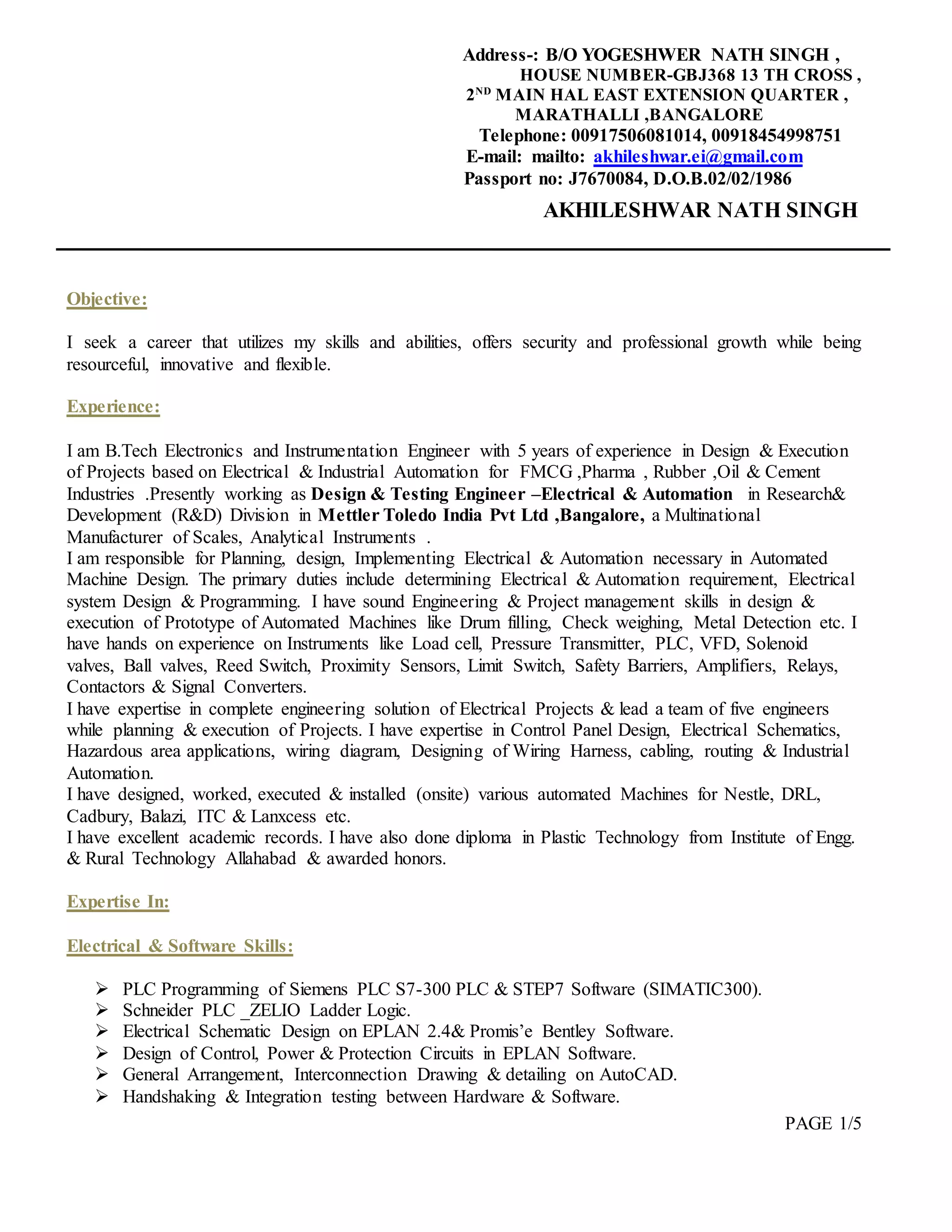

Akhileshwar Nath Singh is seeking a career that utilizes his 5 years of experience in electrical and industrial automation projects. He currently works as a Design & Testing Engineer at Mettler Toledo India Pvt Ltd, where he is responsible for planning, designing, and implementing electrical systems and automation for automated machinery. He has expertise in PLC programming, electrical schematic design, control panel design, hazardous area applications, and industrial automation. He has worked on projects for clients like Nestle, DRL, Cadbury, Lanxess, ITC, and others.