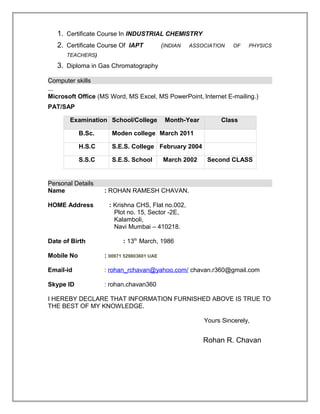

Rohan Ramesh Chavan is seeking a position in production, quality assurance, quality control, or plant operations. He has over 5 years of experience in these areas for companies in India and the UAE. His skills include production planning, materials management, quality management, and people management. He has experience developing new products, establishing testing facilities, and ensuring compliance with ISO standards.