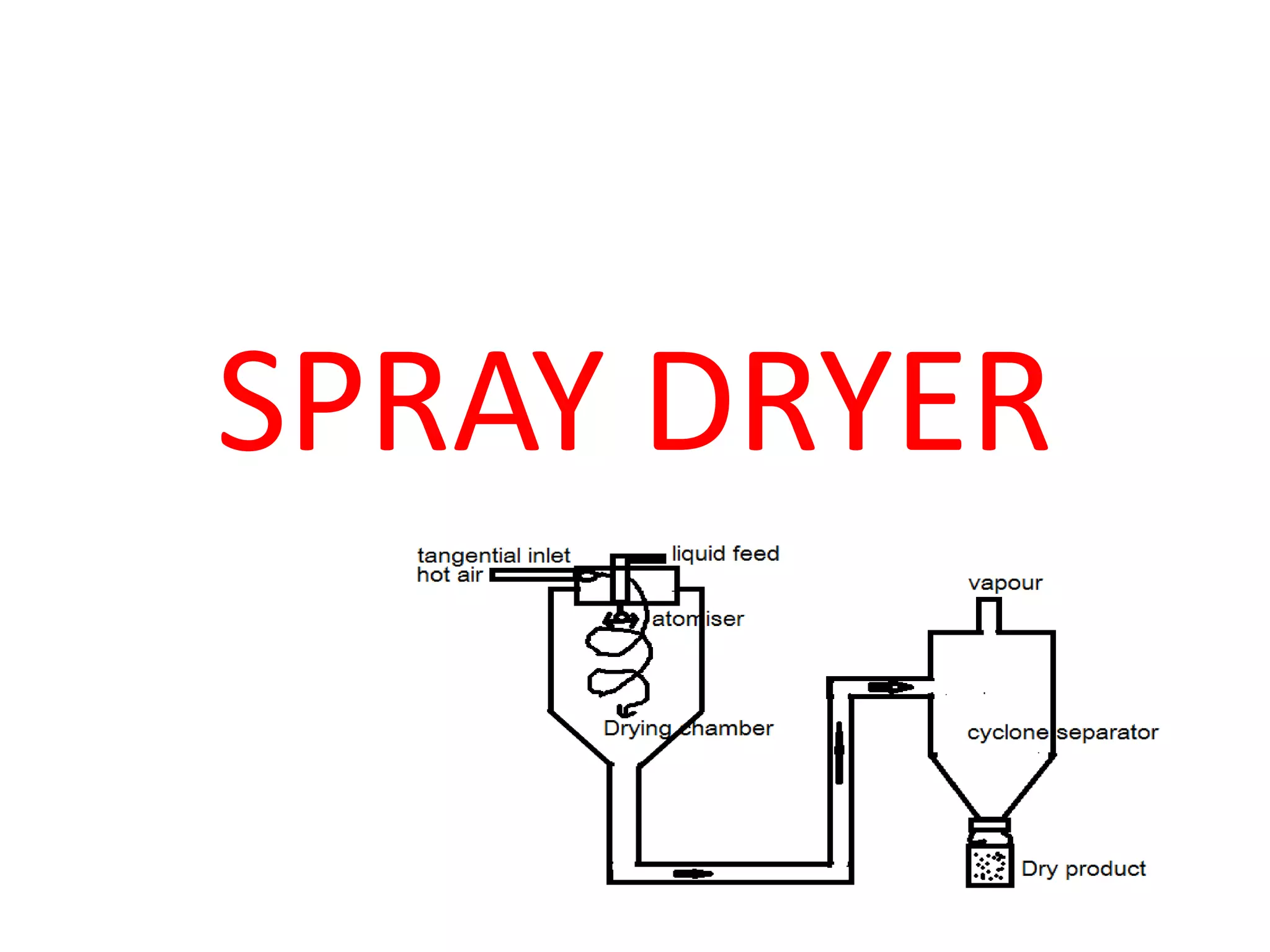

The document describes the working of a spray dryer. A spray dryer uses atomization to form fine liquid droplets that are then dried into powder particles by hot gas. The liquid is sprayed into a drying chamber and the droplets move in a helical path as hot air evaporates the moisture, forming dry particles within seconds. The dried particles are then recovered at the bottom while the hot air exits through the top. Spray drying allows rapid, continuous drying of heat-sensitive materials and produces free-flowing particles of uniform size.