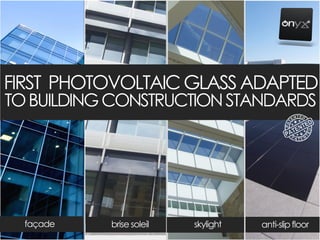

The document outlines the specifications and features of photovoltaic glass used in building construction, including various sizes, thicknesses, and transparency levels. It highlights the multifunctional benefits of these materials in enhancing architectural value while providing solar energy generation capabilities. Additionally, it details compliance with international standards and offers marketing support for distributors.