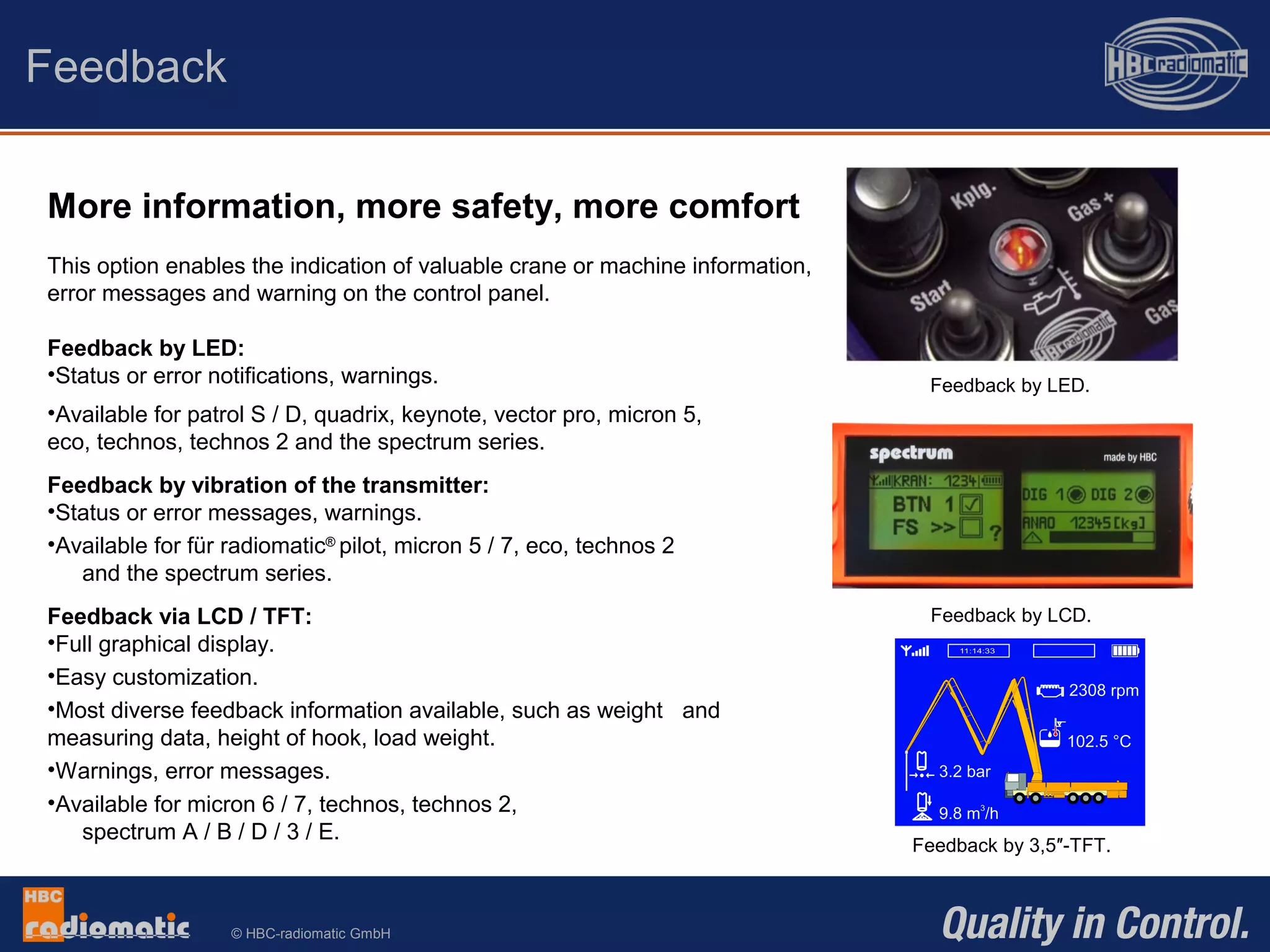

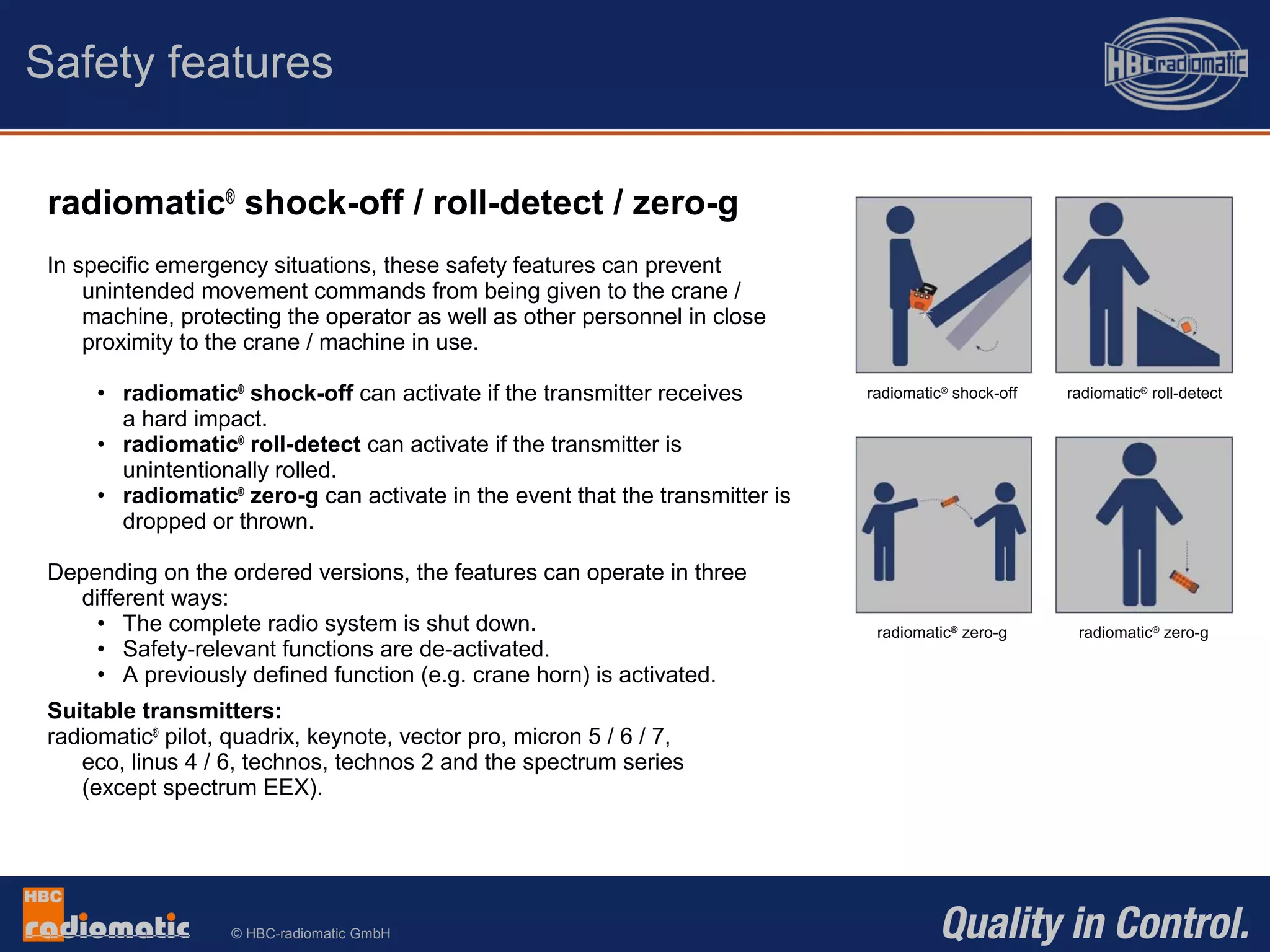

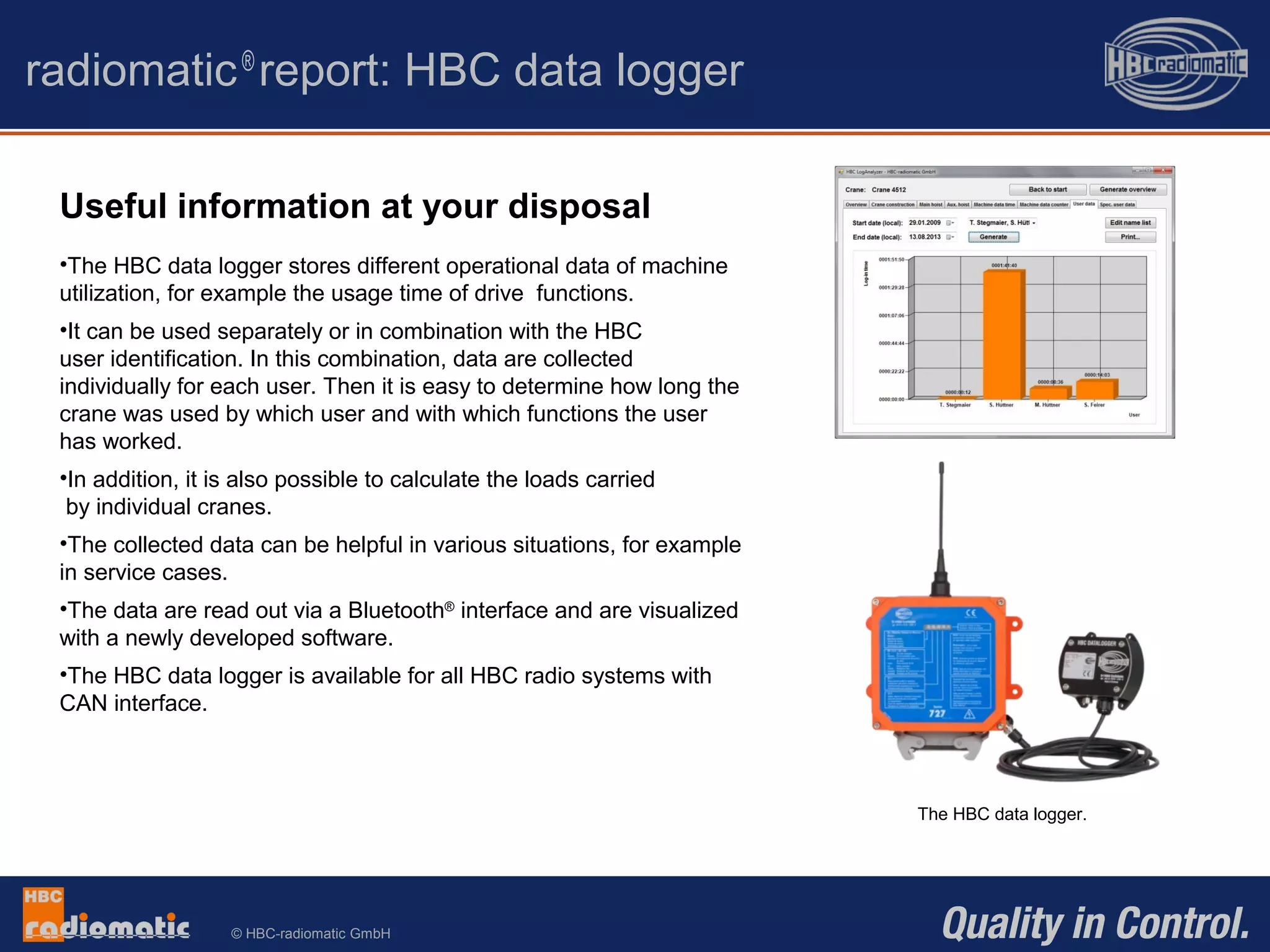

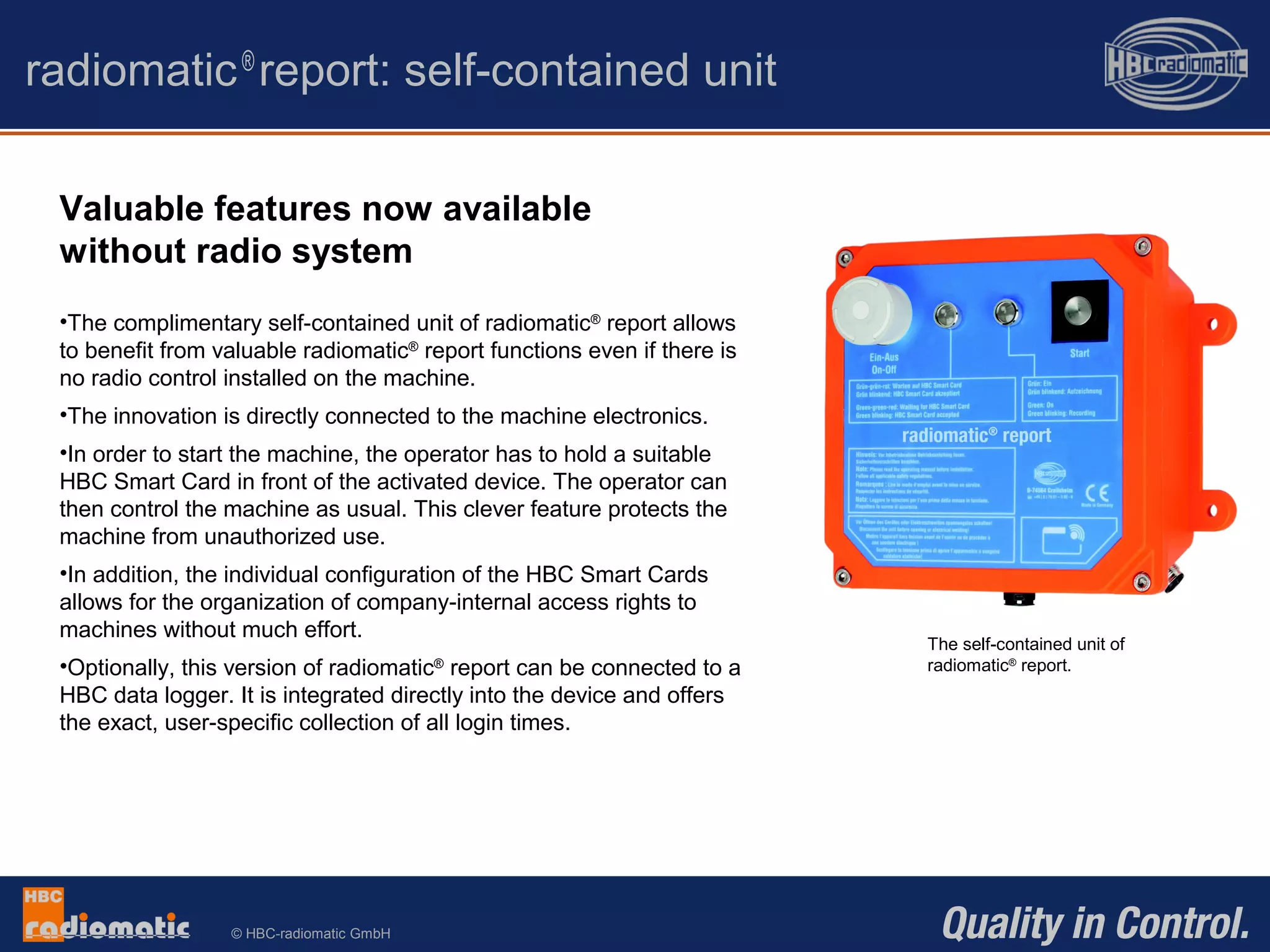

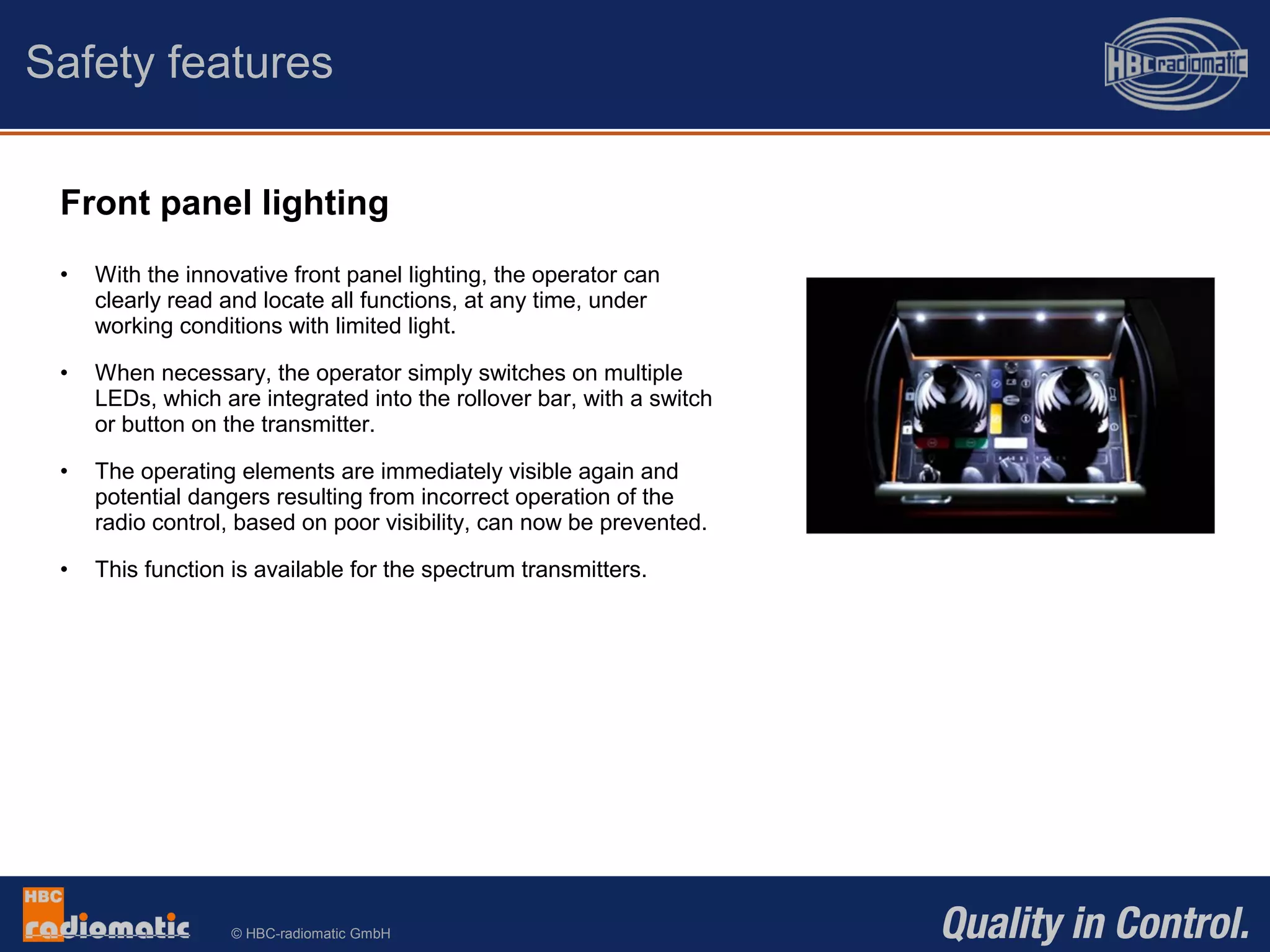

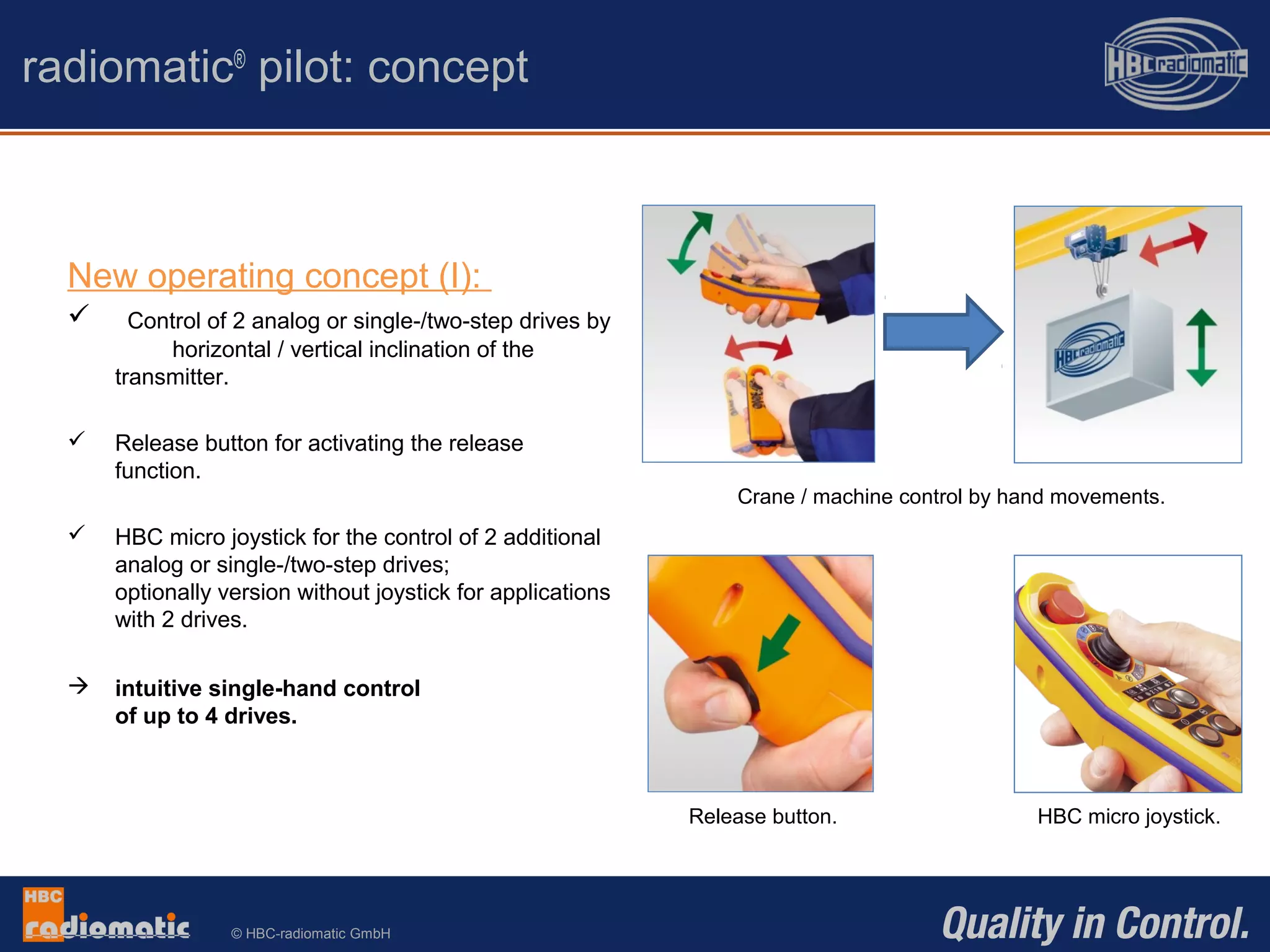

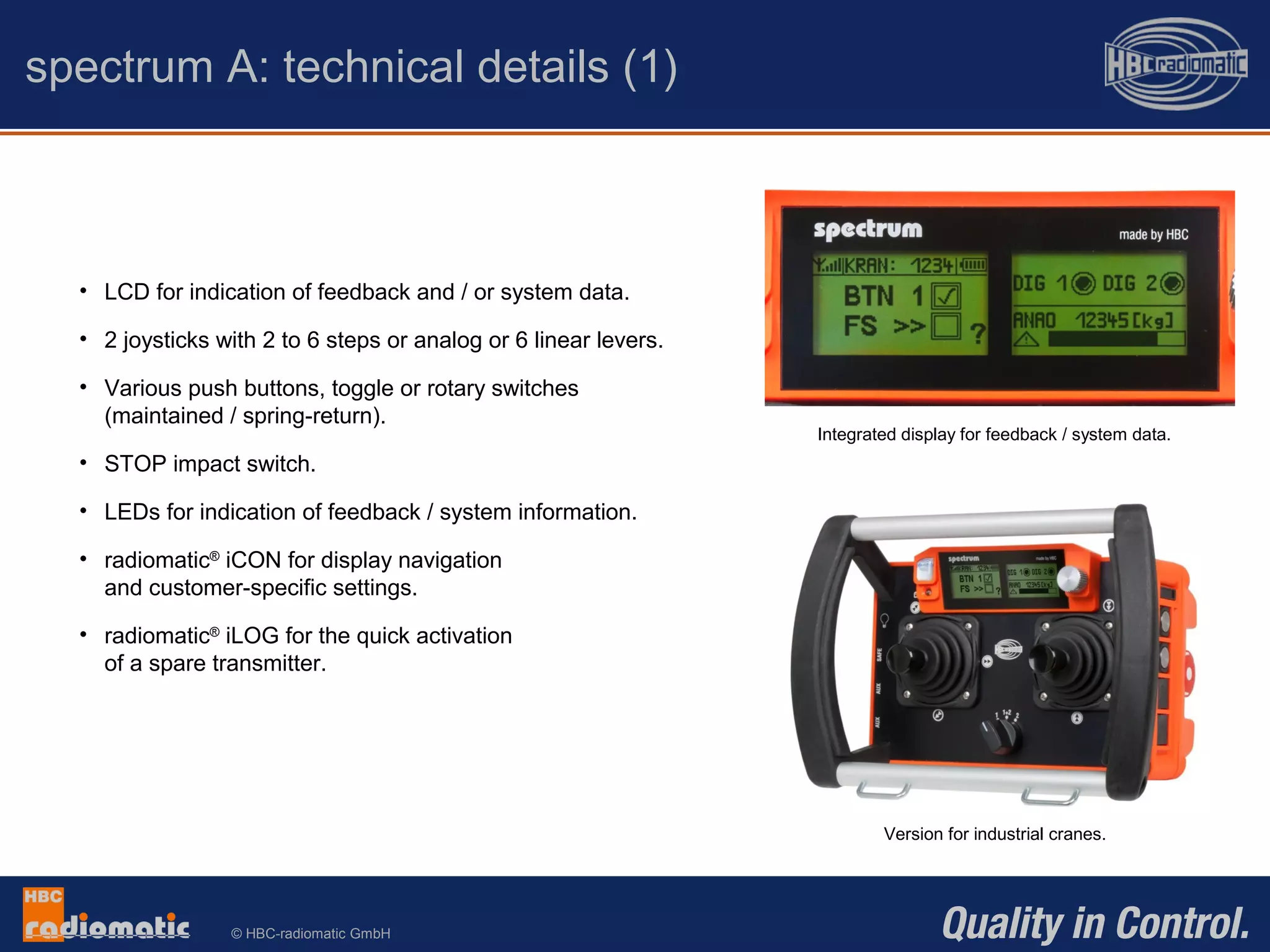

This document provides information on HBC-radiomatic GmbH, a company that produces radio control systems for industrial use. It describes their transmitter families and various features including feedback options, safety features, user identification and access management, data logging capabilities, and customizable spectrum transmitter models. The document highlights HBC-radiomatic's ability to provide tailored radio technology solutions for industrial cranes and other machinery applications.