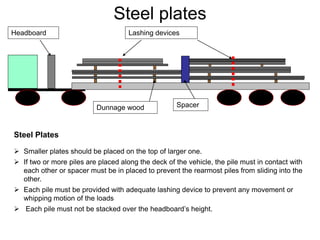

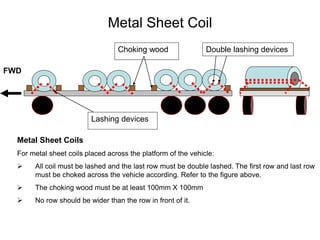

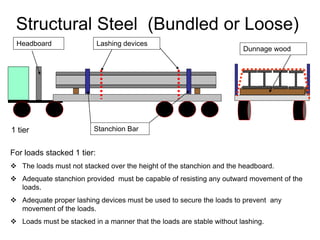

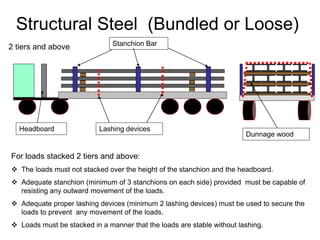

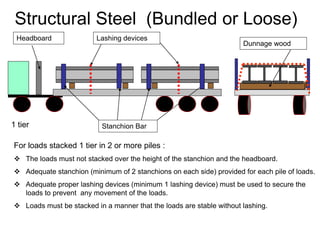

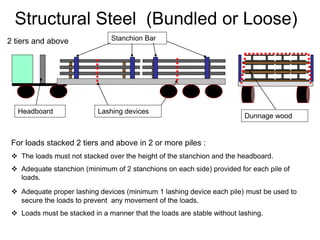

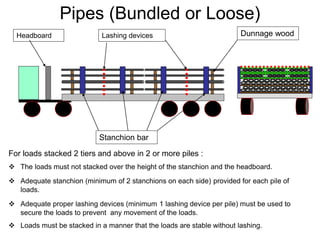

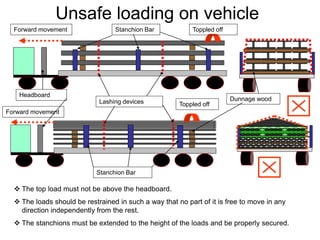

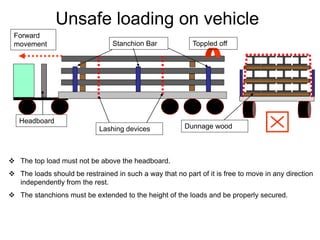

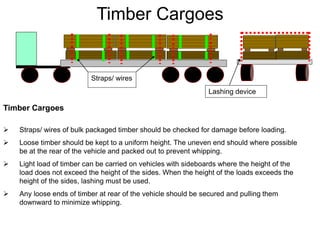

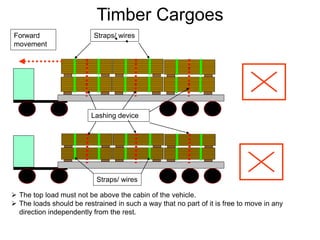

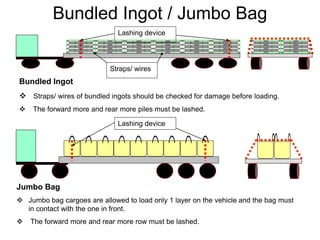

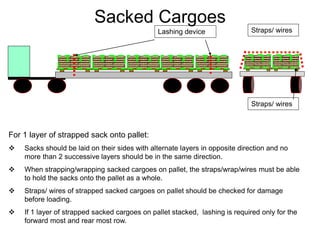

The document provides guidelines for securing various types of cargo on vehicles. It discusses requirements for headboards, stanchions, lashing, stacking and securing loads such as steel plates, metal coils, structural steel, pipes, pallets, drums, sacks, tires and more. Proper load securement is important to prevent cargo from shifting or falling during transport which could make the vehicle unstable or result in an accident.