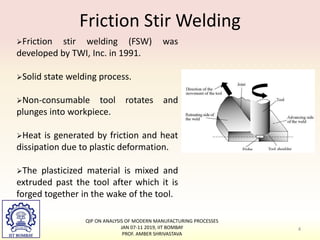

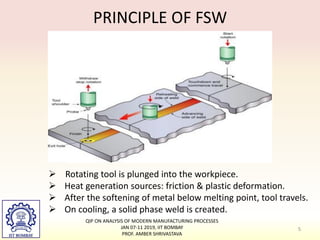

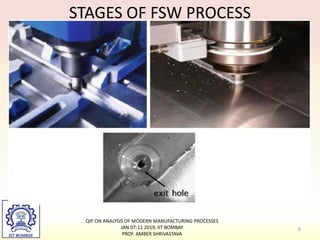

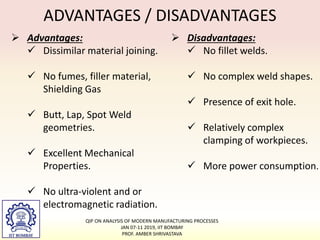

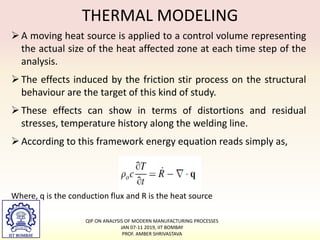

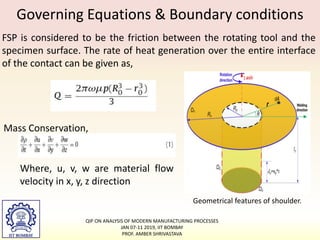

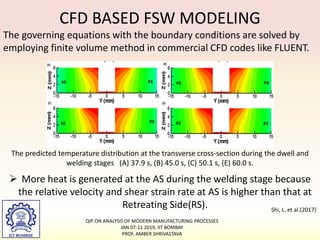

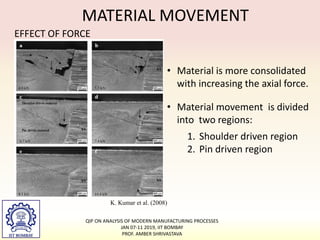

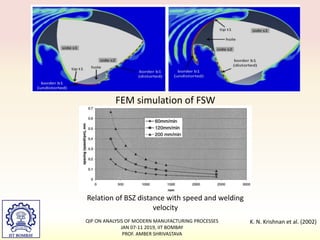

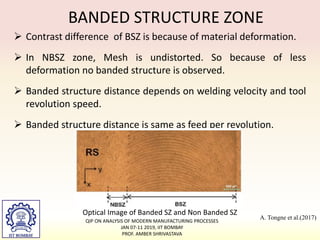

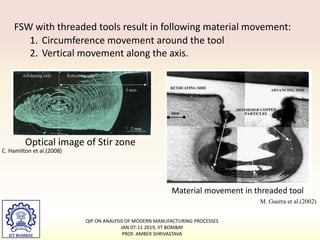

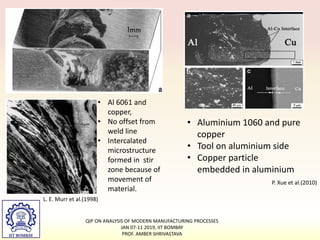

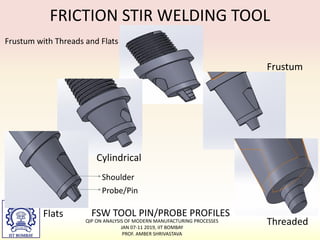

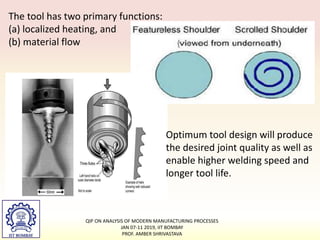

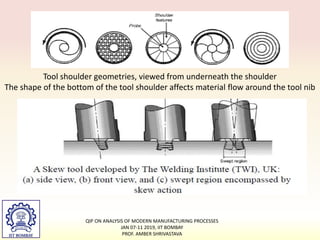

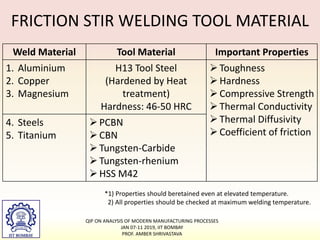

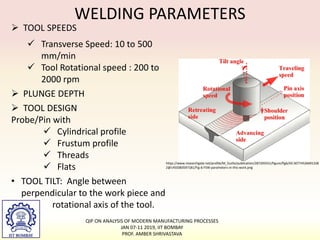

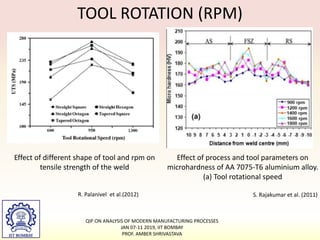

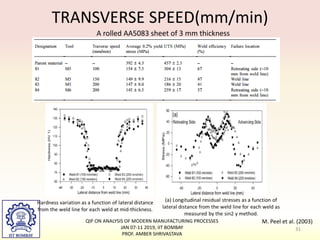

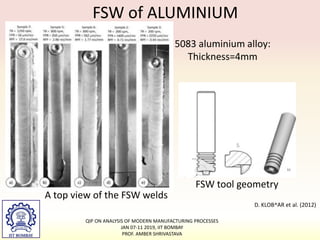

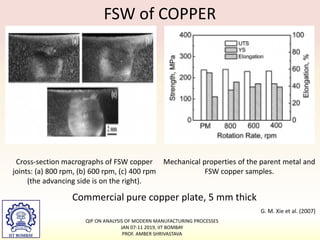

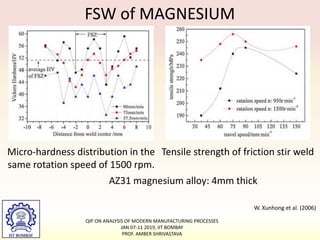

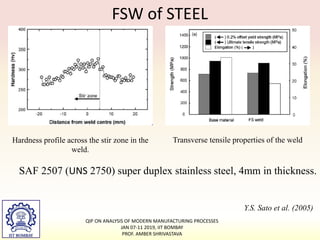

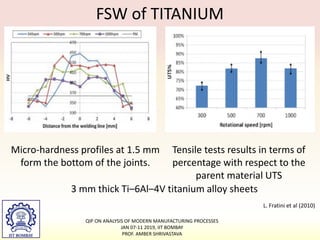

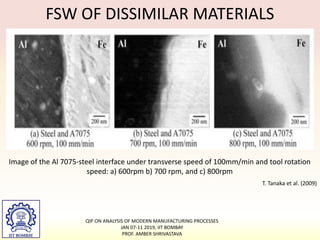

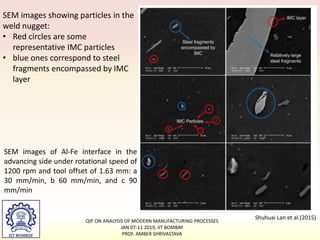

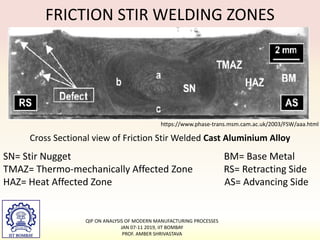

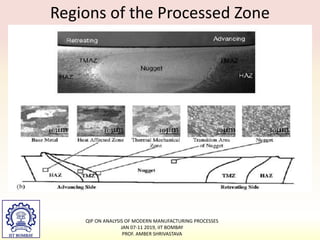

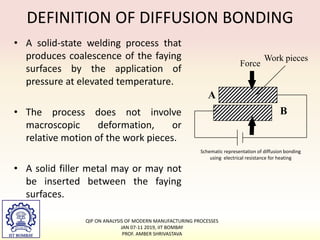

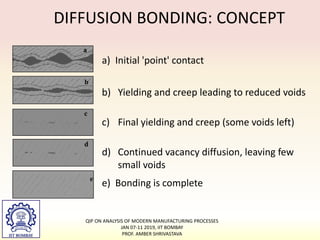

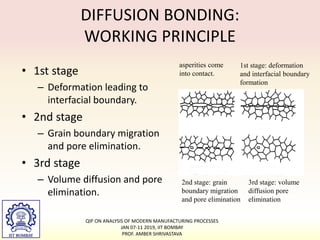

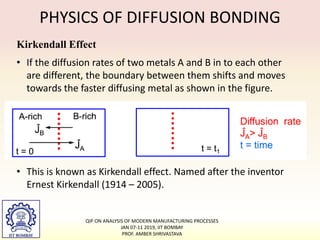

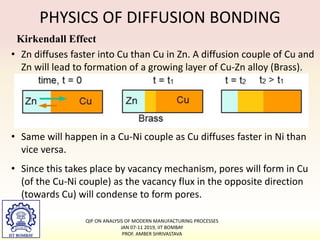

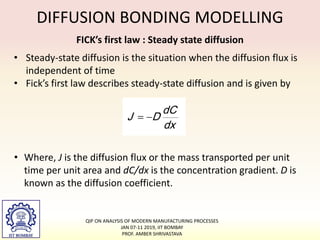

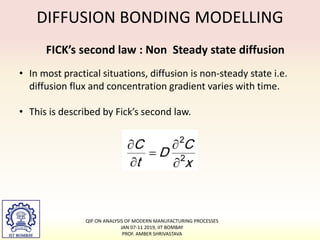

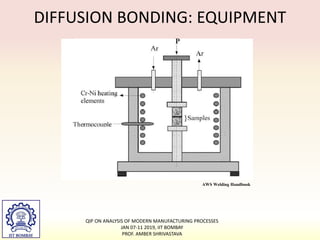

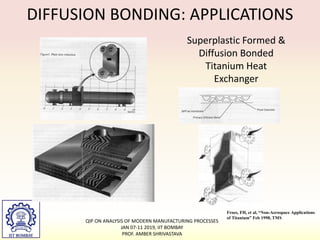

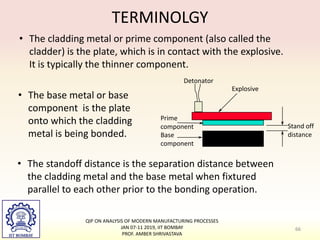

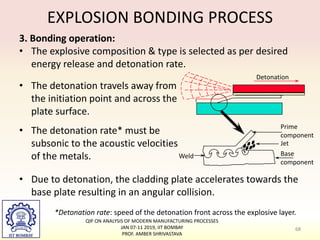

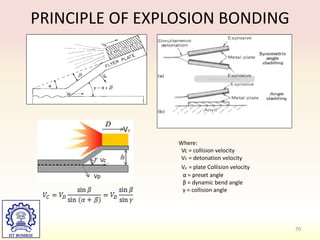

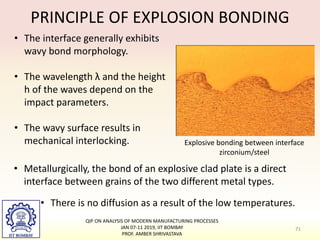

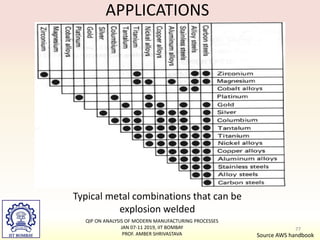

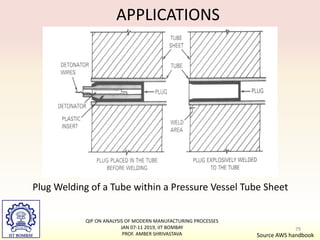

The document discusses solid-state joining processes used in modern manufacturing, which do not involve melting the workpieces. It details various techniques such as friction stir welding and diffusion bonding, emphasizing their mechanisms, advantages, disadvantages, and applications across industries like aerospace and transportation. Additionally, it covers thermal modeling and welding parameters critical for optimizing the joining process.