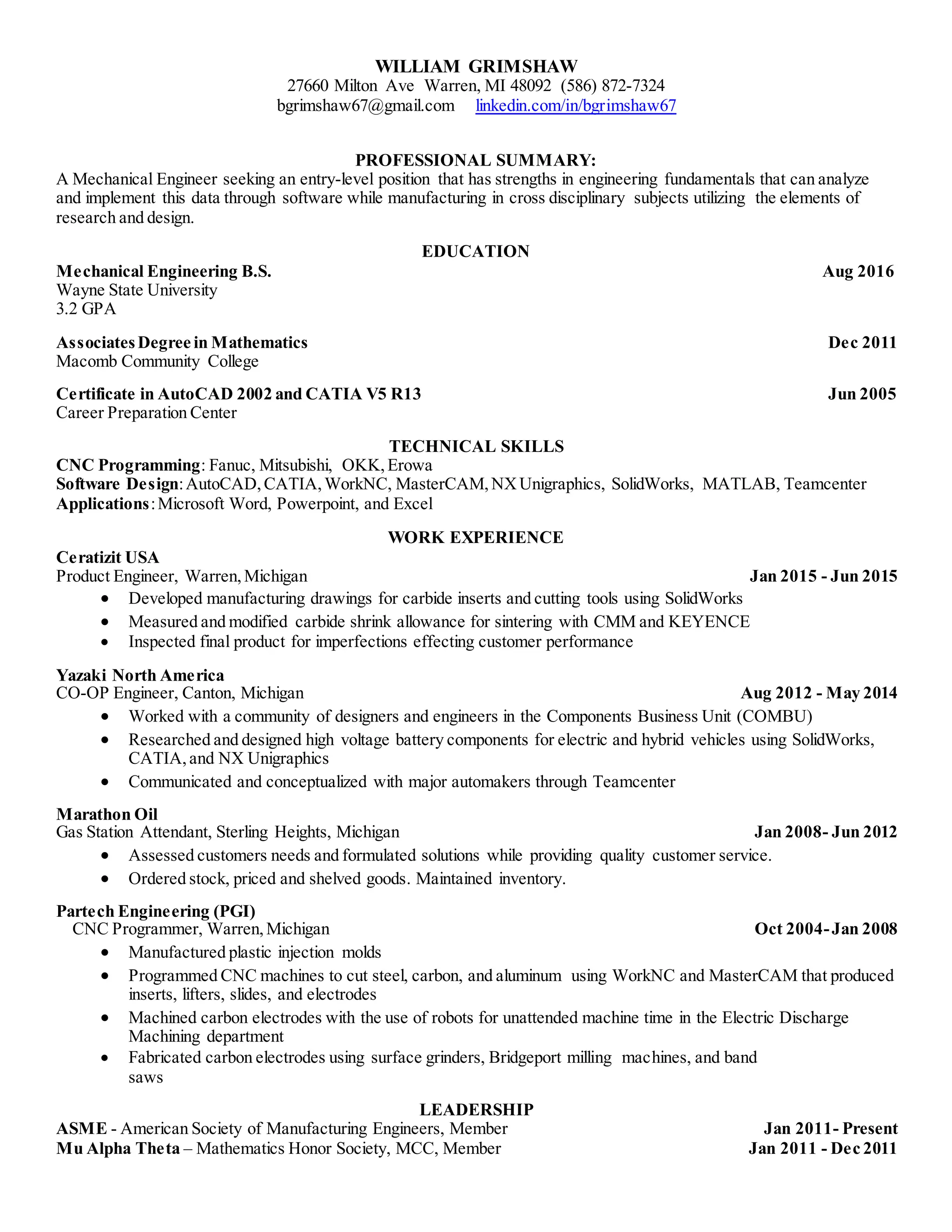

This document is a resume for William Grimshaw, a mechanical engineer seeking an entry-level position. He has a B.S. in Mechanical Engineering from Wayne State University and an Associate's Degree in Mathematics from Macomb Community College. His technical skills include CAD software like AutoCAD, CATIA, and SolidWorks as well as CNC programming. He has work experience as a Product Engineer developing manufacturing drawings and inspecting products, a CO-OP Engineer researching and designing automotive components, and a CNC Programmer manufacturing molds and machining parts.