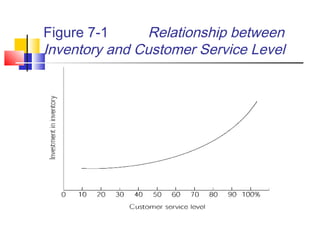

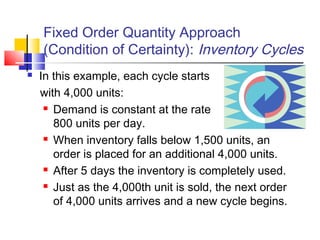

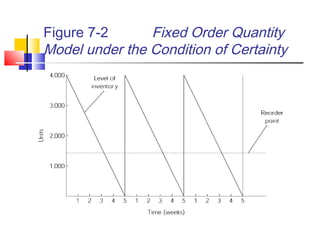

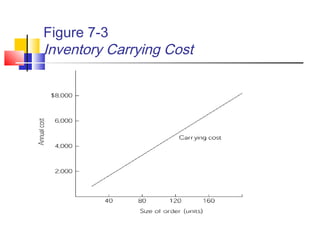

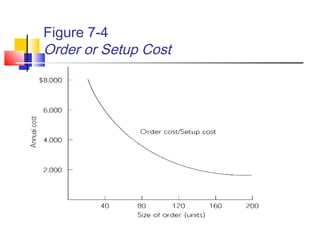

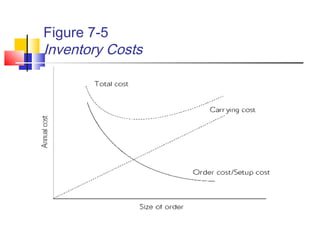

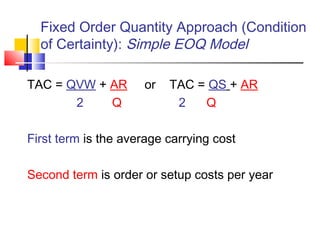

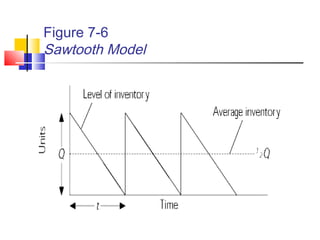

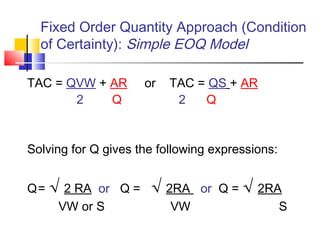

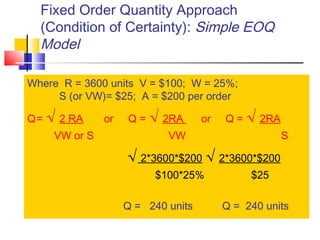

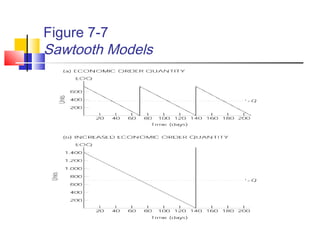

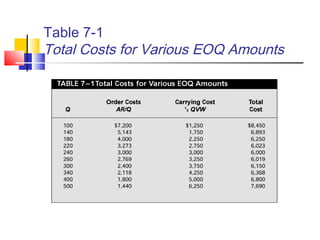

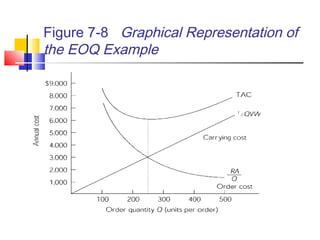

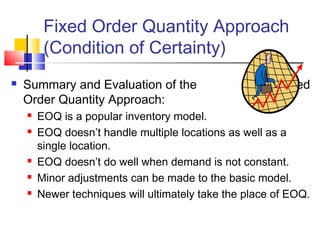

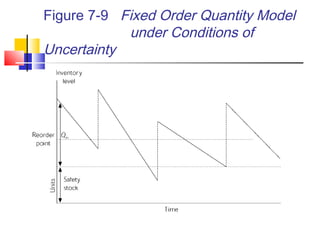

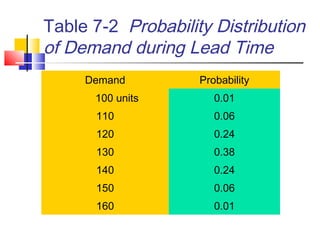

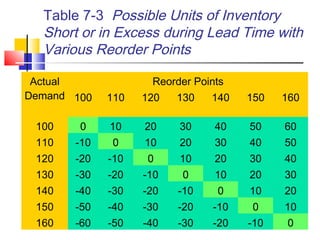

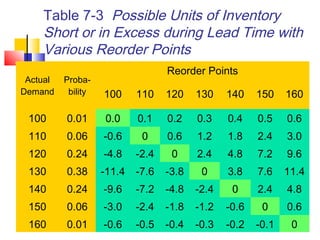

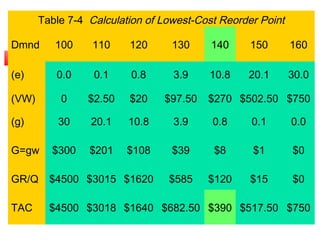

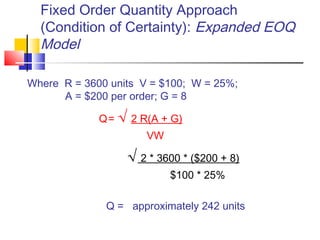

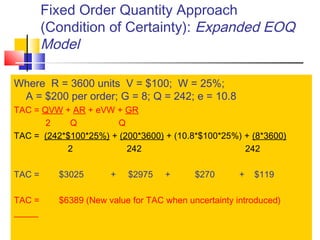

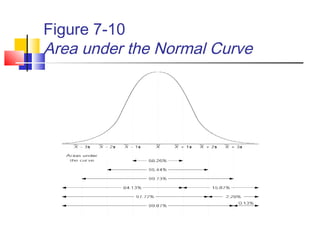

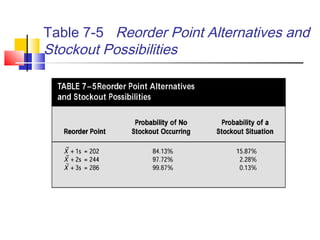

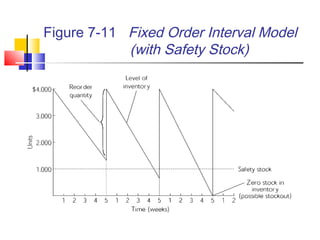

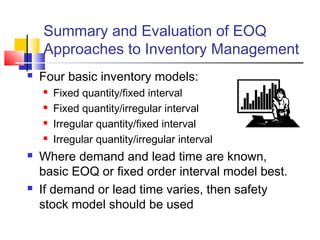

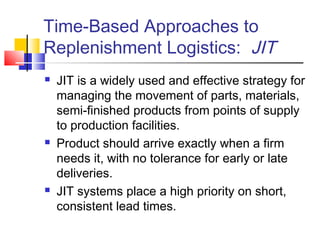

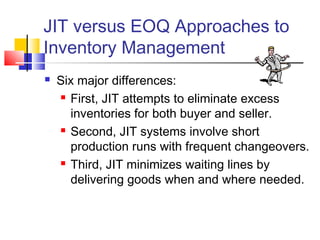

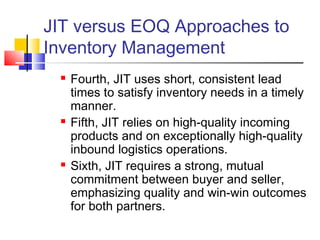

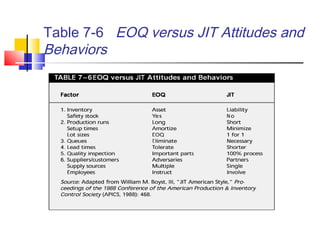

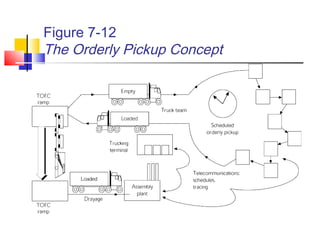

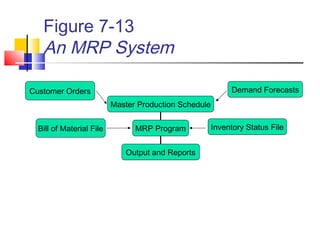

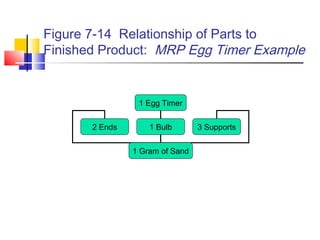

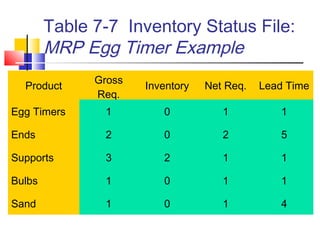

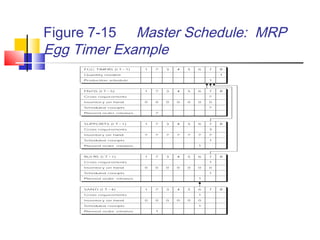

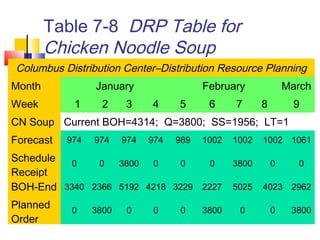

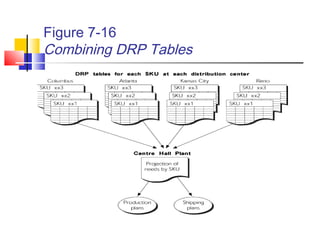

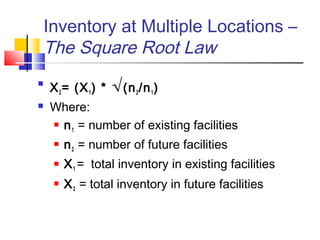

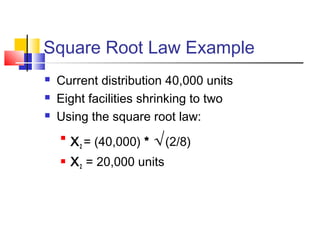

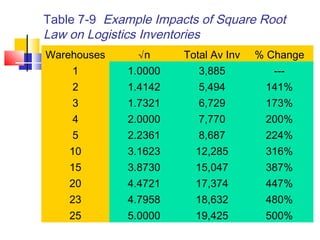

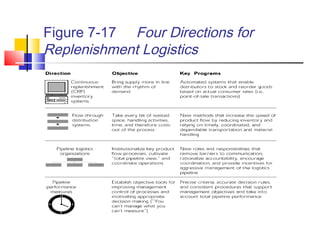

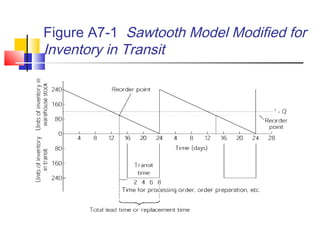

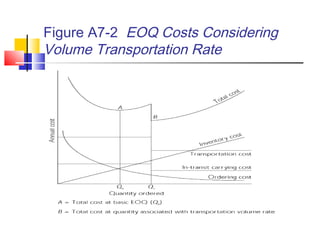

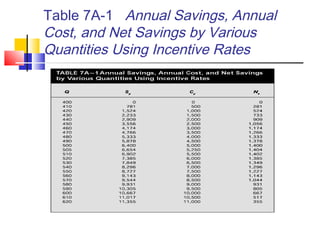

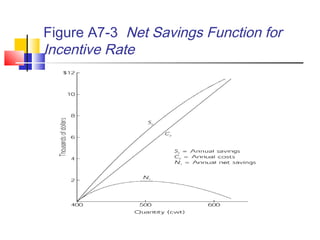

The document discusses various approaches to inventory decision making and management. It begins by outlining the key learning objectives which include understanding different inventory management approaches like EOQ, JIT, MRP, and DRP. It then explains the basic EOQ (Economic Order Quantity) model and how it can be applied under conditions of certainty and uncertainty. The document also discusses fixed order interval approaches and compares EOQ to other approaches like JIT. It provides examples and diagrams to illustrate inventory management concepts.