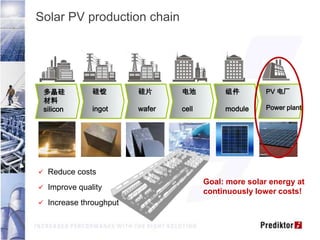

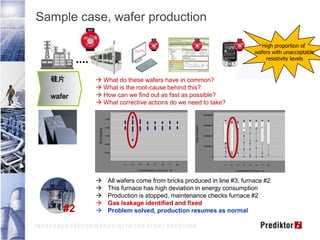

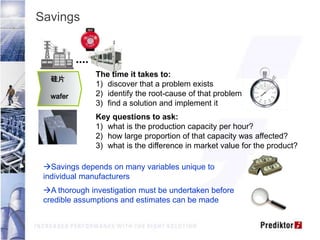

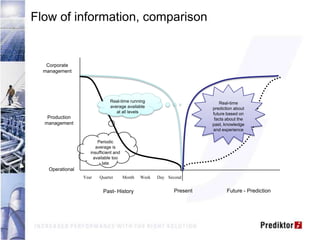

This document discusses process visibility and optimization in the solar PV value chain. It introduces Prediktor, a company that provides consulting services and industrial IT solutions to optimize manufacturing processes. Prediktor helps solar PV manufacturers reduce costs, improve quality, and increase throughput by integrating machine data, providing analytical tools, and consulting on process optimization. The document outlines challenges manufacturers face without effective data collection and analysis systems, and how Prediktor's solutions can help provide real-time visibility into production data to identify and address issues.