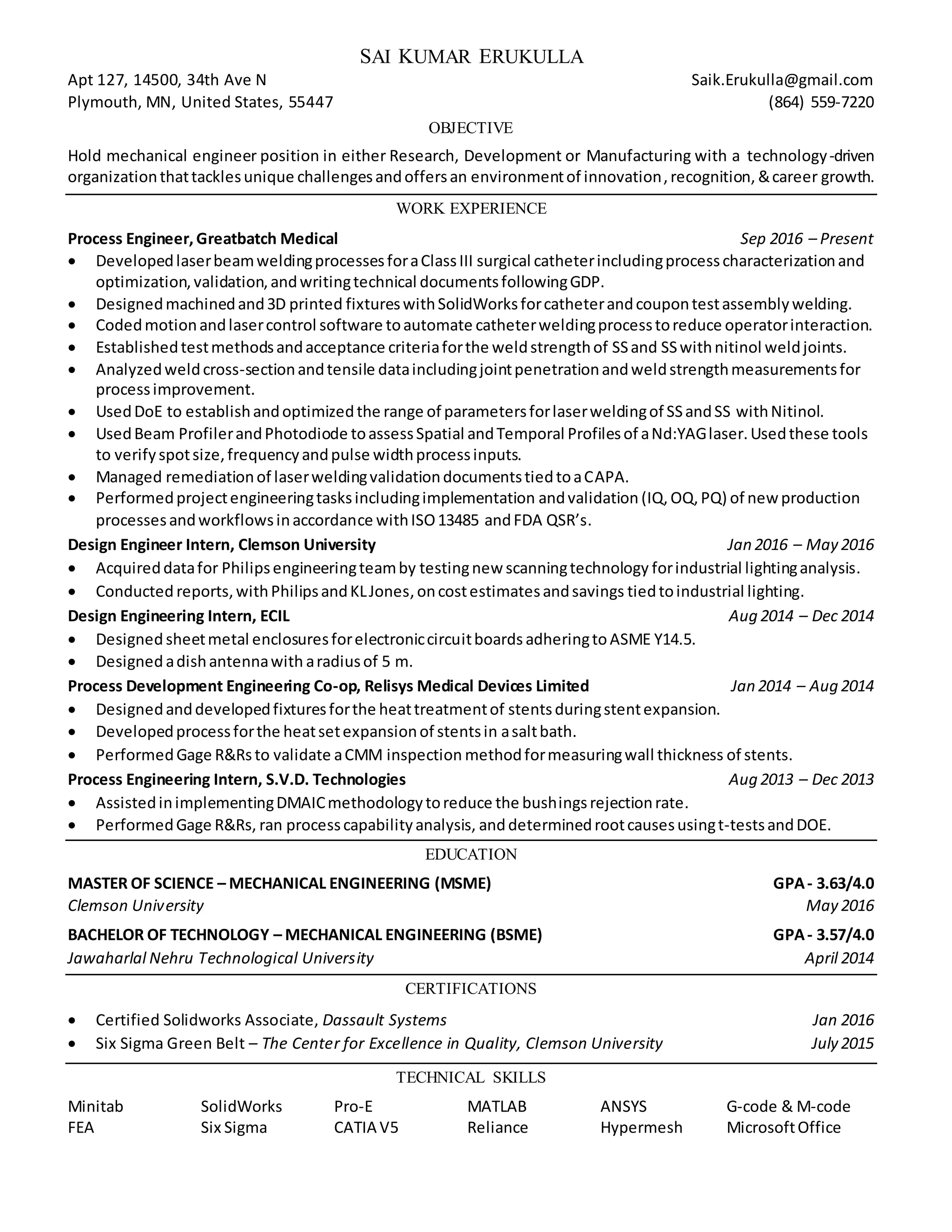

Sai Kumar Erukulla is a mechanical engineer seeking a position in research, development, or manufacturing. He has over 4 years of experience developing and optimizing manufacturing processes, including laser beam welding of surgical catheters. At his current role, he designed fixtures, wrote software to automate welding, and validated new production processes. Previously, he interned in design engineering, developing stents and analyzing industrial lighting.