This document provides an introduction to robotics, including:

- A definition of a robot as a programmable machine that can carry out complex actions with speed and precision without human intervention.

- Examples of what robots need to work including actuators for movement, sensors for obtaining information, and end effectors for manipulation.

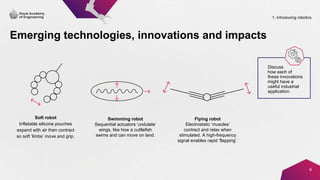

- Advantages and limitations of industrial robots are discussed, along with emerging technologies like soft robots, swimming robots, and flying robots that could help address limitations.

- Careers in robotics design, software, electromechanics, sales, and automation engineering are briefly outlined.

- The document encourages imagining future robot designs that could overcome current limitations.