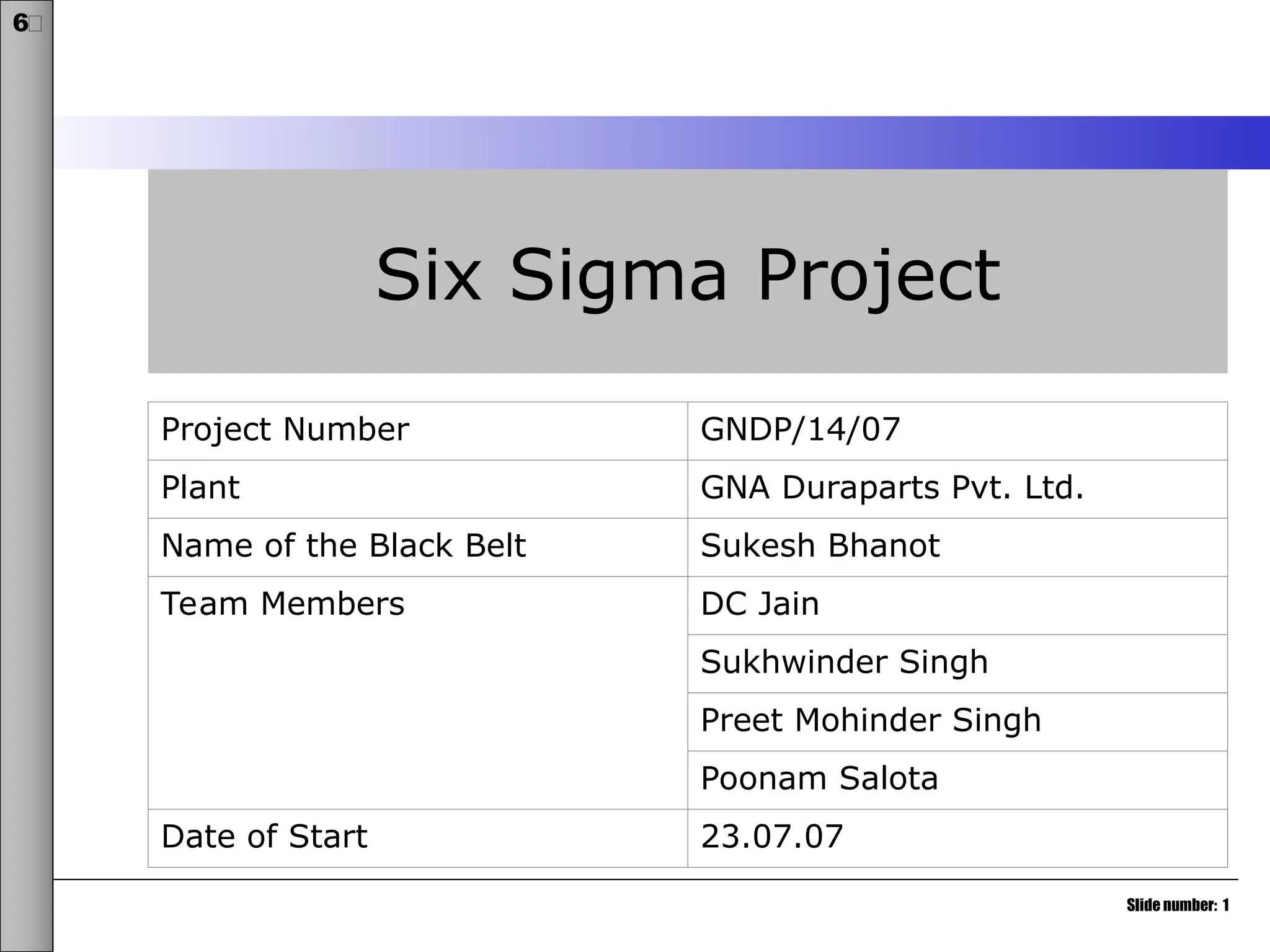

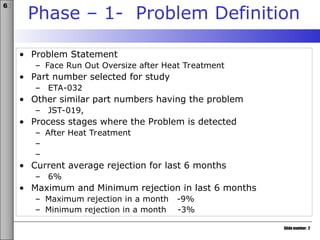

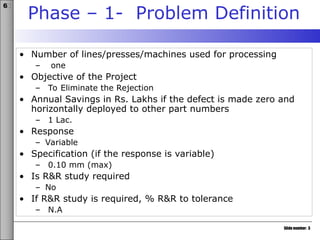

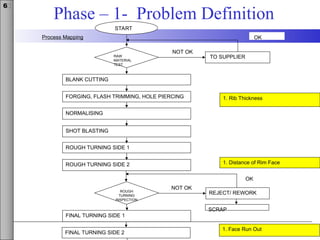

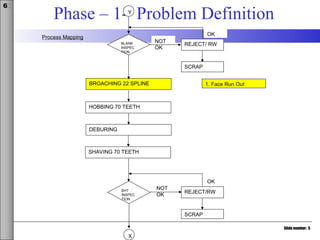

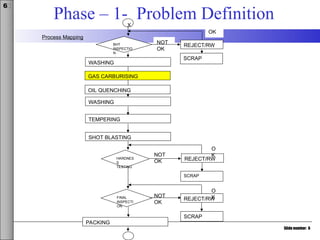

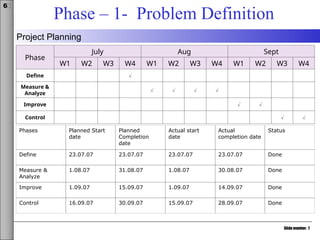

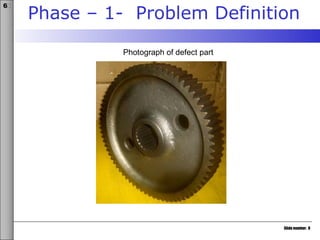

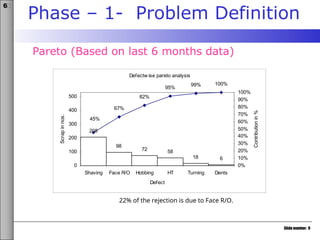

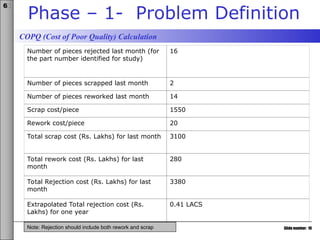

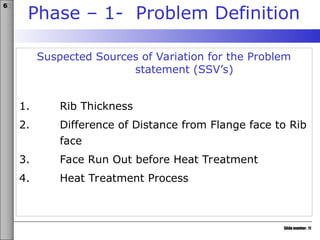

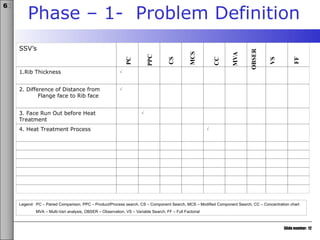

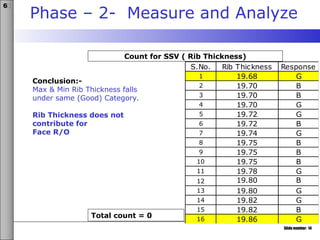

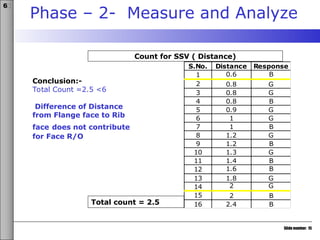

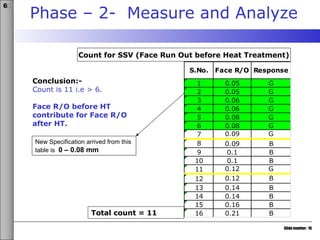

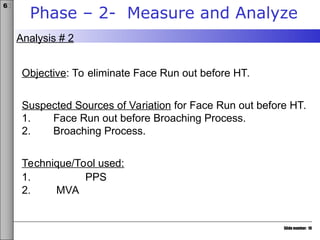

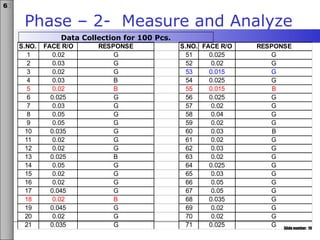

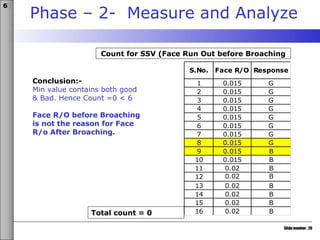

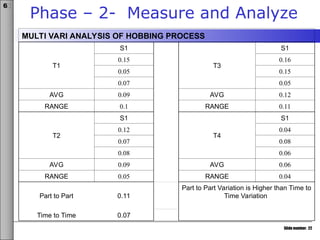

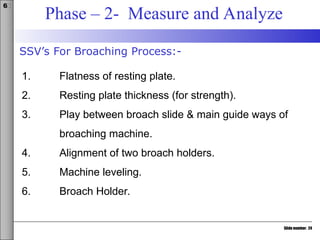

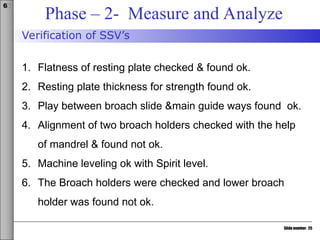

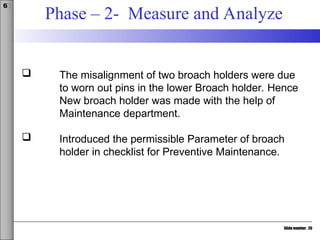

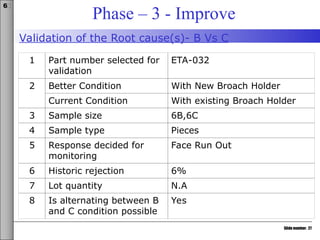

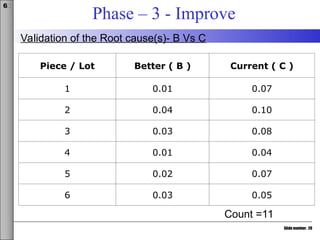

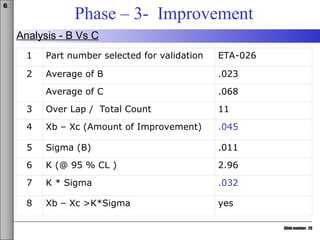

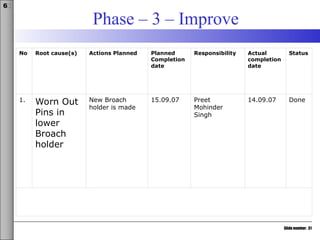

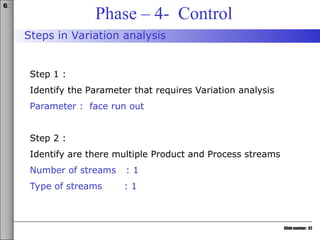

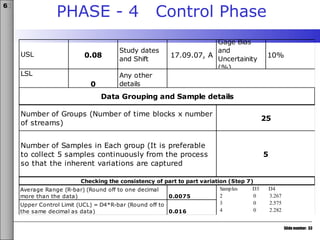

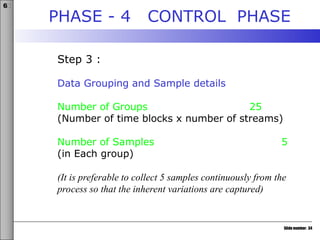

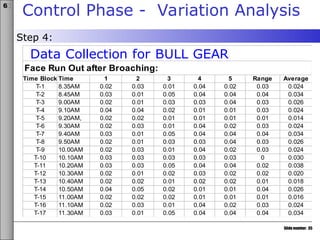

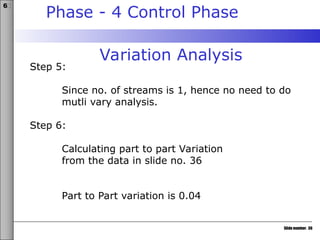

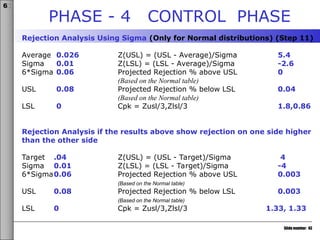

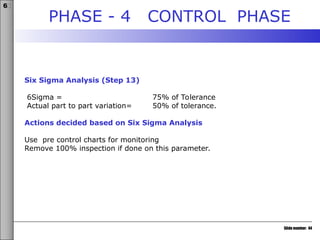

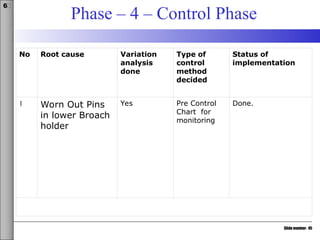

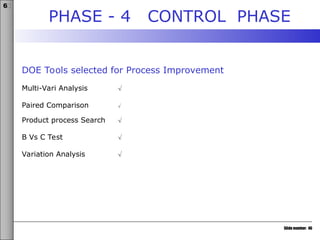

The document outlines a Six Sigma project aimed at reducing rejection rates due to face run-out issues after heat treatment at Duraparts Pvt. Ltd. Specific problems were identified in the heat treatment process, with an average rejection rate of 6% over six months. The project involved multiple phases including defining the problem, analyzing variations, and implementing improvements, resulting in the establishment of new broach holder parameters to enhance quality control.