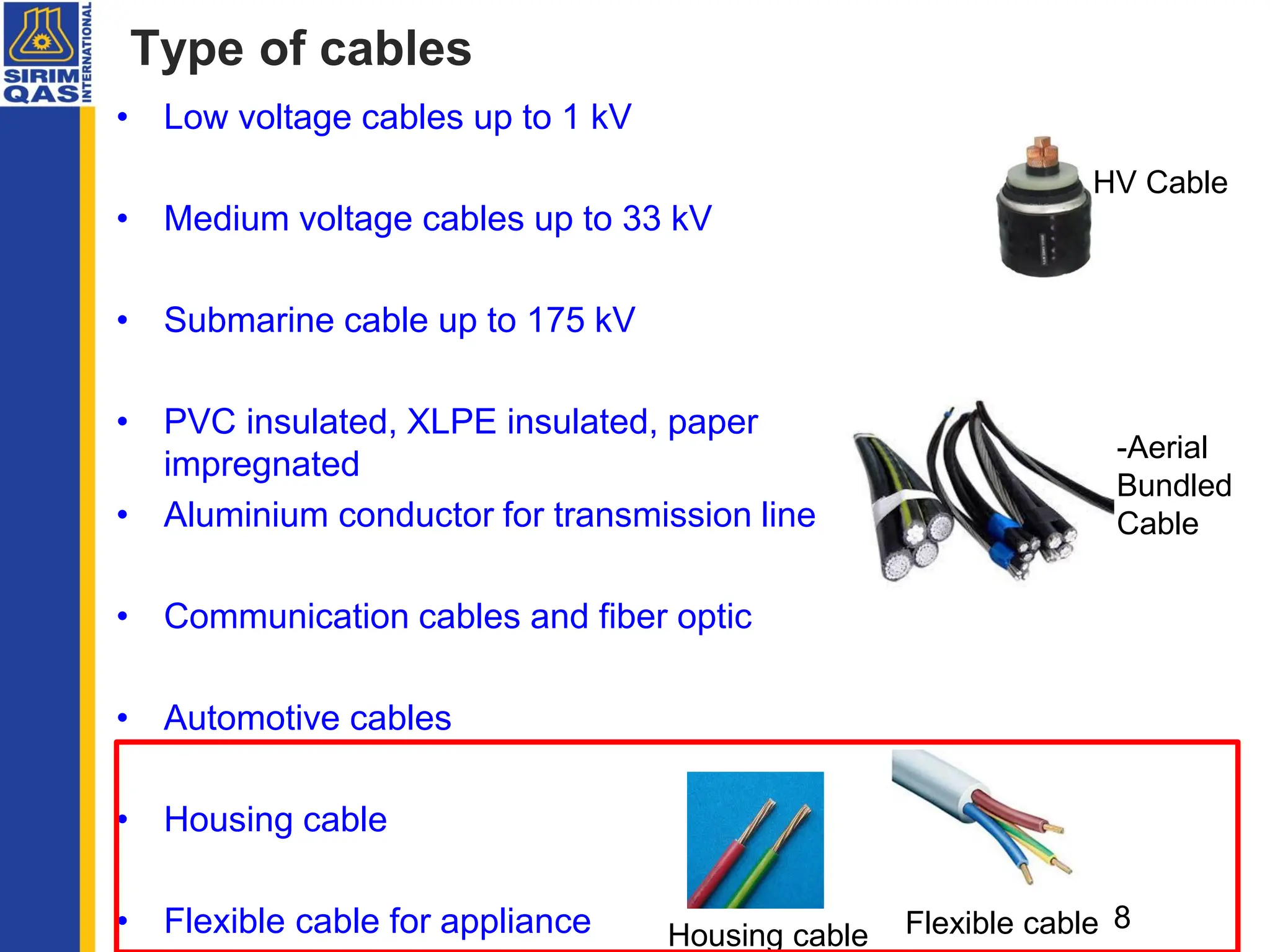

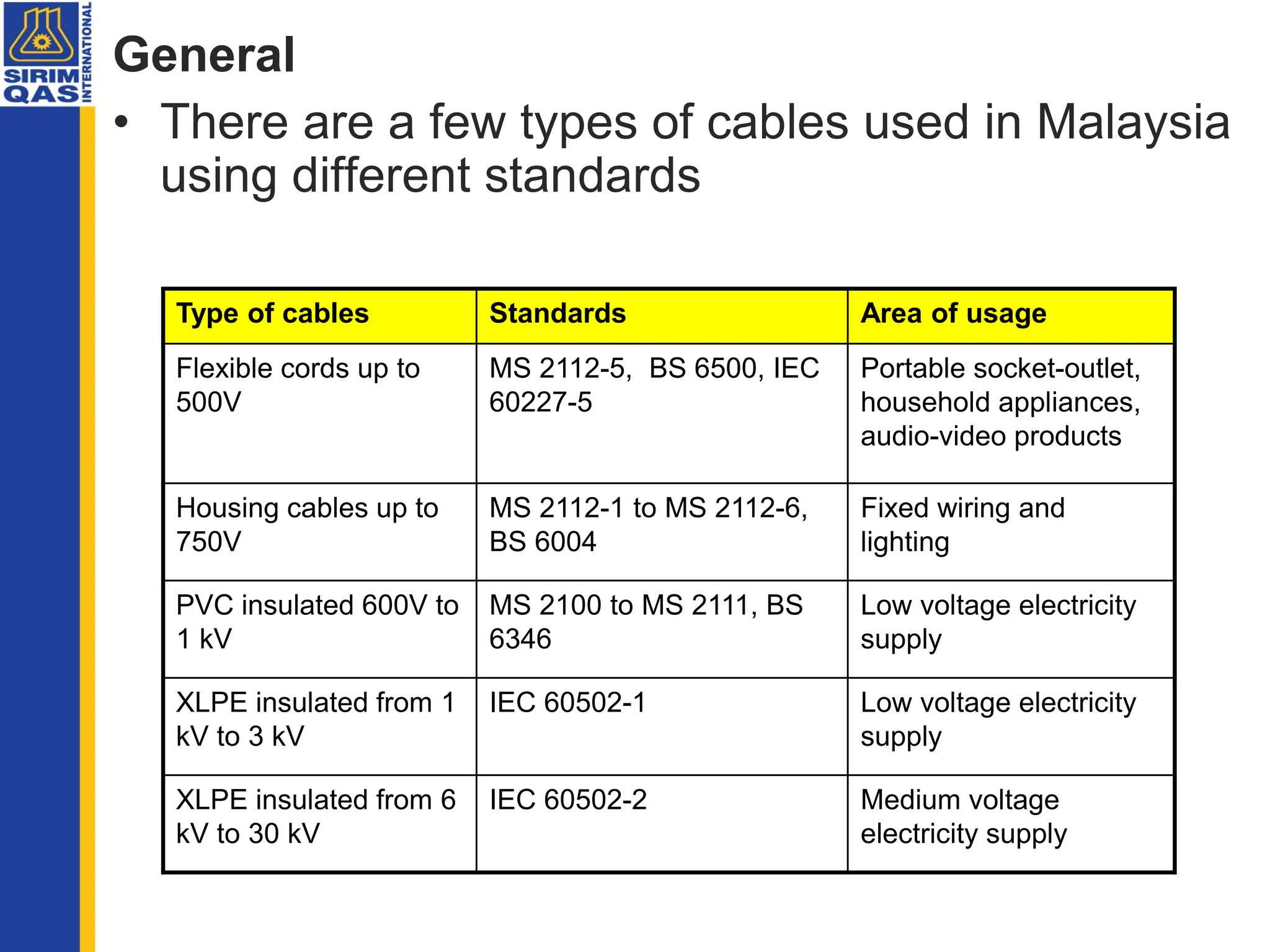

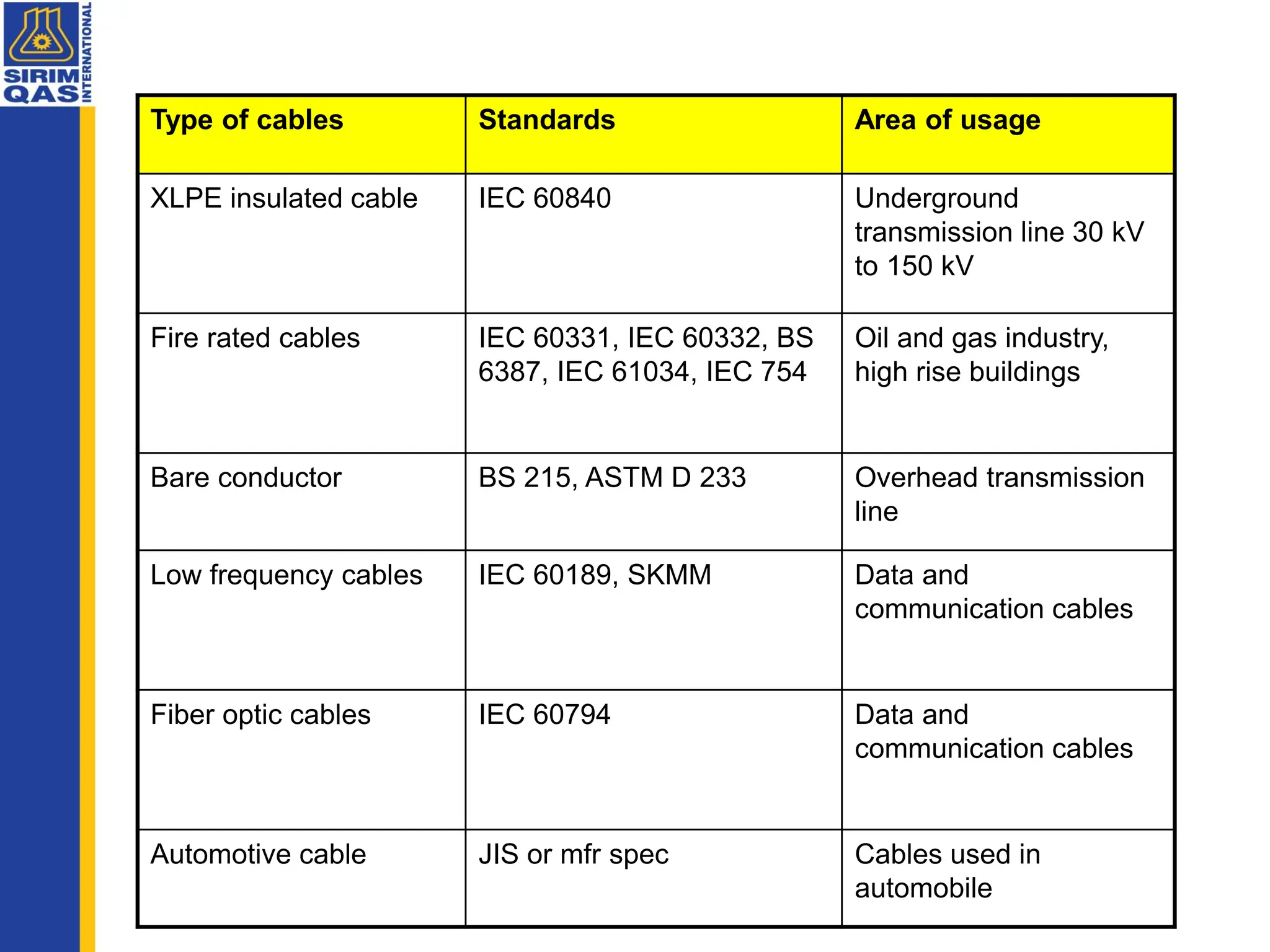

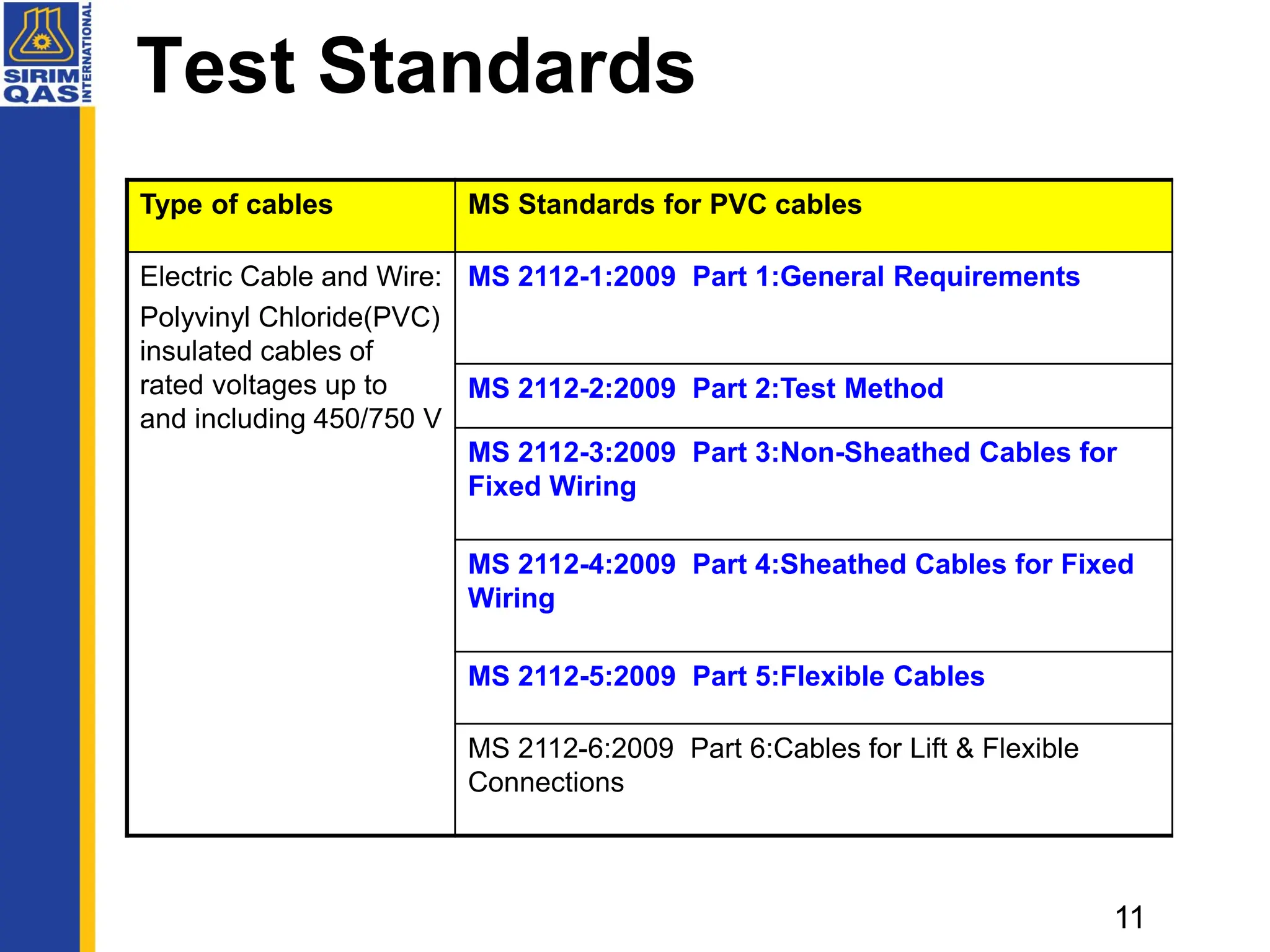

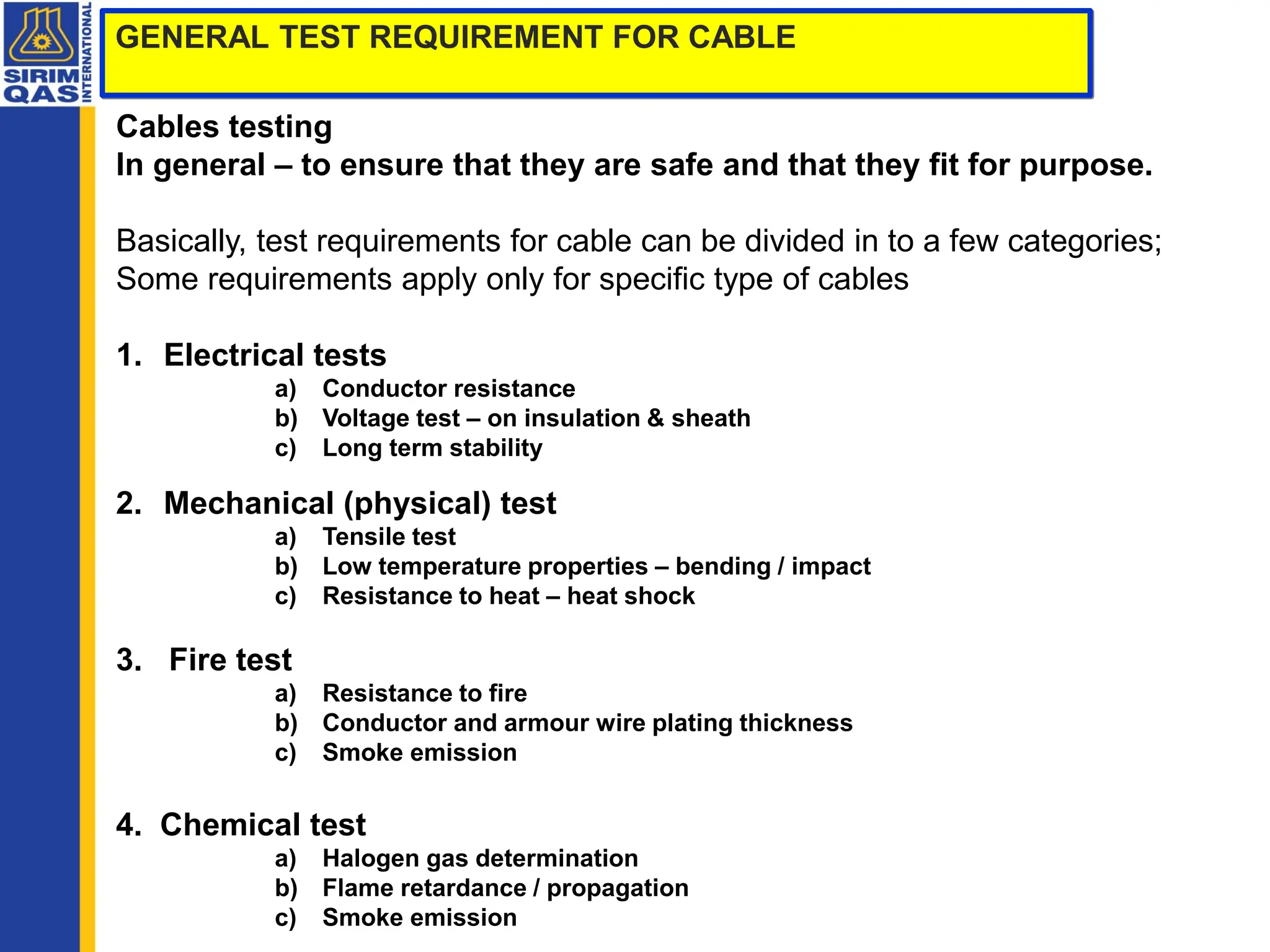

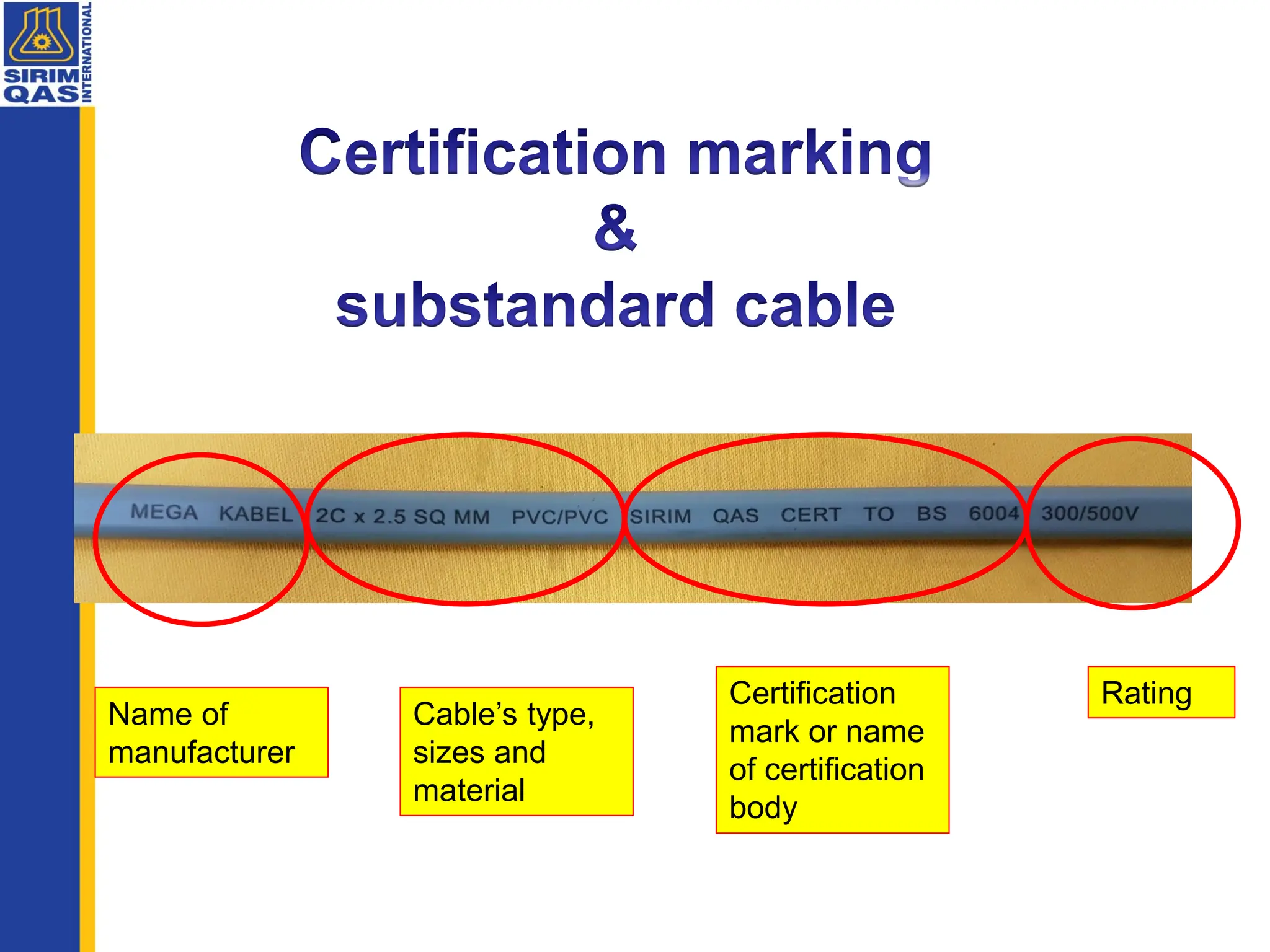

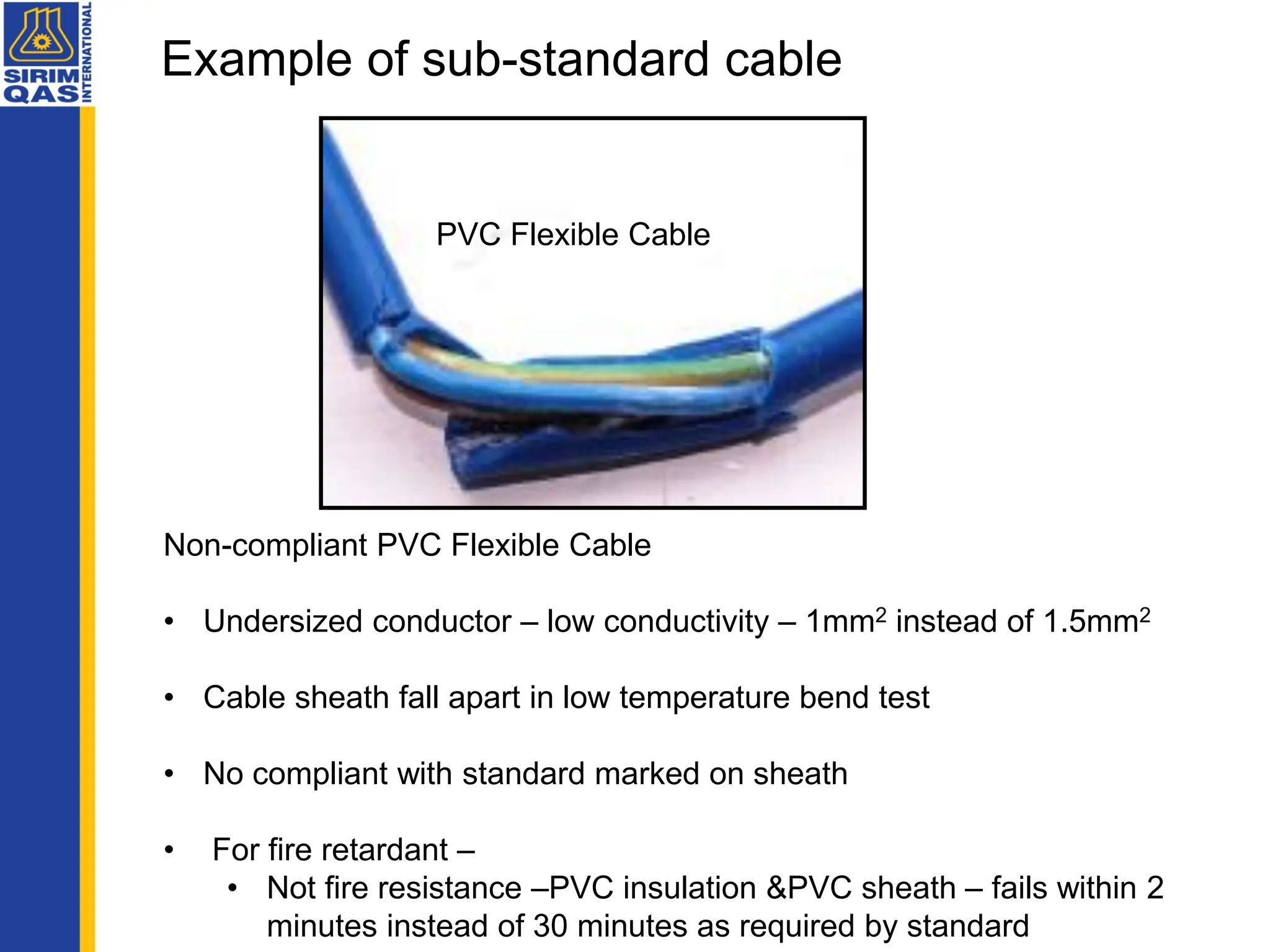

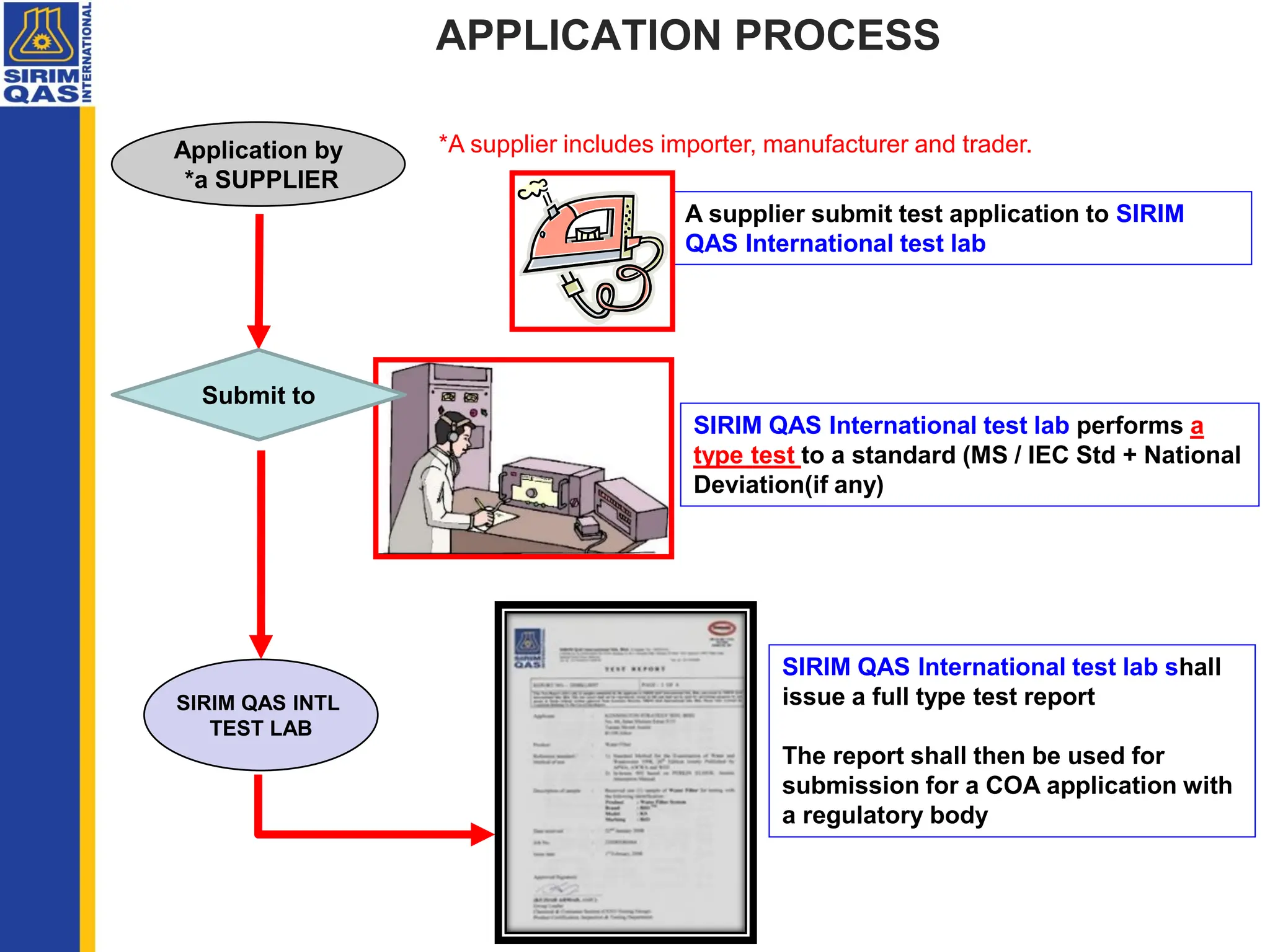

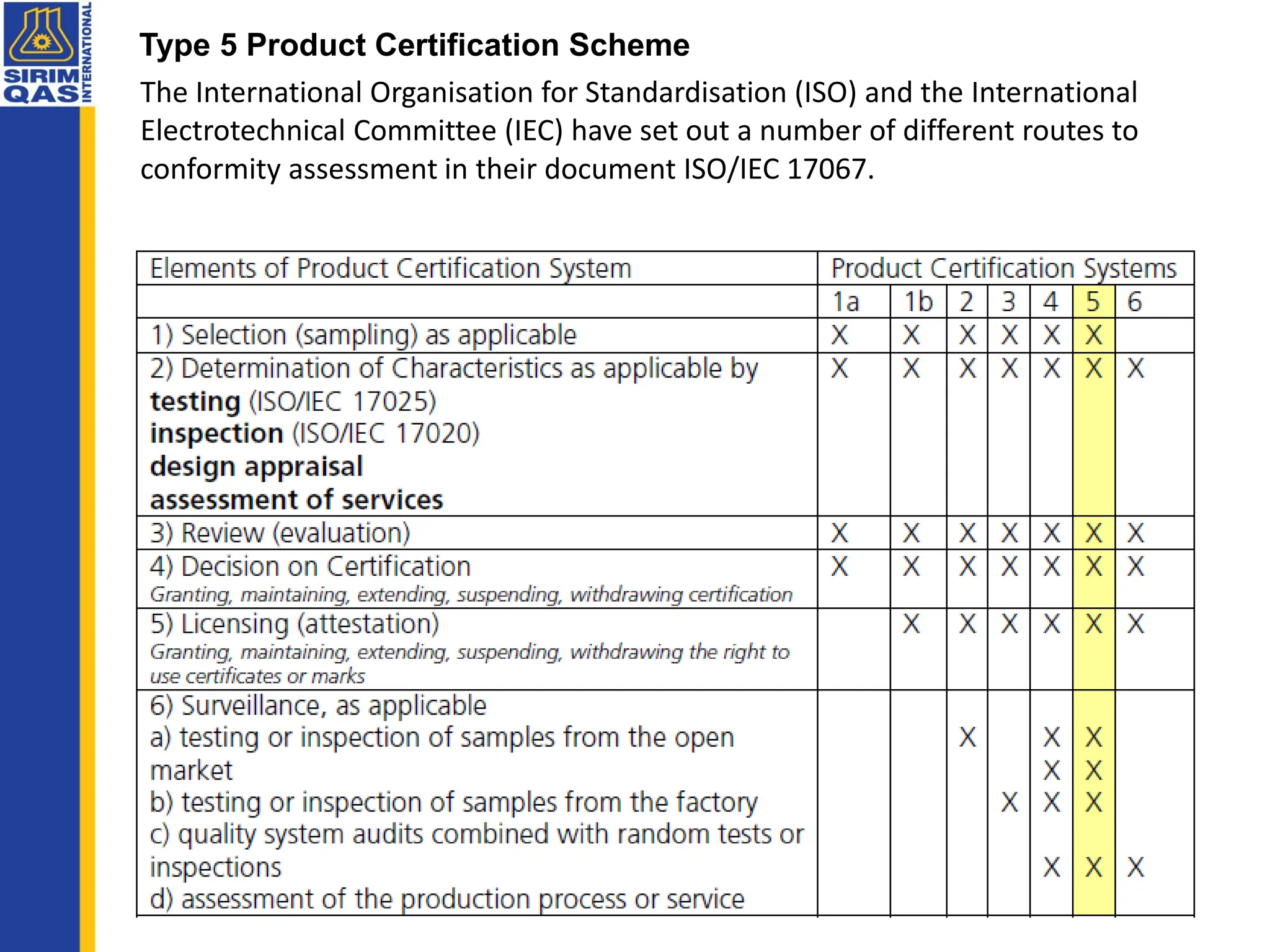

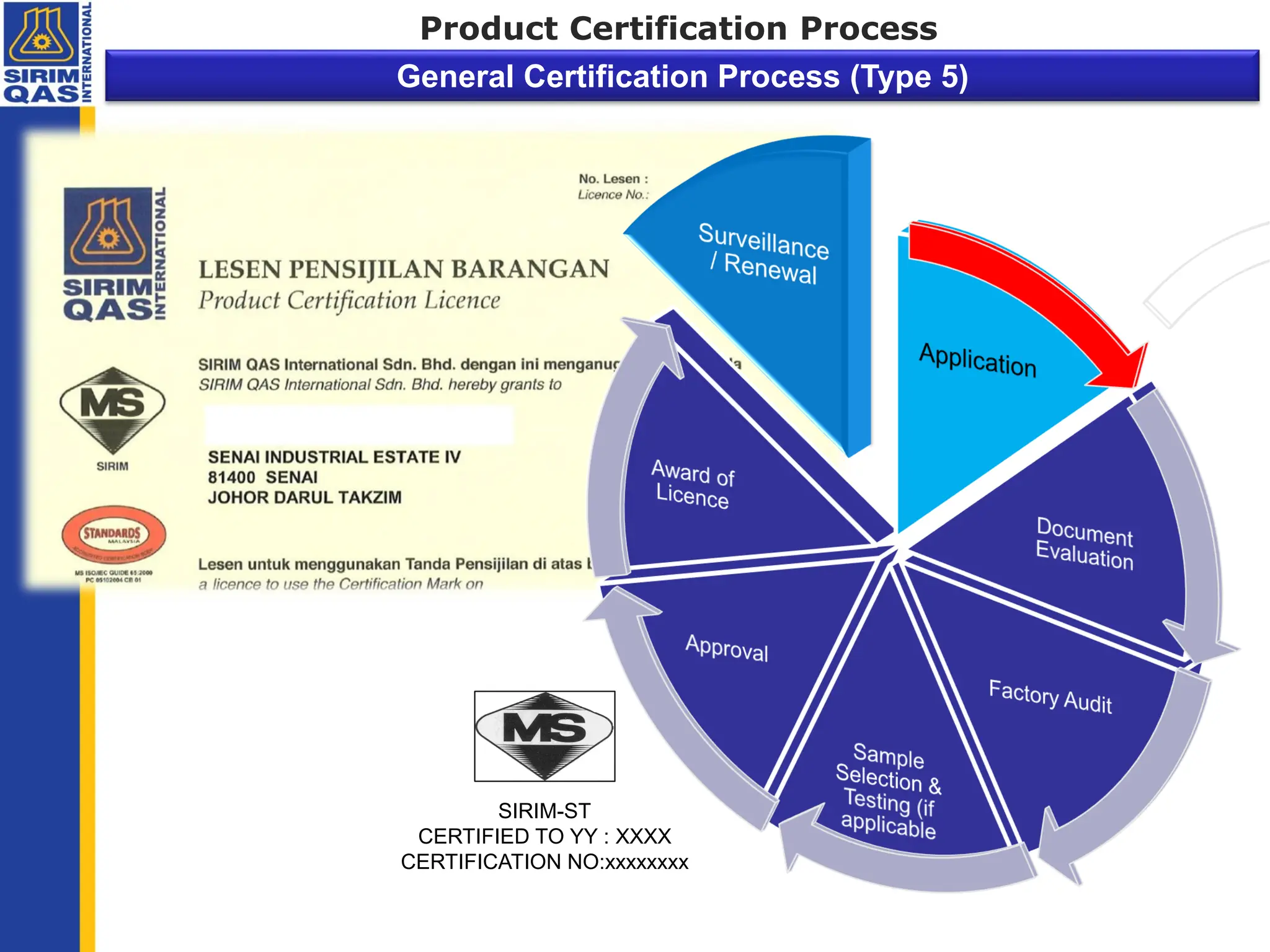

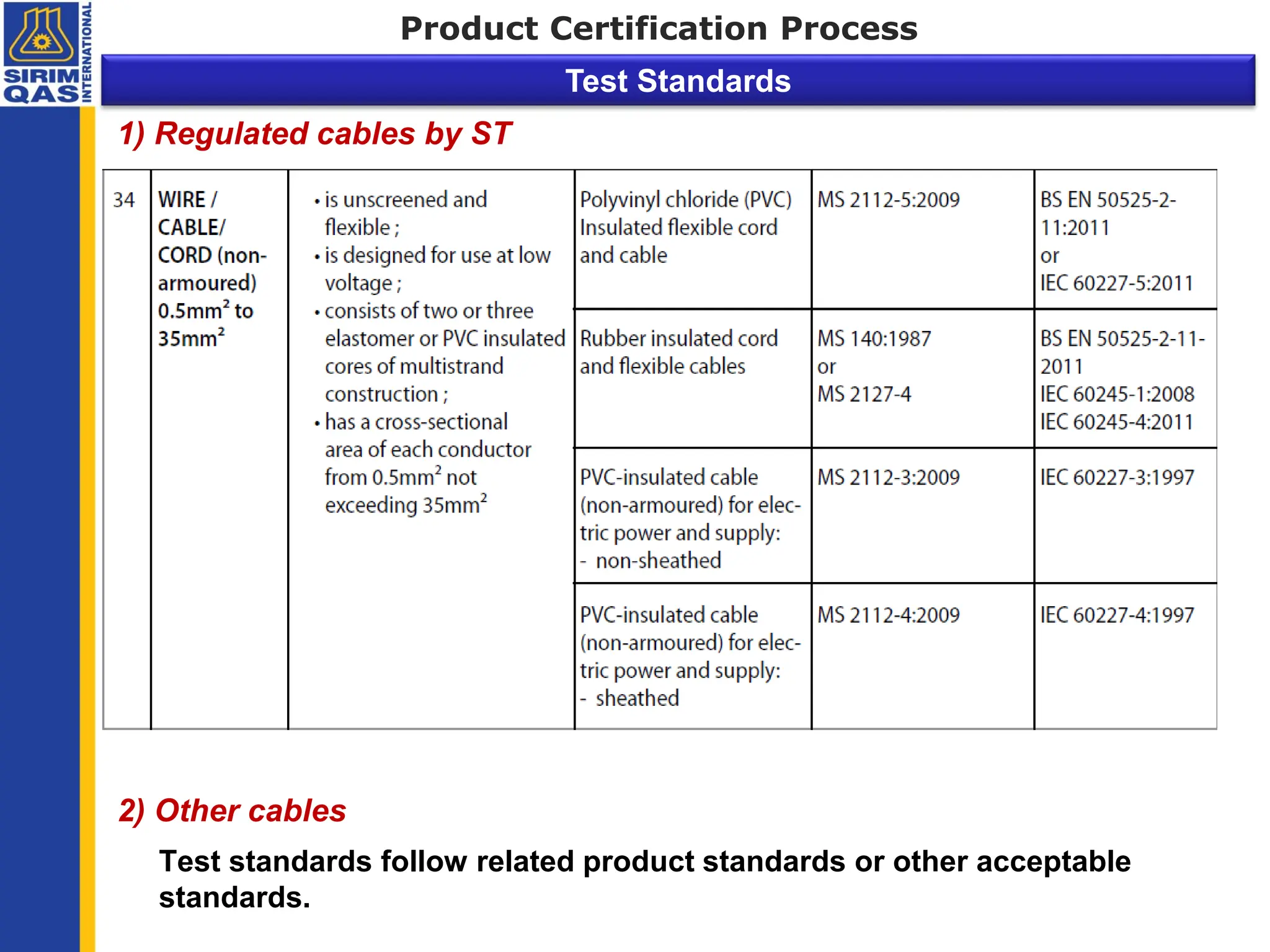

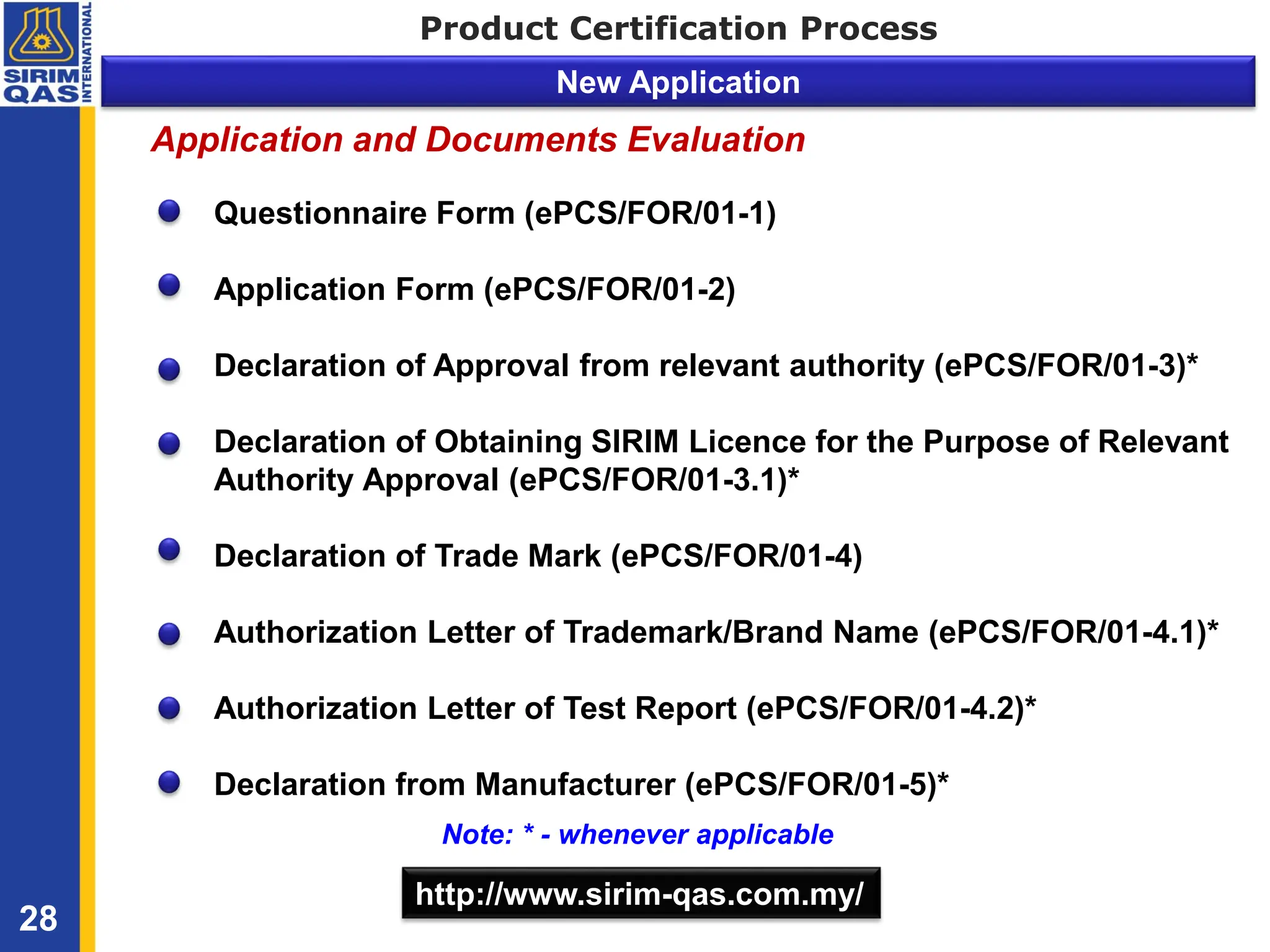

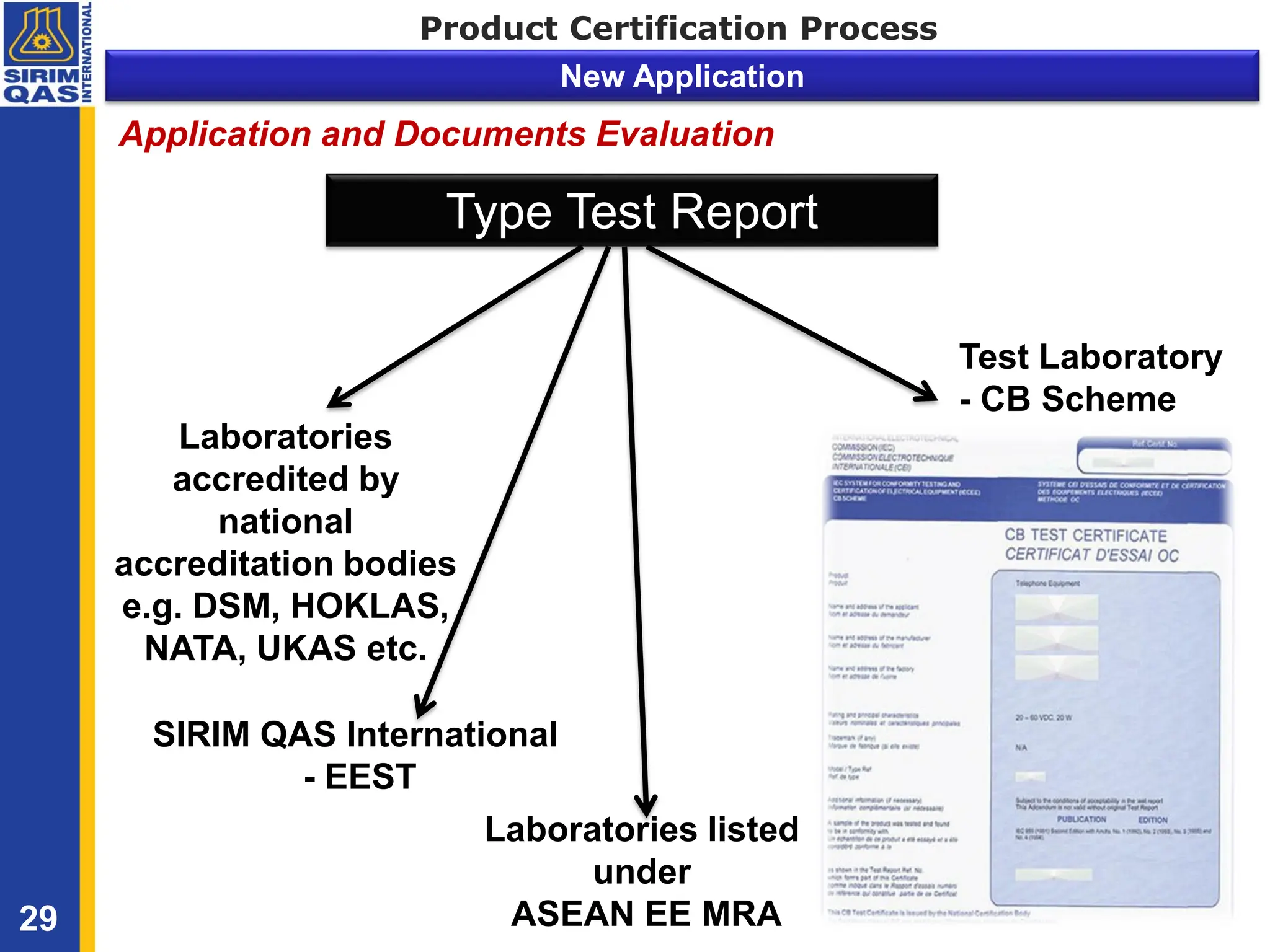

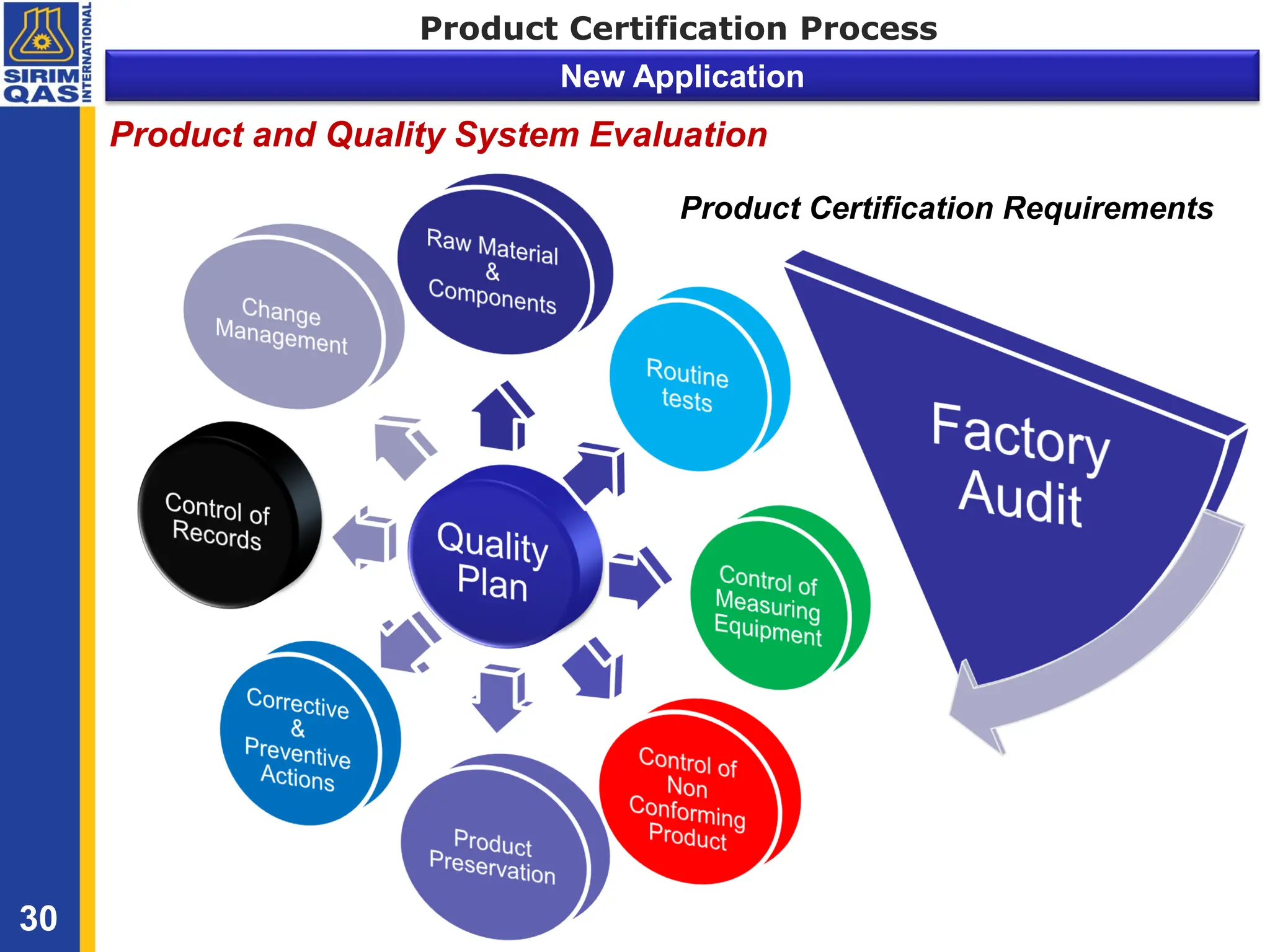

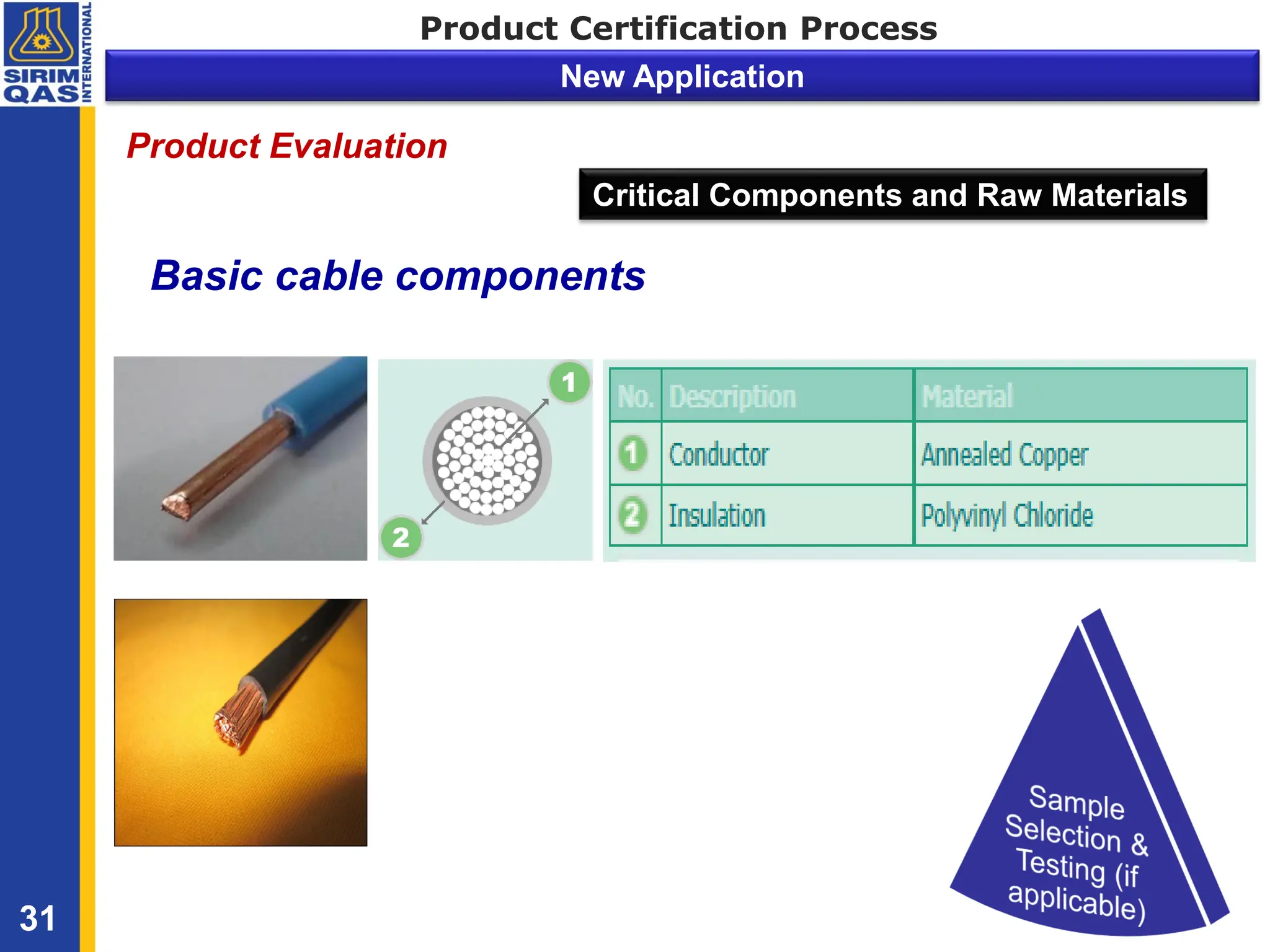

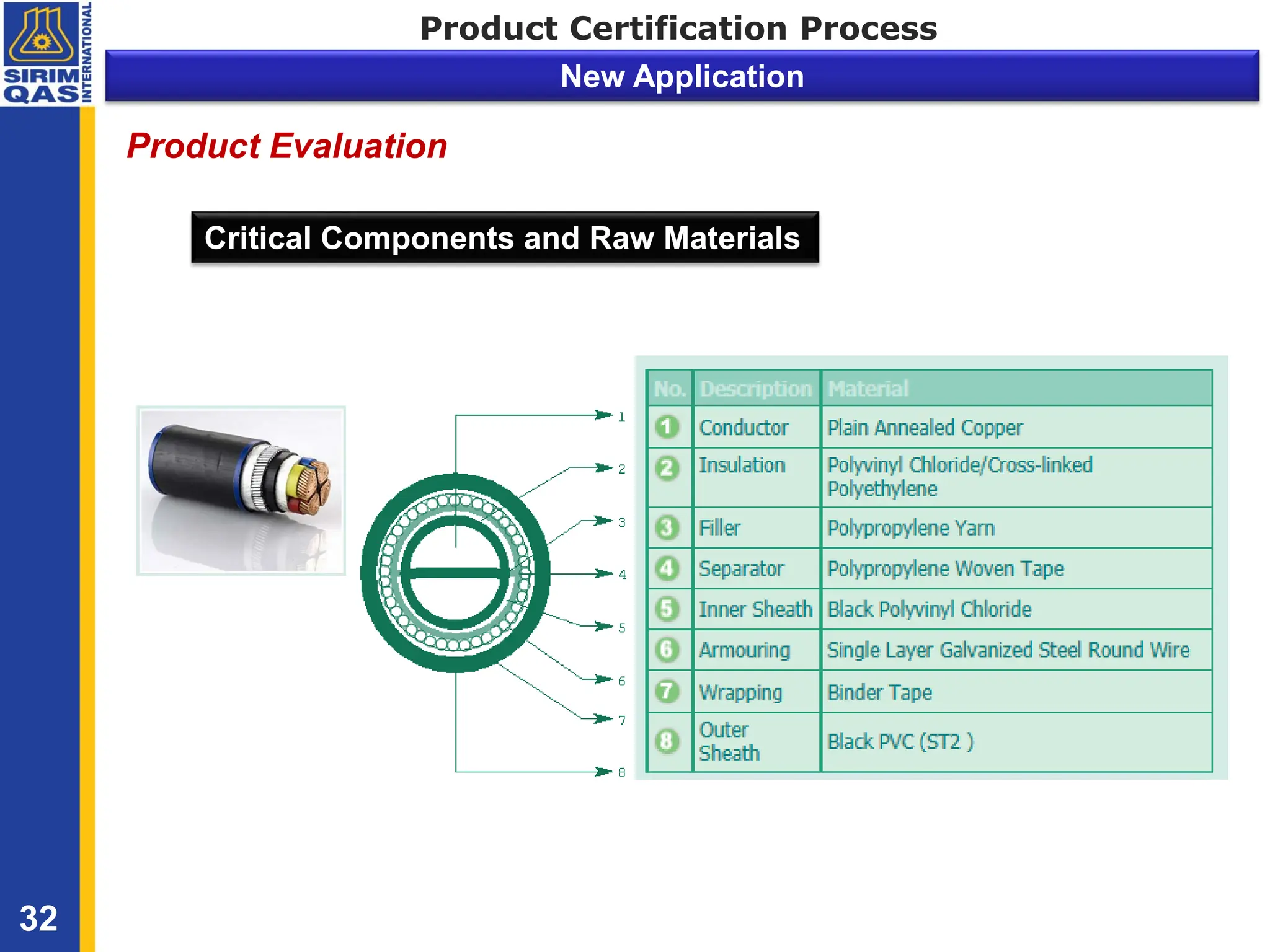

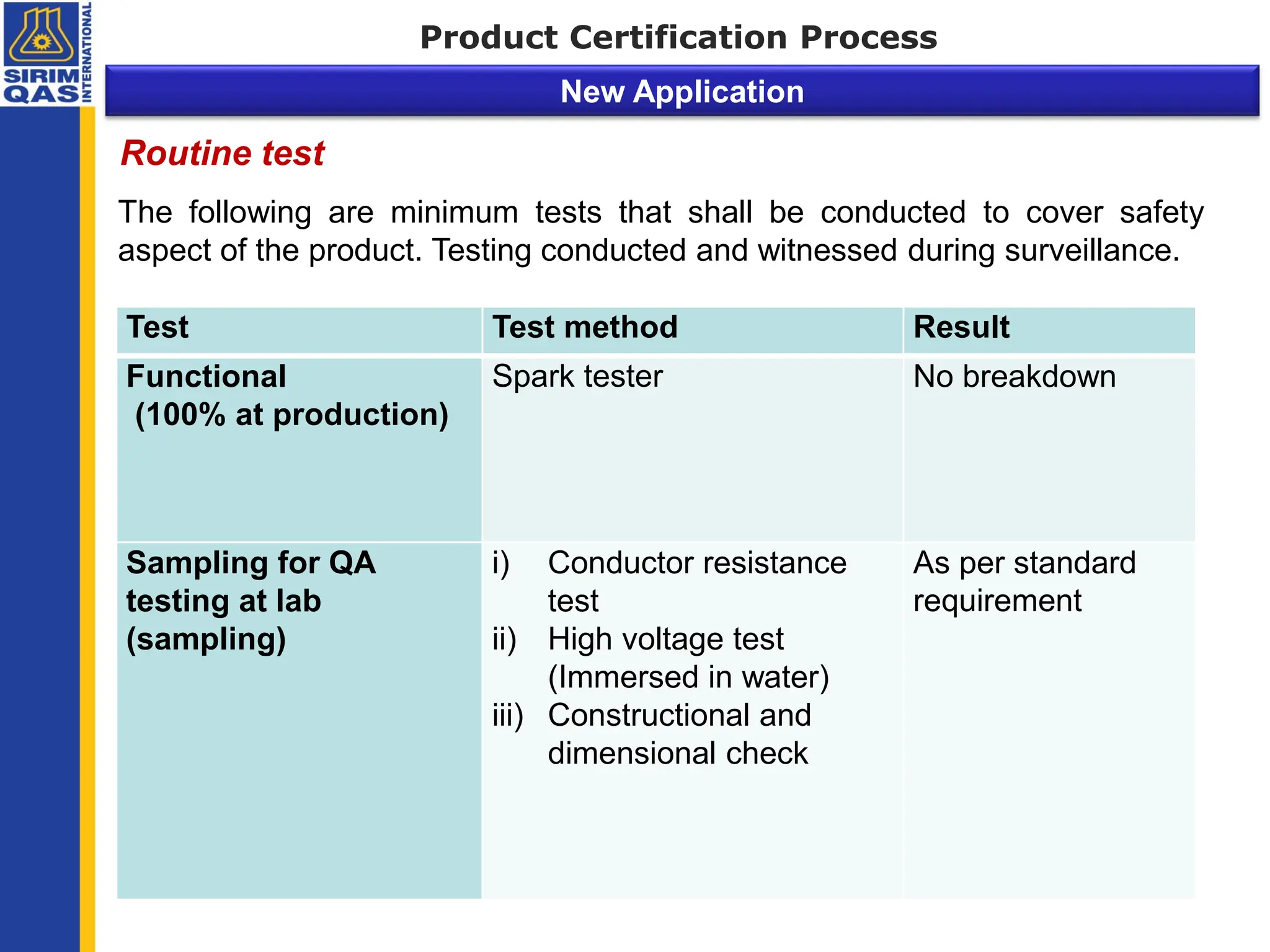

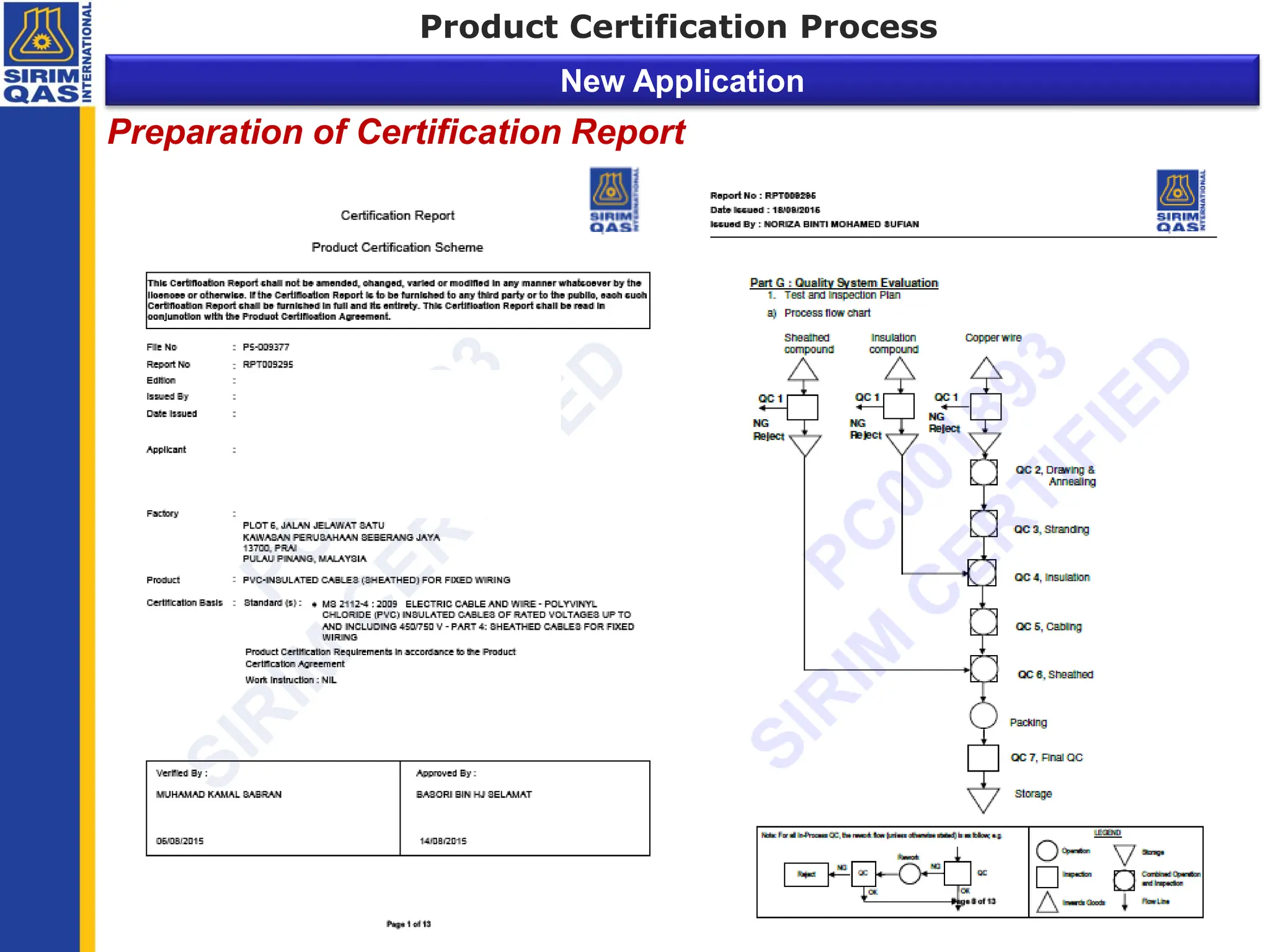

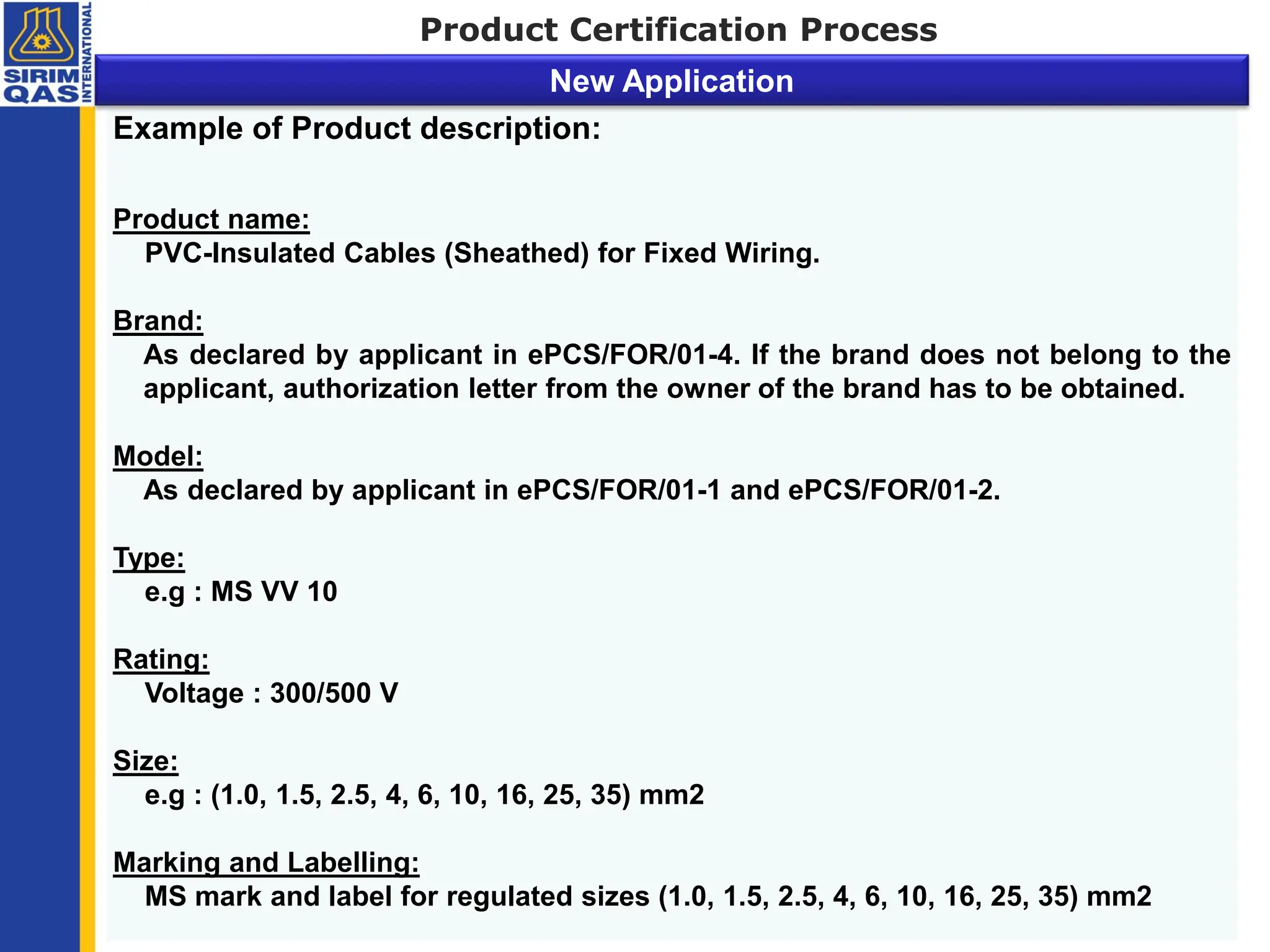

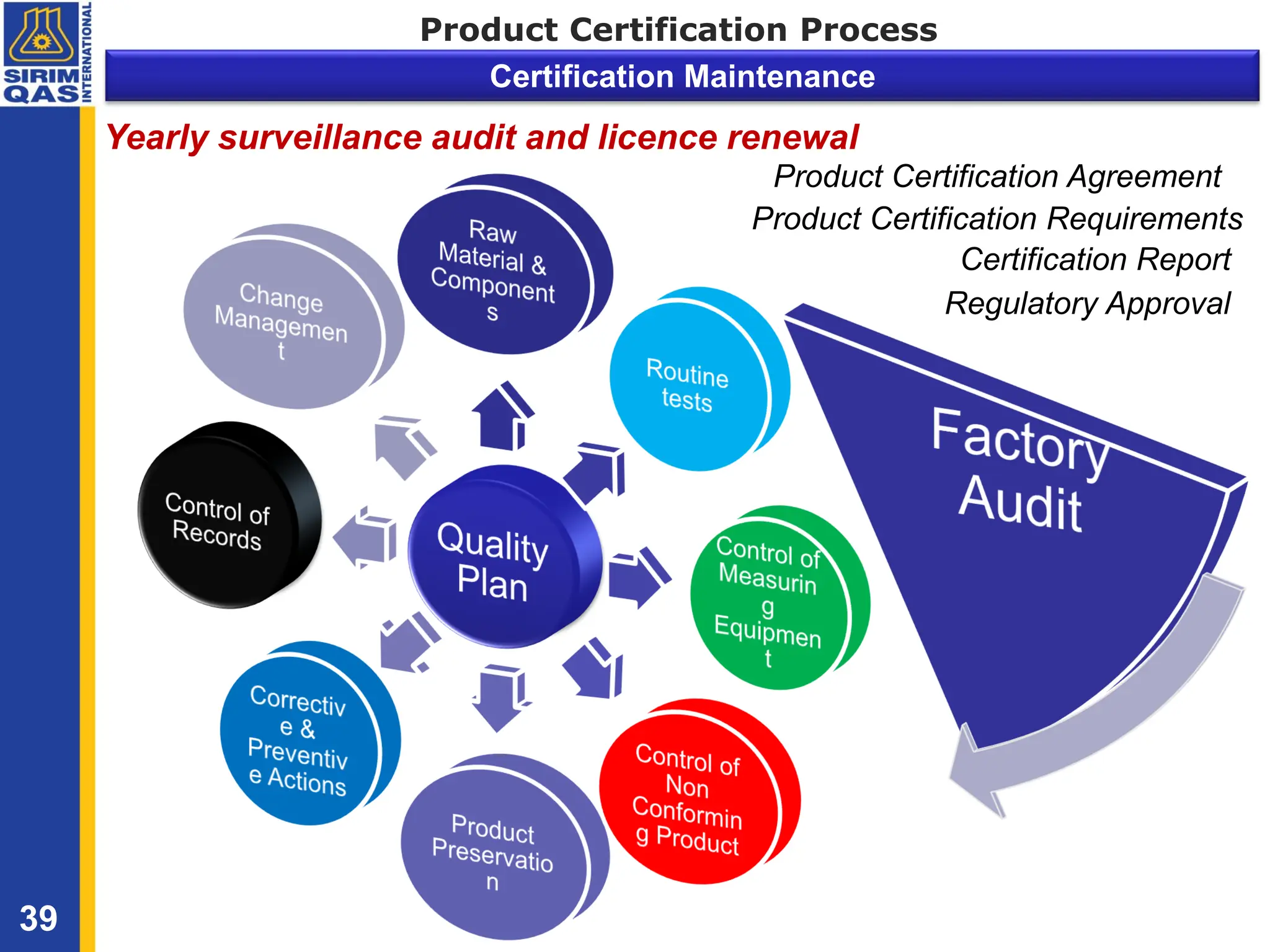

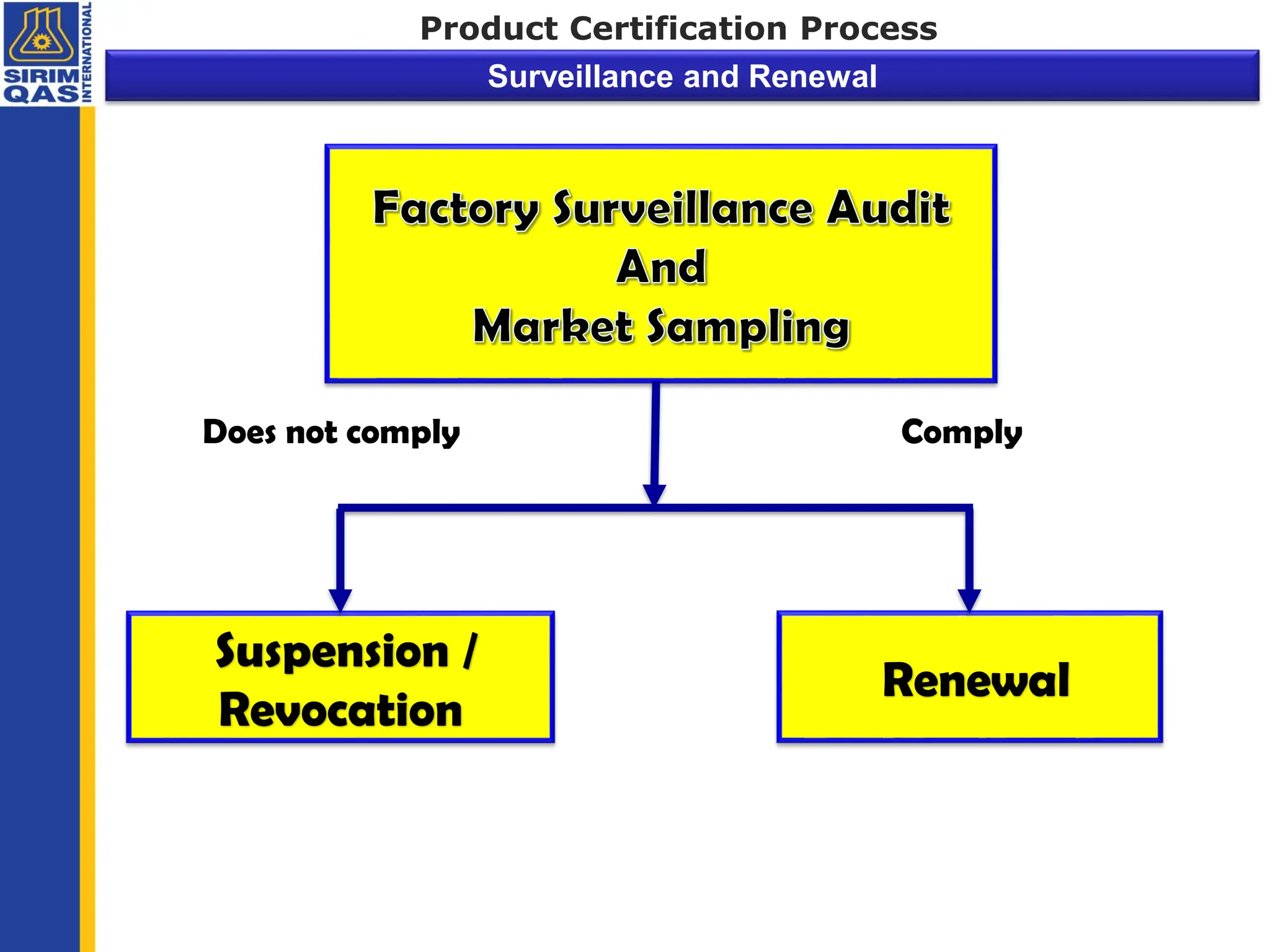

The document discusses electrical cable testing conducted by SIRIM QAS International Sdn Bhd. It provides an overview of their roles and services which include product certification, testing, and inspection. It then describes the different types of cables used in Malaysia and the applicable standards. The document outlines the general test requirements for electrical cables which include electrical, mechanical, fire, and chemical tests. It also discusses issues with substandard cables and SIRIM's role in assisting with compliance testing, certification, and market surveillance. The certification process for electrical cables is summarized in several steps including application, evaluation, testing, and product evaluation.