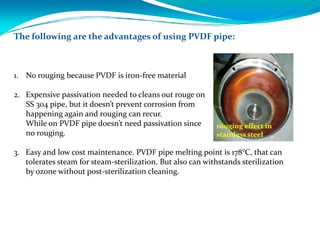

PVDF piping has several advantages over stainless steel piping for pharmaceutical and cosmetic industries. PVDF piping is iron-free and does not develop rouging particles like stainless steel piping, preventing contamination. Stainless steel piping requires expensive passivation cleaning to remove rouging which can still recur, while PVDF piping requires no passivation and is resistant to corrosion. PVDF piping also has better heat resistance, chemical resistance, and abrasion resistance than stainless steel piping, with lower maintenance costs and preventing production shutdowns from rouging contamination issues.