drive and front-wheel drive transmissions, common problems, and repair options. The conclusion emphasizes the importance of keeping transmissions and fluid at the proper operating temperature for long life. References include technical websites and manuals.