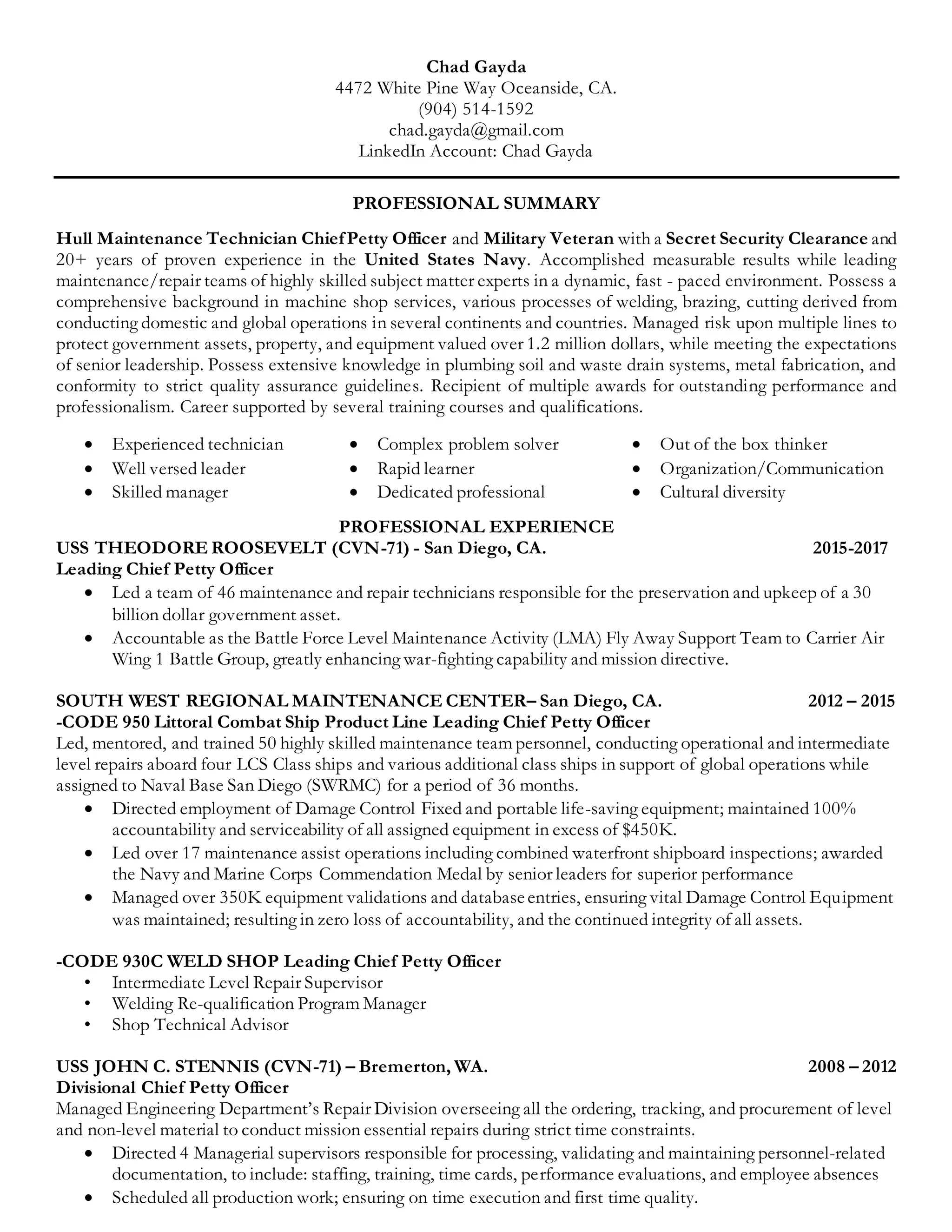

This document is a resume for Chad Gayda, a Hull Maintenance Technician Chief Petty Officer and military veteran with over 20 years of experience in the United States Navy. He has led maintenance and repair teams on aircraft carriers and other naval vessels. Gayda is skilled in various processes including welding, brazing, and cutting. He has a background in machine shop services and experience conducting operations globally. Gayda seeks a position applying his leadership, management, and maintenance experience.