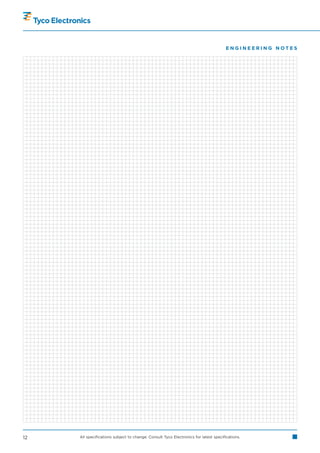

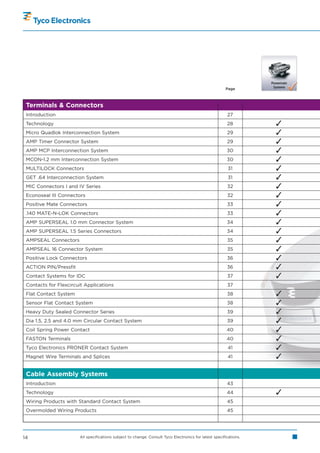

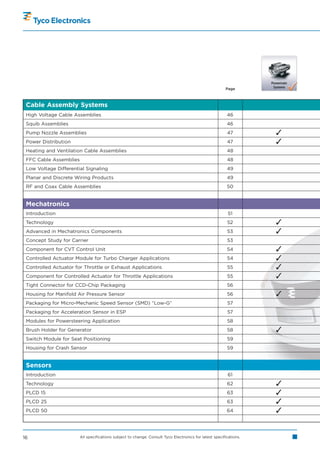

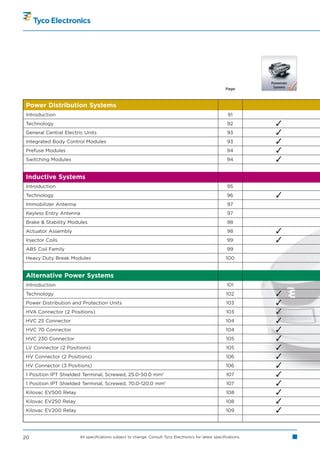

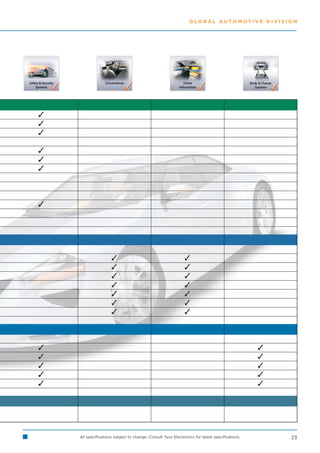

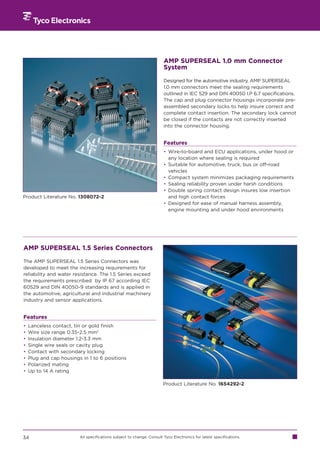

This document discusses Tyco Electronics' automotive products and services. It provides an overview of Tyco Electronics' global automotive division and their portfolio of electronic components used in automotive applications. This includes connector systems, relays, sensors, fiber optic products, wire and cable. The document also describes Tyco Electronics' online resources and product literature available to customers.