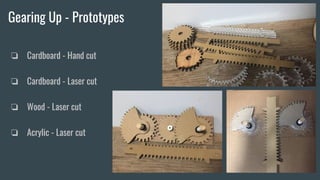

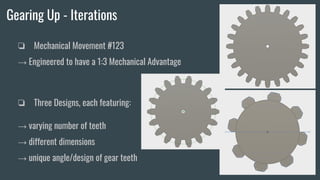

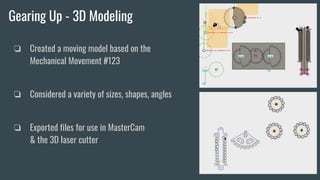

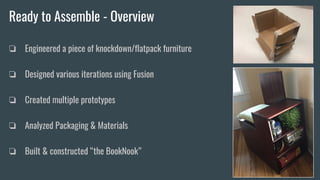

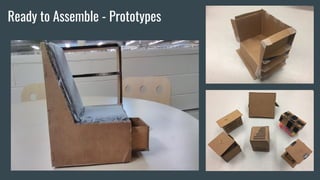

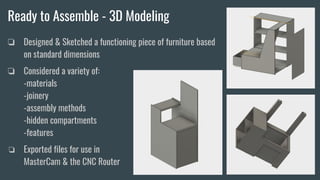

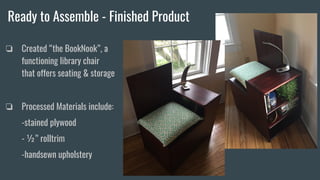

This portfolio document outlines Kayla Barbour's work in the TAD 330 course. It includes sections on designing with Fusion 360 software, individual projects on gear mechanisms and designing a piece of knockdown furniture, and prototypes and final products created. The gearing mechanisms project involved sketching designs, creating prototypes, and building a thread spooler. The furniture design project included sketching iterations, making prototypes, and constructing a finished "BookNook" library chair. Overall, the course exposed students to design software, new technologies, design thinking skills, and career applications in sustainable design.