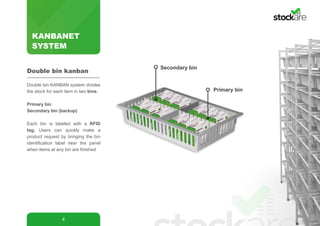

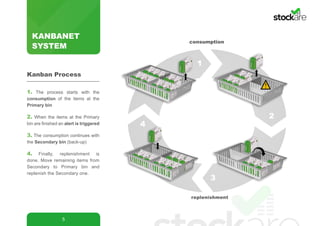

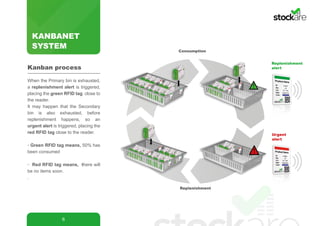

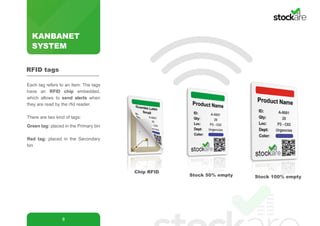

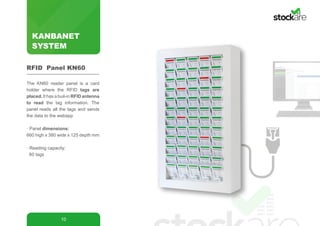

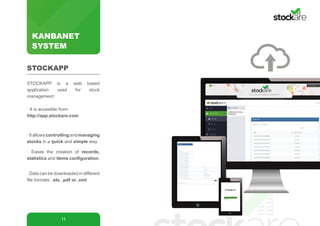

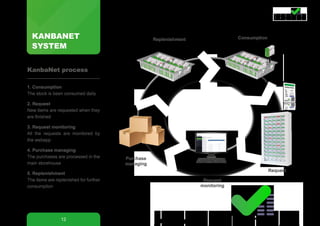

Kanbanet is an RFID-based stock management solution that improves stock organization and control by ensuring products are always available and minimizing issues such as stockouts and expired products. It utilizes a double bin system with RFID tags for efficient monitoring and replenishment of inventory. The accompanying web application, StockApp, facilitates quick management and data analysis of stock items.