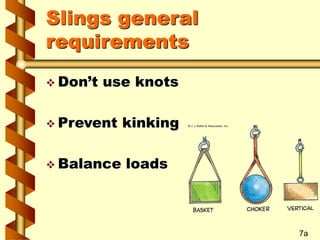

The document outlines safety standards and inspection requirements for rigging equipment used in material handling, emphasizing safe working loads and the necessity for regular inspections. It details various types of rigging equipment such as alloy steel chains, slings, and synthetic webbing, along with guidelines for their use and maintenance. Key points include ensuring equipment is marked with rated capacities, removing defective items, and adhering to the manufacturer's recommendations.