Embed presentation

Download as PDF, PPTX

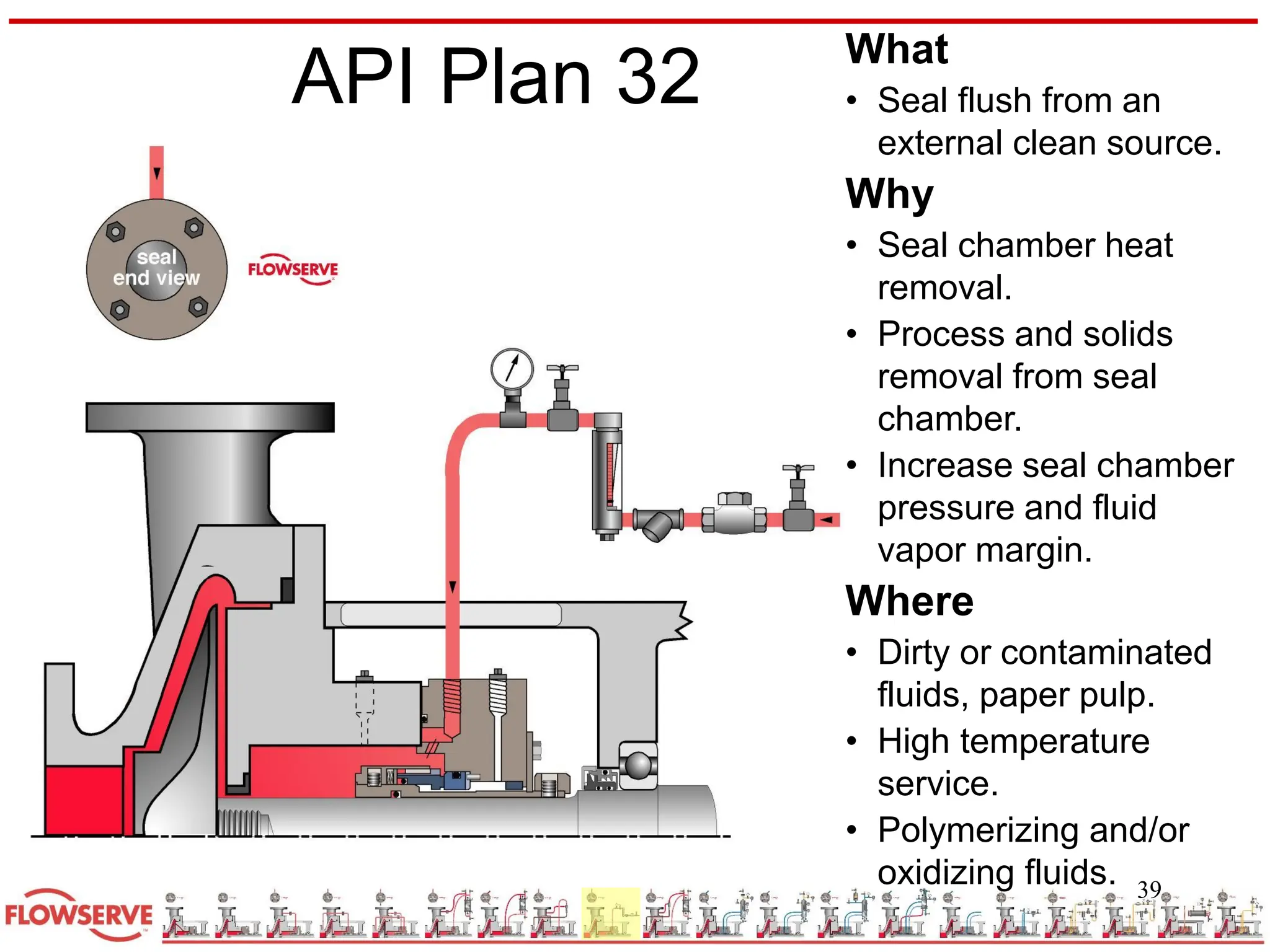

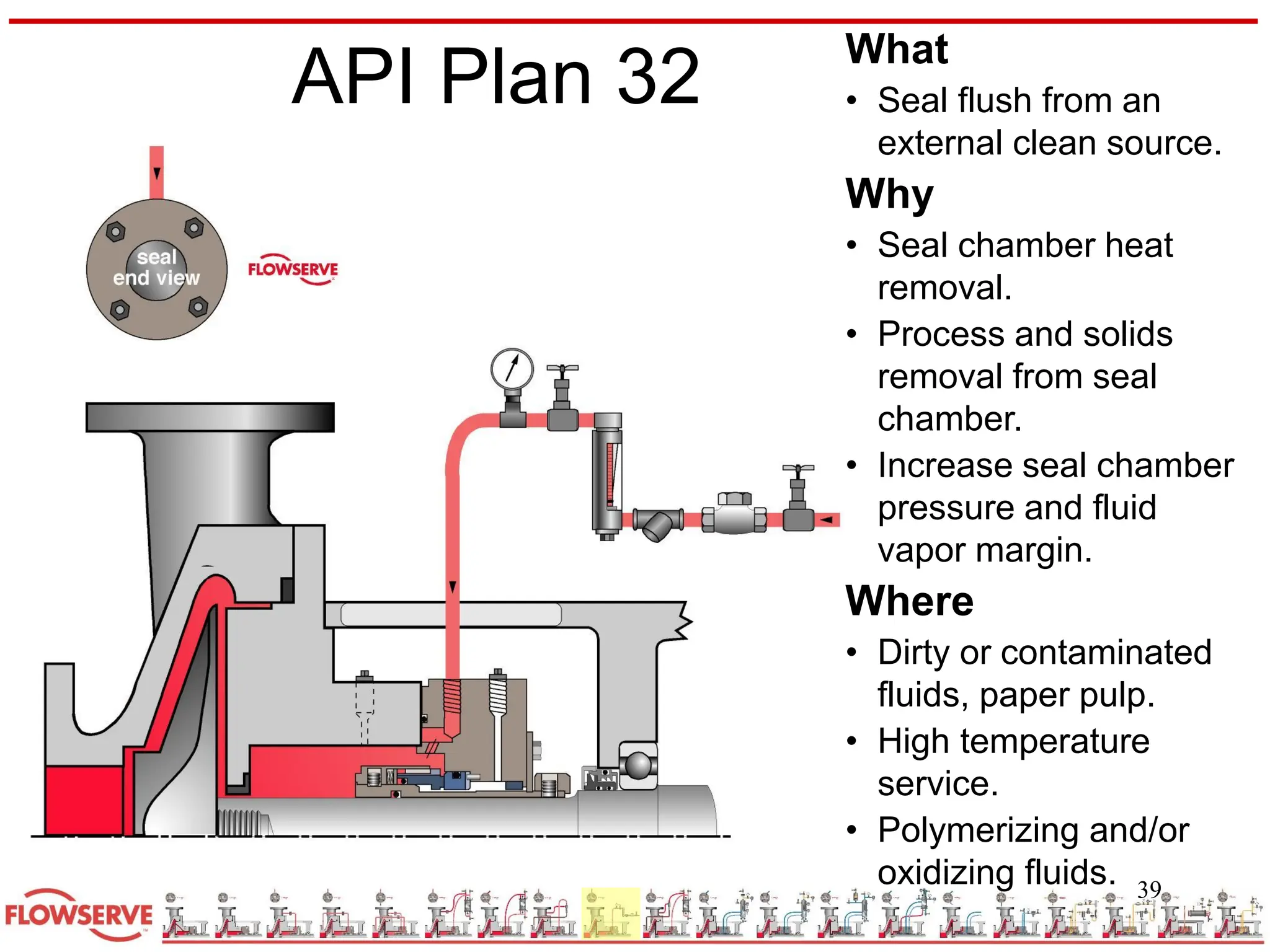

This document discusses API seal flush plans for pumps. Plan 32 uses an external clean fluid source to flush the seal chamber for heat removal, solids removal, and increasing seal chamber pressure. Plan 32 is used for dirty or contaminated fluids, high temperature service, or polymerizing/oxidizing fluids. Preventative maintenance includes using a throat bushing, regulating injection flow and pressure, and ensuring compatibility. Plan 41 flushes the seal from the pump discharge through a cyclone separator and cooler, combining aspects of Plans 21 and 31. Plan 41 is used for high temperature service under 350°F and dirty or contaminated non-polymerizing fluids.