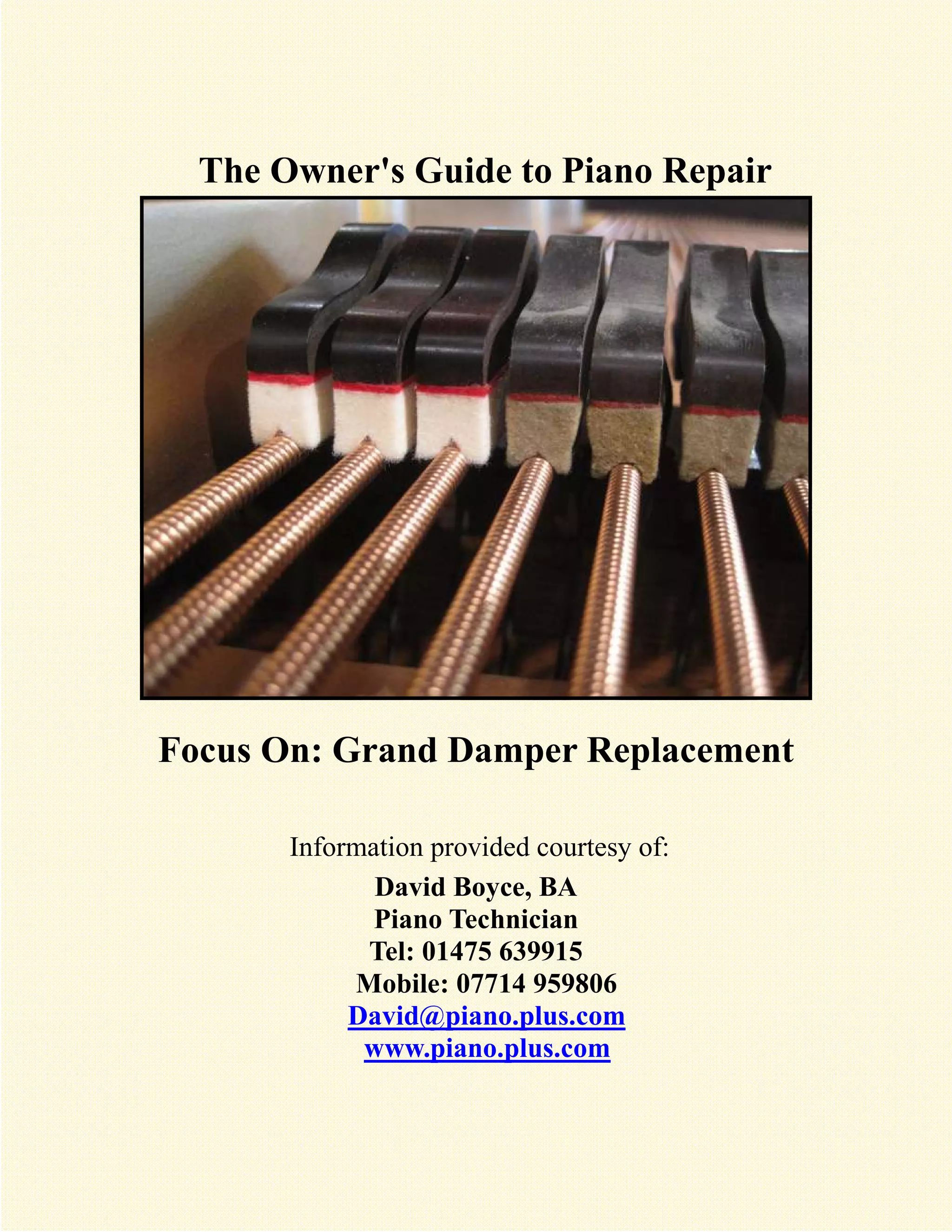

This owner's guide provides detailed information on replacing worn dampers in grand pianos, which are crucial for controlling sound cessation. It outlines symptoms of ineffective dampers, the physical workings of dampers, and the repair process, including necessary adjustments after installation. The guide emphasizes the importance of high-quality materials and precision for optimal piano performance.