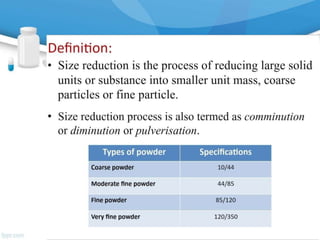

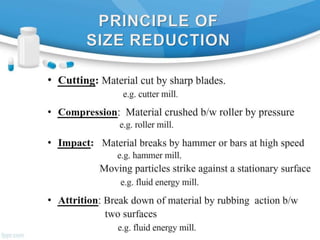

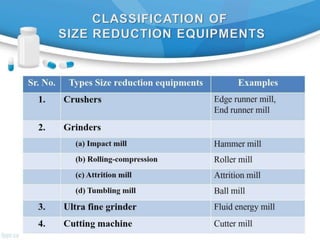

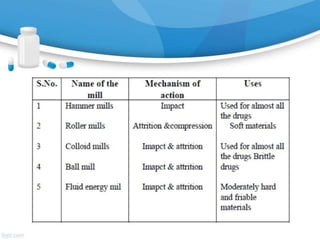

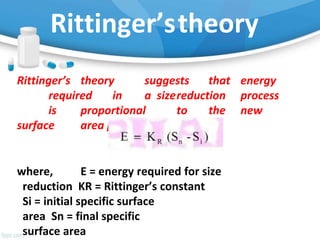

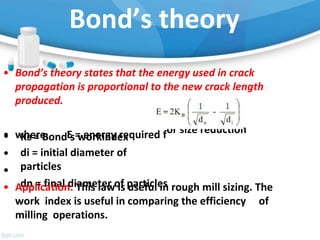

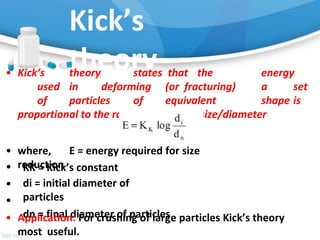

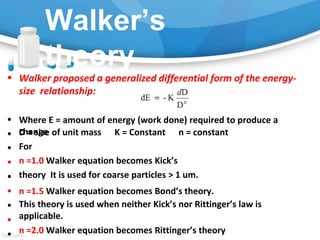

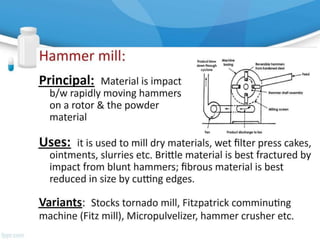

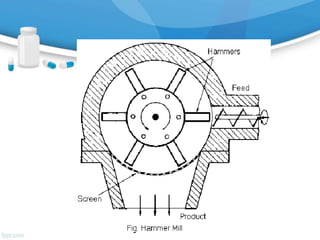

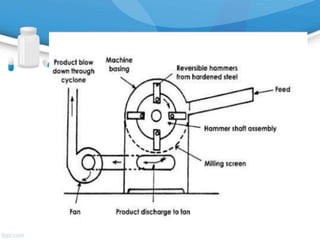

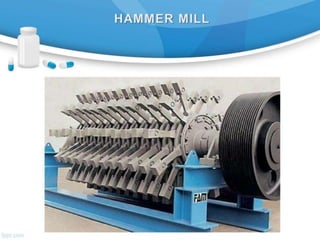

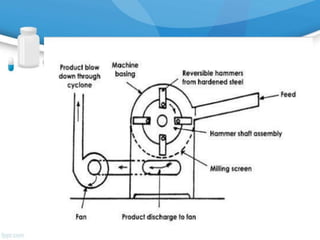

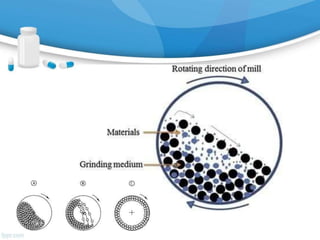

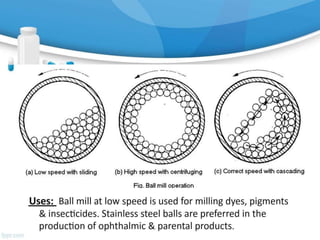

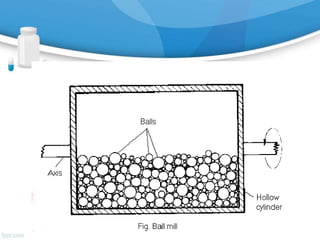

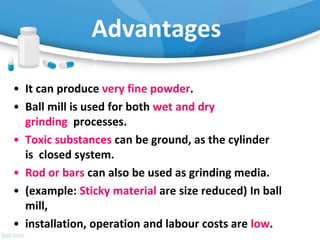

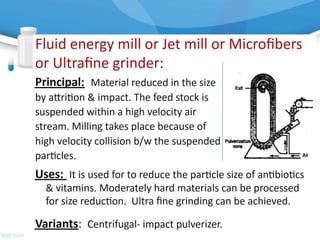

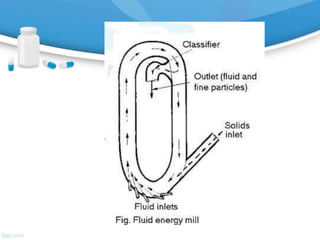

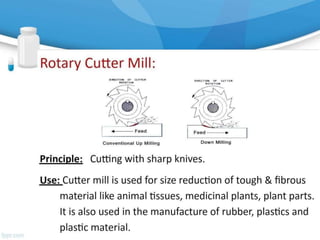

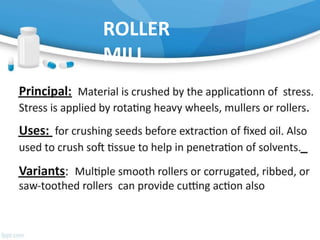

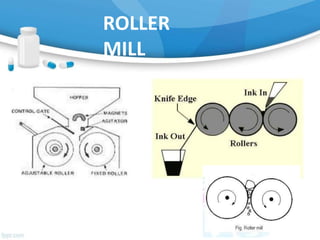

The document discusses various theories of size reduction, including Rittinger's, Bond's, Kick's, and Walker's theories. It also covers different types of equipment used for size reduction, including hammer mills, ball mills, and roller mills. Rittinger's theory suggests energy required is proportional to new surface area created. Bond's theory states energy used for crack propagation is proportional to new crack length. Kick's theory relates energy to ratio of size change, and Walker's theory generalized the energy-size relationship. Advantages and disadvantages of hammer mills, ball mills, and roller mills are provided.