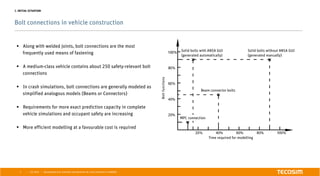

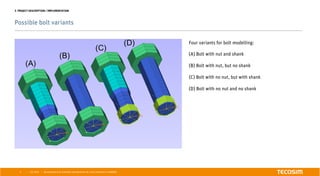

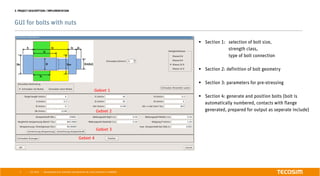

The document describes the development of an automatic bolt generator for crash simulations using Abaqus, aiming to improve the modeling of bolt connections in vehicle structures due to increasing demands for accuracy in safety predictions. The project includes programming a graphical user interface to facilitate the automatic generation of bolt models across various sizes and property classes, ensuring that results align with theoretical metrics. A validated material model with failure criteria was produced, allowing for efficient pre-loading calculations and positioning of bolts with minimal user input.