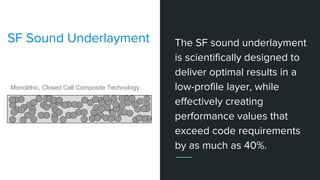

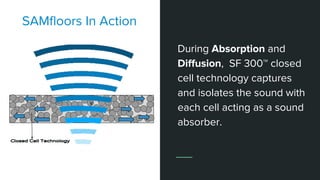

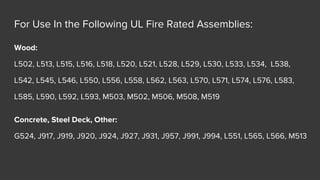

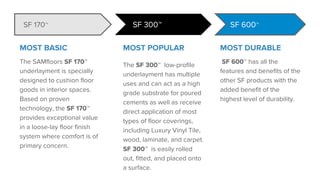

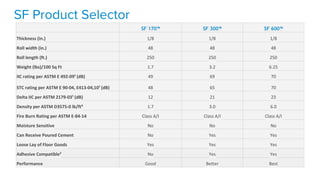

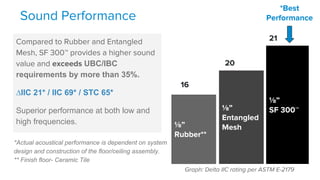

SF Products provide sound control solutions for floor/ceiling assemblies using a proprietary composite technology. Their SF 300 product features a lightweight, monolithic layer that provides superior sound performance with IIC ratings up to 70 and STC up to 67, exceeding code requirements by over 40%. It allows for direct attachment of floor goods and is suitable for use in UL fire rated assemblies.