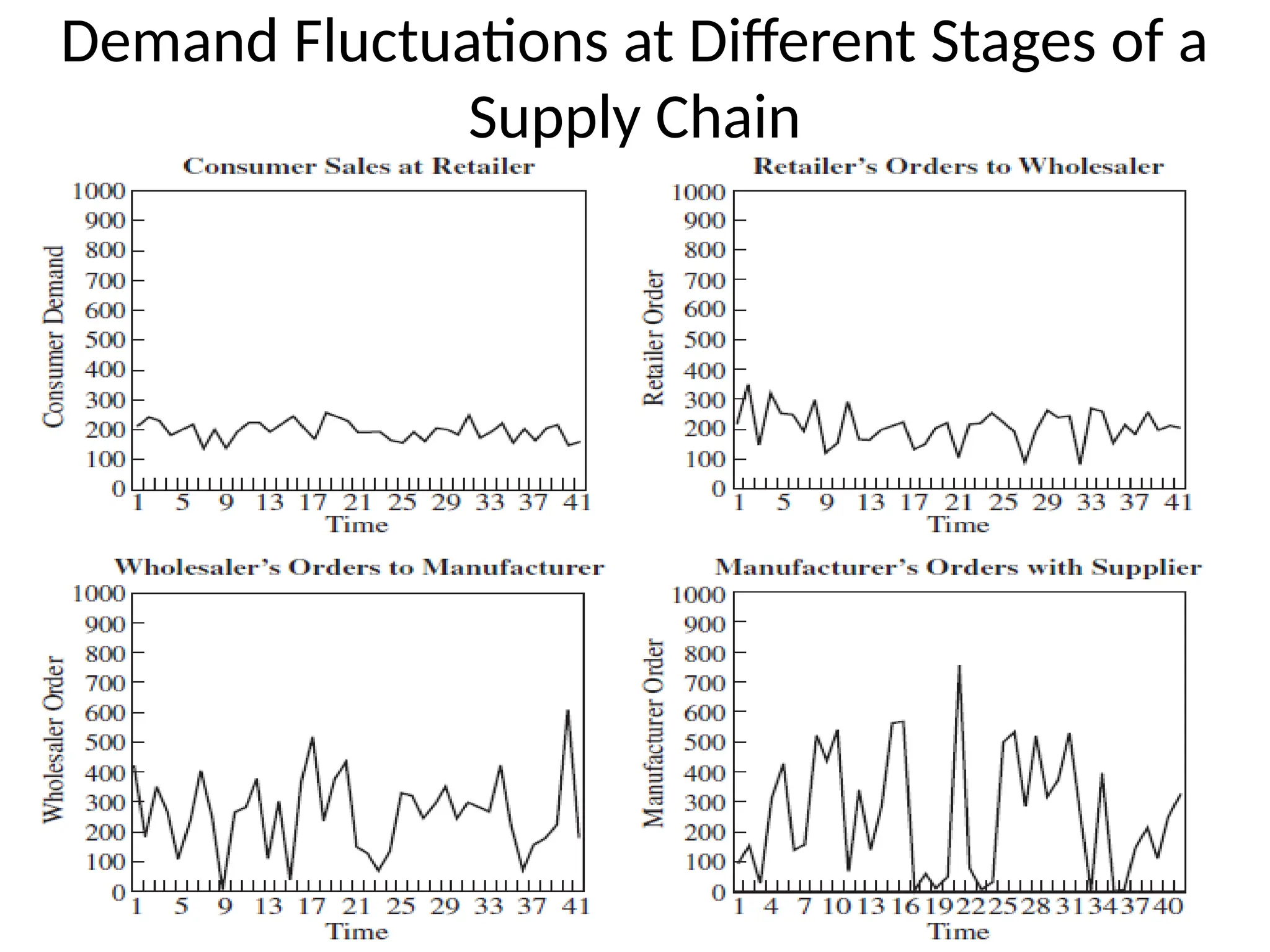

Module 4 discusses the importance of supply chain coordination, highlighting issues such as the bullwhip effect, obstacles to coordination, and strategies for improvement like continuous replenishment and vendor-managed inventories. Key managerial levers include aligning goals, improving information visibility, and building trust among supply chain partners to enhance performance and profitability. The module emphasizes a demand-driven supply chain approach that prioritizes real-time customer demand to optimize inventory and improve efficiency.