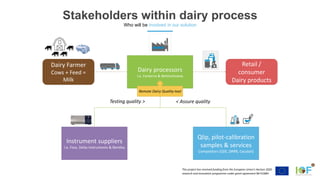

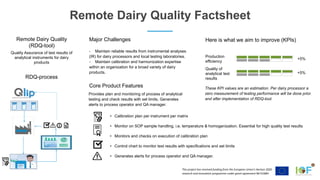

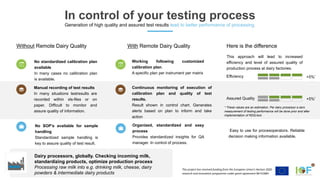

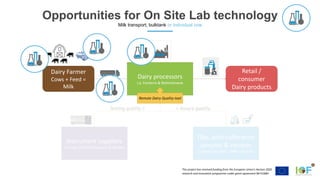

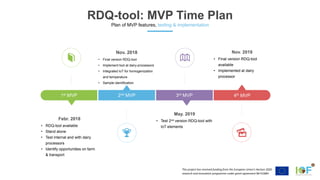

This document discusses the Remote Dairy Quality project which received funding from the European Union's Horizon 2020 program. The project aims to develop a tool called the Remote Dairy Quality tool (RDQ tool) to help dairy processors and local testing laboratories maintain reliable analytical test results for dairy products. The RDQ tool will provide standardized calibration plans, monitor sample handling procedures, check test results against specifications, and generate alerts. This is expected to increase the efficiency and quality assurance of analytical testing processes and results. A timeline is provided for developing minimum viable products of the RDQ tool between 2018-2019 with testing at dairy processors and integrating IoT elements.