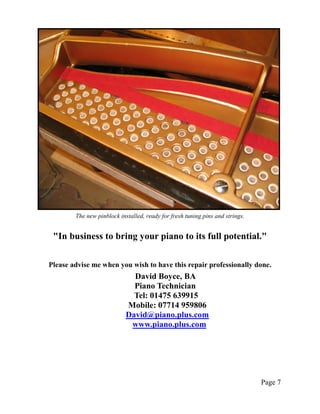

The document discusses replacing a grand piano's pinblock. It explains that a pinblock must grip tuning pins tightly to maintain tuning, and deteriorated pinblocks can cause tuning instability. Replacing a pinblock is often best when laminations have separated, pins are loose, or the pinblock is mushy. The process requires removing the plate and precisely cutting, fitting, and drilling a new pinblock to the plate to ensure tuning stability. The level of precision makes replacing the pinblock best done by a technician rather than at home.