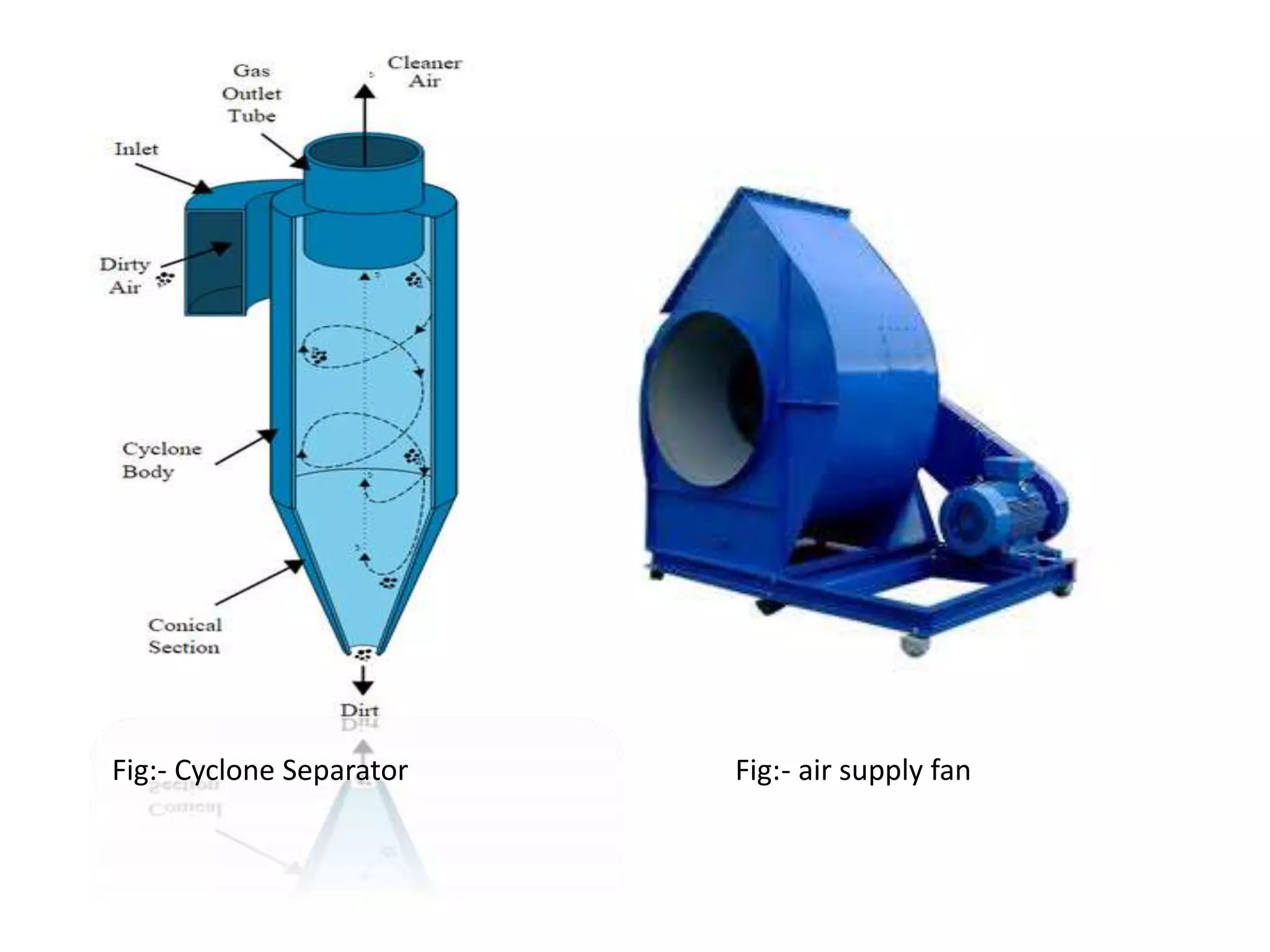

The document discusses the design and operation of a two-stage spray dryer with a fluidized bed dryer, emphasizing the drying process, including atomization and air flow considerations. It highlights the advantages of spray drying such as rapid processing and ability to maintain product quality while also addressing challenges like high equipment costs and energy consumption. The conclusion stresses the importance of effective process control for producing quality dairy powders and concentrated products.