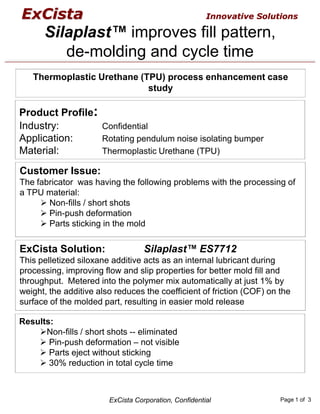

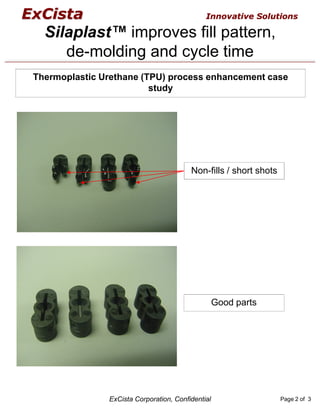

A manufacturer was having issues processing thermoplastic urethane (TPU) including non-fills, pin push deformation, and parts sticking in the mold. ExCista's solution of adding 1% of their Silaplast ES7712 pelletized siloxane additive improved the material flow and reduced the coefficient of friction, eliminating the non-fills and pin push deformation. It also allowed for easier mold release and a 30% reduction in total cycle time.