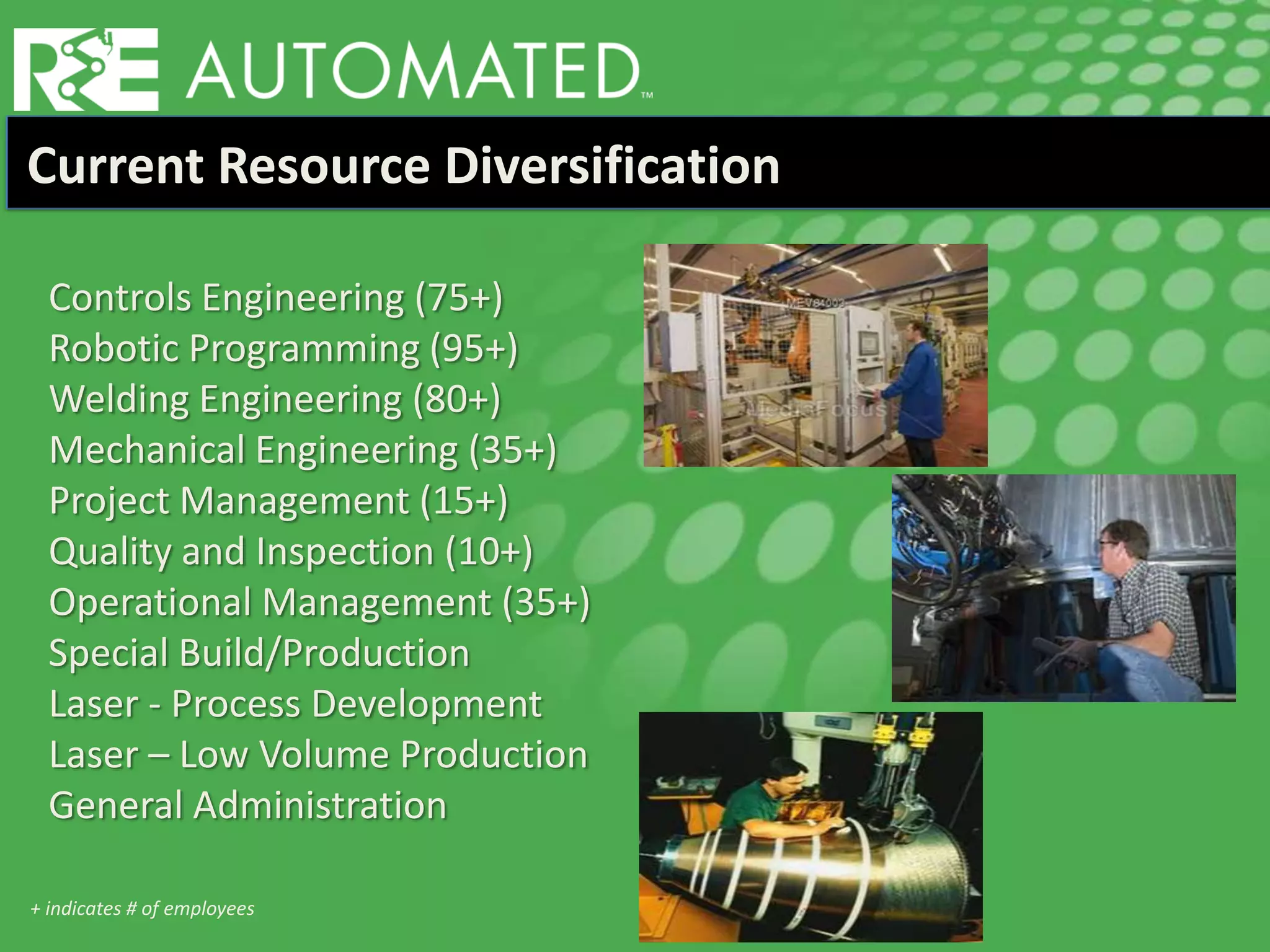

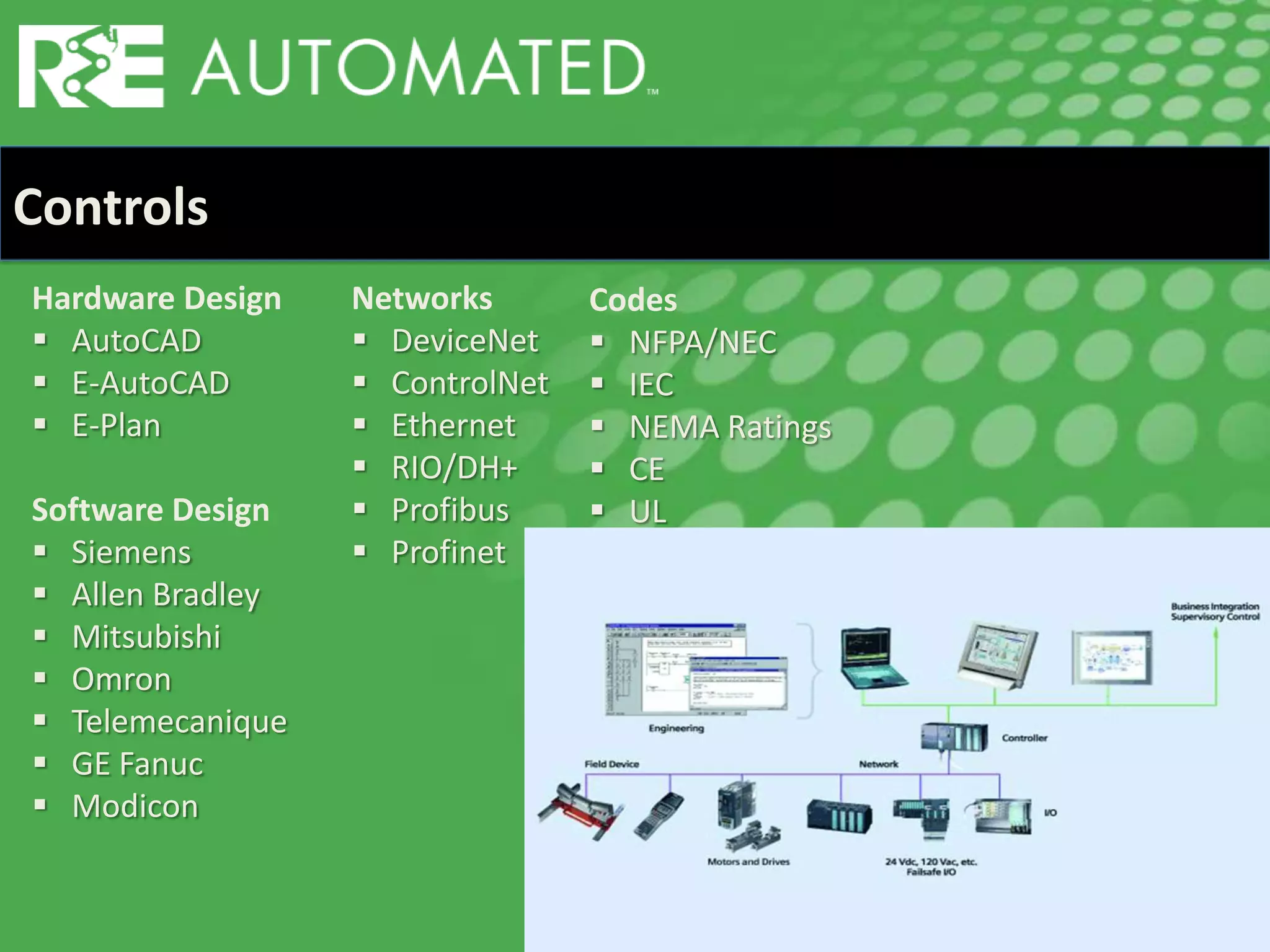

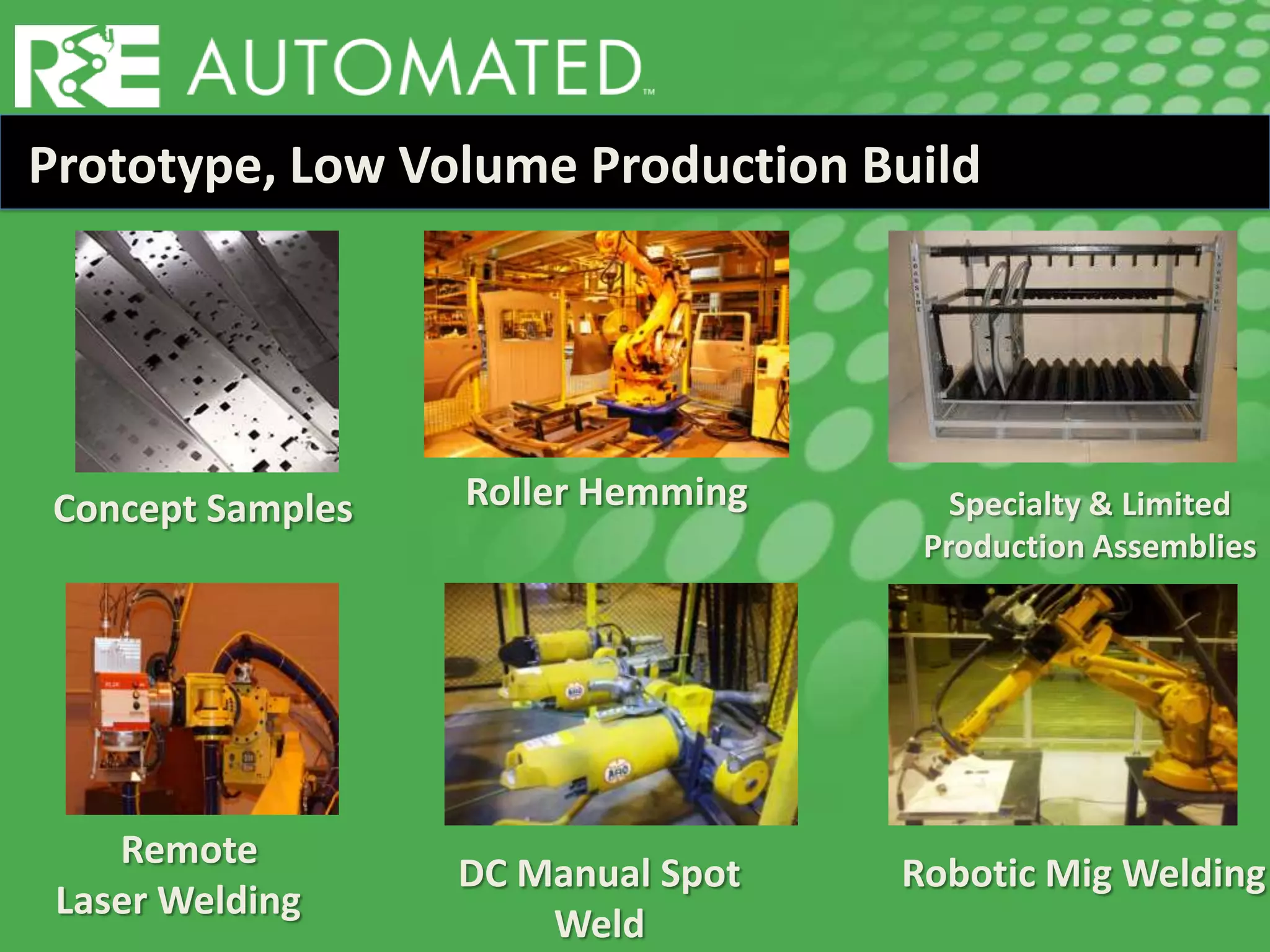

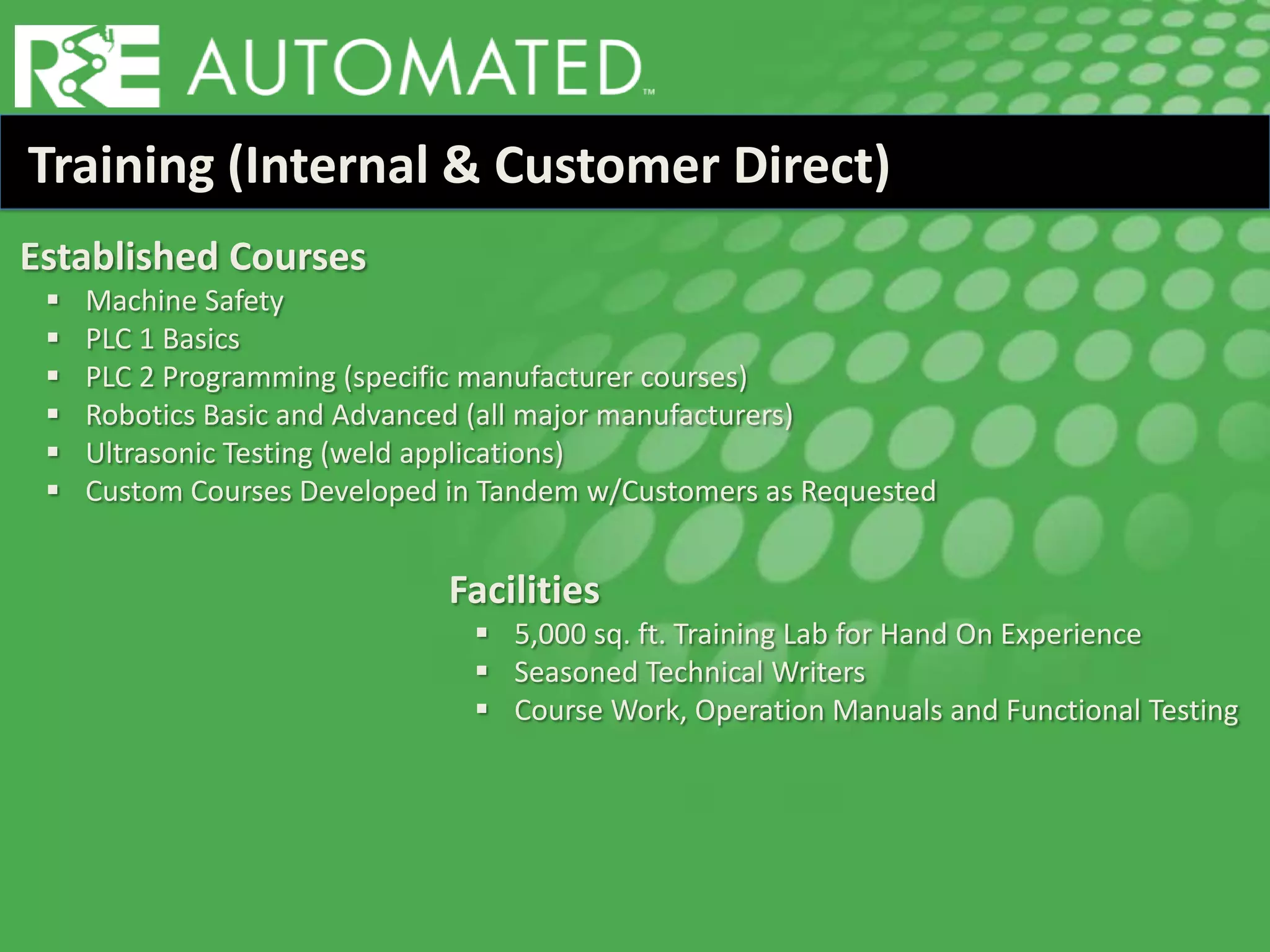

R&E Automated is a leader in providing automation engineering and consulting services with over 300 skilled employees. They are committed to technological advancement and customized solutions. R&E offers a wide range of services including robotic support, controls design, mechanical design, welding engineering, and training. Their mission is to remain at the forefront of automation solutions and provide efficient, cost-effective project management for clients.