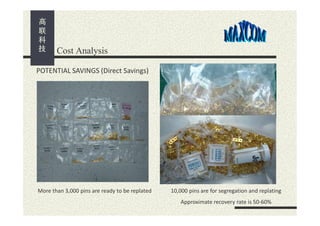

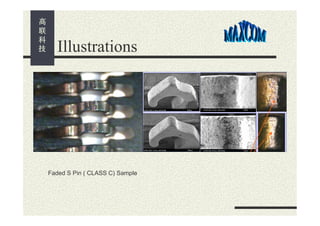

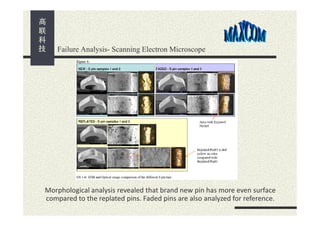

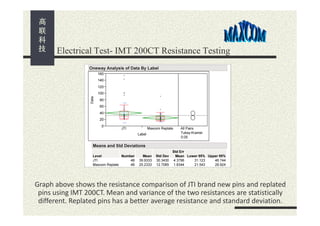

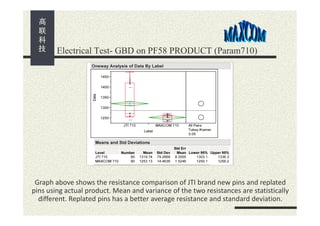

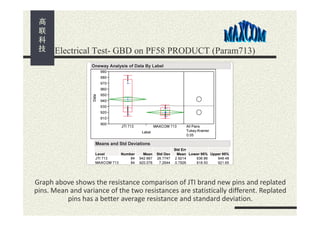

This report evaluates the replating of used contact pins. It finds that replated pins have a courser surface than new pins, leading to better electrical contact. Testing shows replated pins have similar elemental composition as new pins and better contact resistance. Replated pins last 216,000 insertions on average, compared to 250,000 for new pins. The cost savings per replated pin is $0.74. Replating 10,000 pins could yield a potential yearly savings of $10,193 for one high-usage pin model. The report recommends replating for mass production and implementing it for other contact elements.

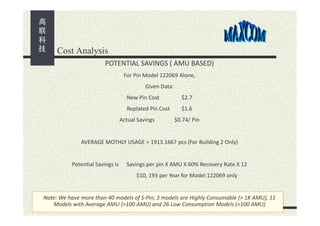

![Cost Analysis

COST SAVING PER PIN

NEW PIN COST PER INSERTION

Given Data:

= $2.7 / 250K insertions

$2.7

= $0.0000108 / insertions

250K insertions

NUMBER OF GAINED INSERTIONS

New Pin Cost

New Pin Life

$1.6

= Replated Pin Life – Break even point

216.335K insertions

=68, 152 insertions

Replated Pin Cost

Replated Pin Life

ACTUAL SAVINGS PER PIN

BREAK EVEN POINT

Let “Break Even Point” = X

X

=[ $1.6 (250K)]/ $2.7

=148,148 insertions

CHECKING:

SAVINGS if actual replated pin life is also 250K

= $2.7- $1.6

=$1.1 per pin

= Number of gained insertions X Cost per

Insertions

=68,187 insertions X $0.0000108/ insertions

=$0.74 per pin

250K insertions- Break Even Point ( 148,148) = 101,852 insertions

101,852 X $0.0000108

=$1.1 per pin](https://image.slidesharecdn.com/testpinreplatingevaluationreport-131013014708-phpapp02/85/Test-pin-replating-evaluation-report-12-320.jpg)