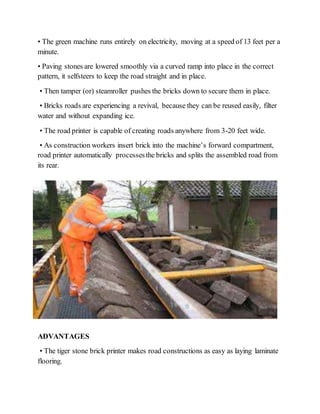

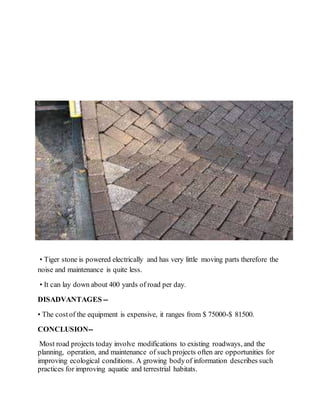

The document discusses the Tiger Stone road printer, a machine invented by a Dutch company that can pave an entire street at once. It works by using gravity to lay bricks in the correct pattern as the machine rolls backwards. Operators stand on the machine and fill its hopper with loose bricks which are then smoothed into place. The road printer makes road construction as easy as laying flooring and can lay about 400 yards of road per day, though the machine is expensive, costing between $75,000-$81,500.