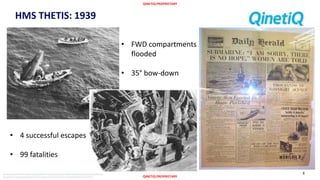

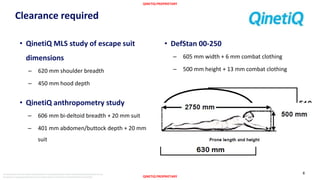

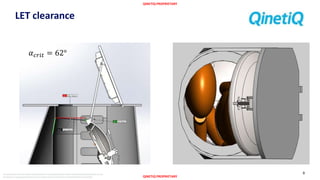

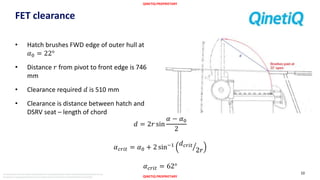

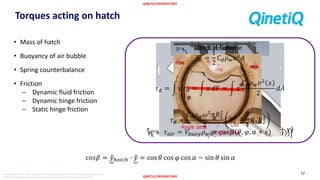

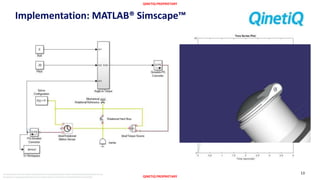

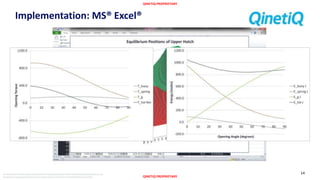

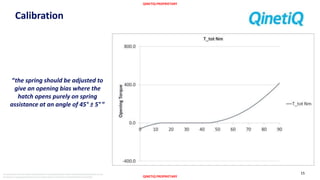

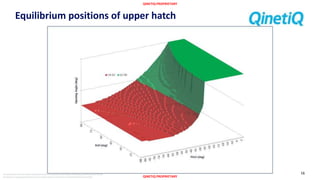

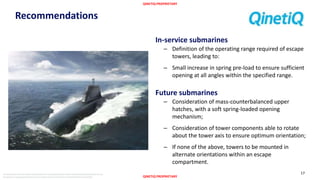

The document discusses submarine escape systems and the challenges associated with egress from escape towers, including equipment trials and physiological considerations. It highlights the risks of decompression sickness, the importance of clearance for escape suits, and engineering aspects of escape hatches. Additionally, it provides recommendations for both current and future submarine designs to improve escape mechanisms and safety measures.