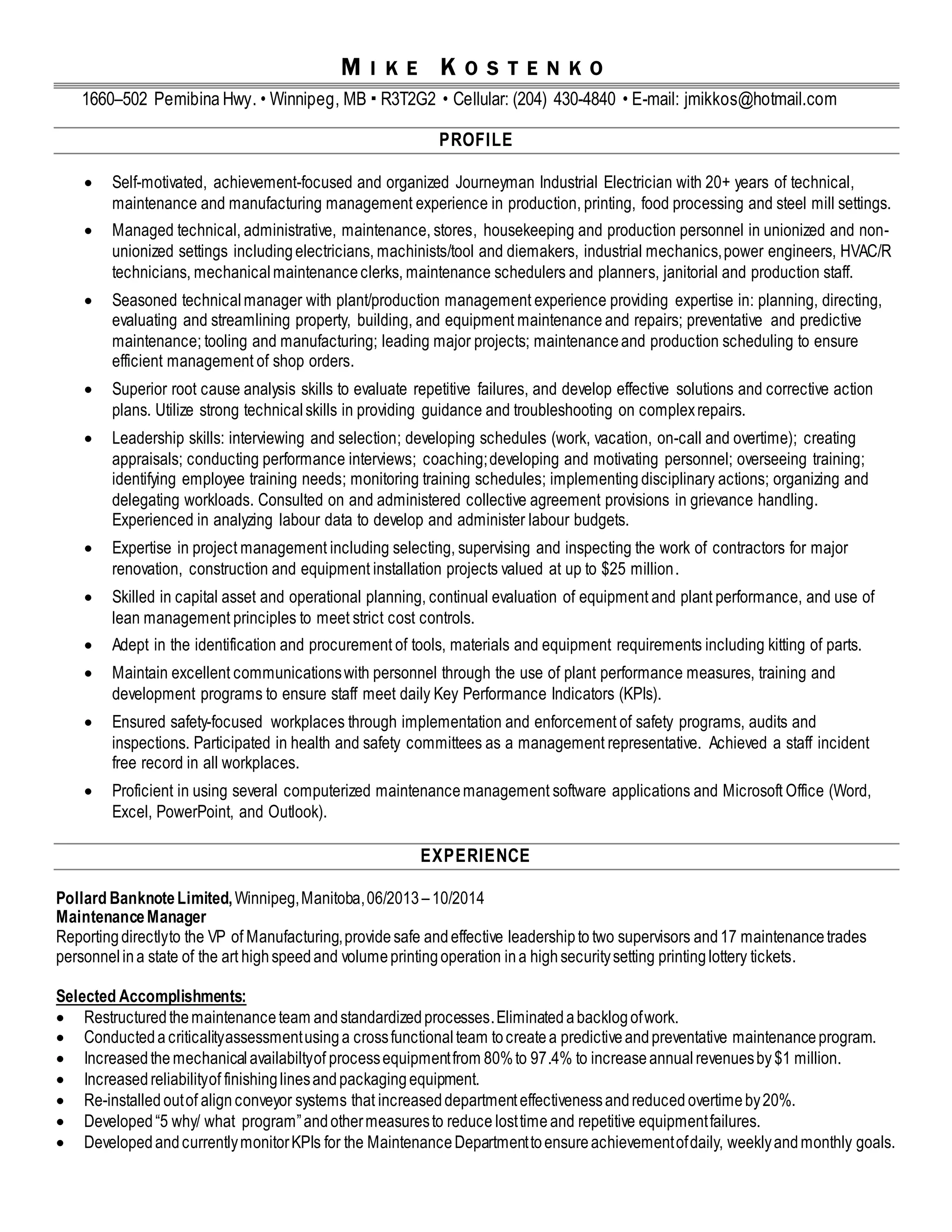

The document is a resume for Mike Kostenko, an experienced Journeyman Industrial Electrician and maintenance/facilities manager with over 20 years of experience managing maintenance operations and personnel in various manufacturing settings. It outlines his technical skills and experience planning and directing maintenance activities, developing budgets, and ensuring safety and regulatory compliance. Key accomplishments include improving equipment uptime and reliability, reducing costs, developing training programs, and transforming workplaces to be injury-free.