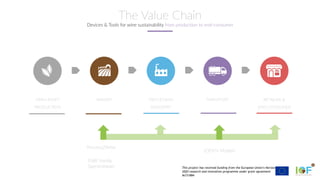

This document describes several IoT tools being developed for sustainable wine production, quality management, and shipping monitoring. The tools include sensors and software to monitor vineyards, wineries, and shipments. Sensors collect data on production factors like water and pesticide use in vineyards. Spectrometers and software analyze wine composition. Data loggers track temperature during shipping to identify quality issues. The tools aim to reduce costs, improve sustainability, and help resolve disputes through remote monitoring and data analysis.