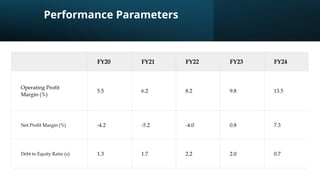

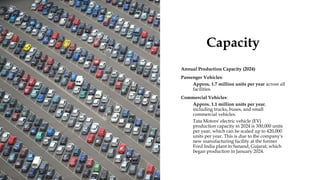

Tata Motors focuses on innovation, international expansion, and diverse product lines to enhance customer satisfaction and operational efficiency while aiming for sustainability. The company is committed to achieving net zero GHG emissions by 2040 and plans to become debt-free in India by FY25, with a robust capacity for producing passenger and commercial vehicles, including a significant increase in electric vehicles. Its supply chain leverages advanced technologies such as blockchain and IoT, ensuring resilience and efficiency across global operations.