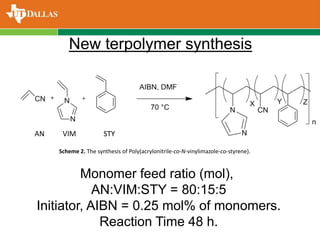

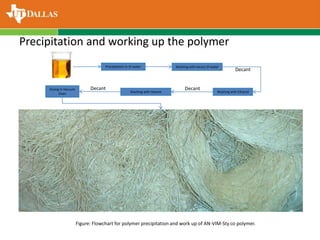

1) A poly(acrylonitrile-co-N-vinylimidazole-co-styrene) terpolymer was synthesized via free radical polymerization using acrylonitrile, N-vinylimidazole, and styrene monomers.

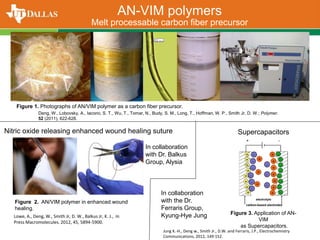

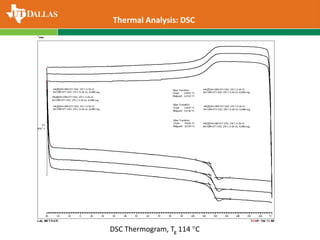

2) The terpolymer has a glass transition temperature of 114°C and degrades at 310°C. It leaves a char yield of 44% and is melt processable.

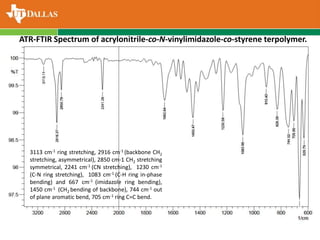

3) The terpolymer was characterized using NMR, FTIR, TGA, and DSC to determine its composition, structure, thermal properties, and potential applications such as carbon fiber precursors, wound healing sutures, and supercapacitors.