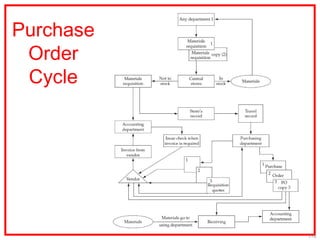

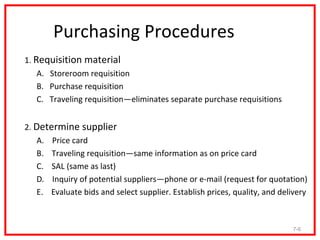

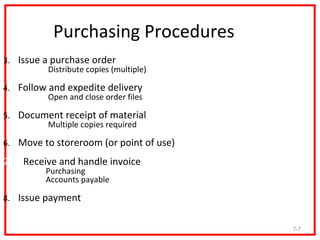

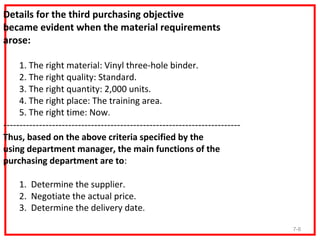

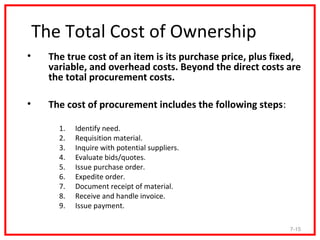

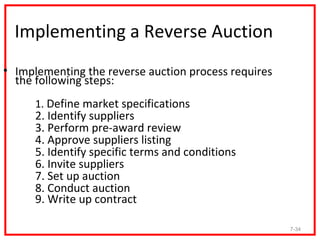

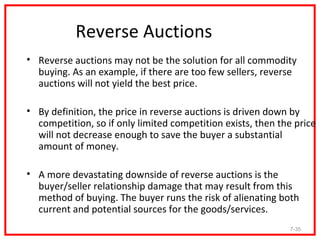

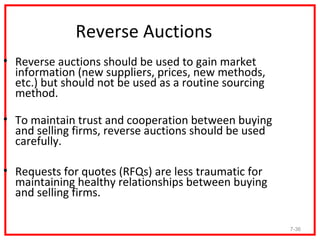

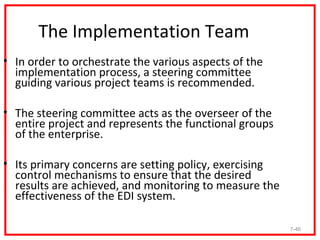

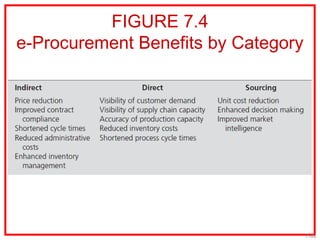

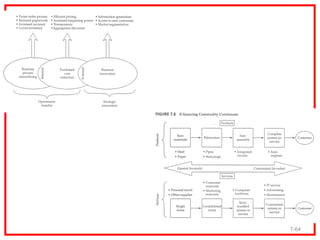

The chapter discusses purchasing procedures, e-purchasing, and systems contracting. It identifies the typical steps in the conventional purchasing cycle as requisitioning materials, determining suppliers, issuing purchase orders, expediting deliveries, receiving materials, and processing invoices. E-purchasing can reduce costs for indirect materials like office supplies through electronic ordering and reverse auctions. However, direct materials purchasing requires close supplier relationships not suited for e-procurement. Electronic data interchange (EDI) allows electronic transmission of orders and invoices but implementation requires overcoming resistance to change.