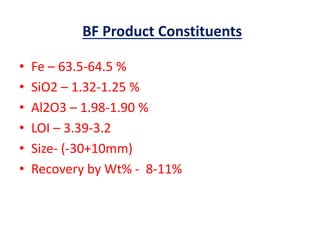

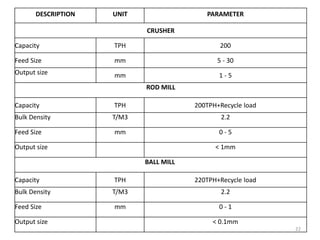

The document describes the process flow of a beneficiation plant. It involves various steps like scrubbing, comminution using crushers and mills, gravity separation using jigs, magnetic separation using WHIMS, classification using hydrocyclones and dewatering using thickeners and filters. Modifications to the plant included adding more WHIMS to reduce iron in tailings and increase recovery. Charts show monthly quality reports and mass balance of the plant. Equipment details like capacities and specifications of crushers, mills, separators are also provided.