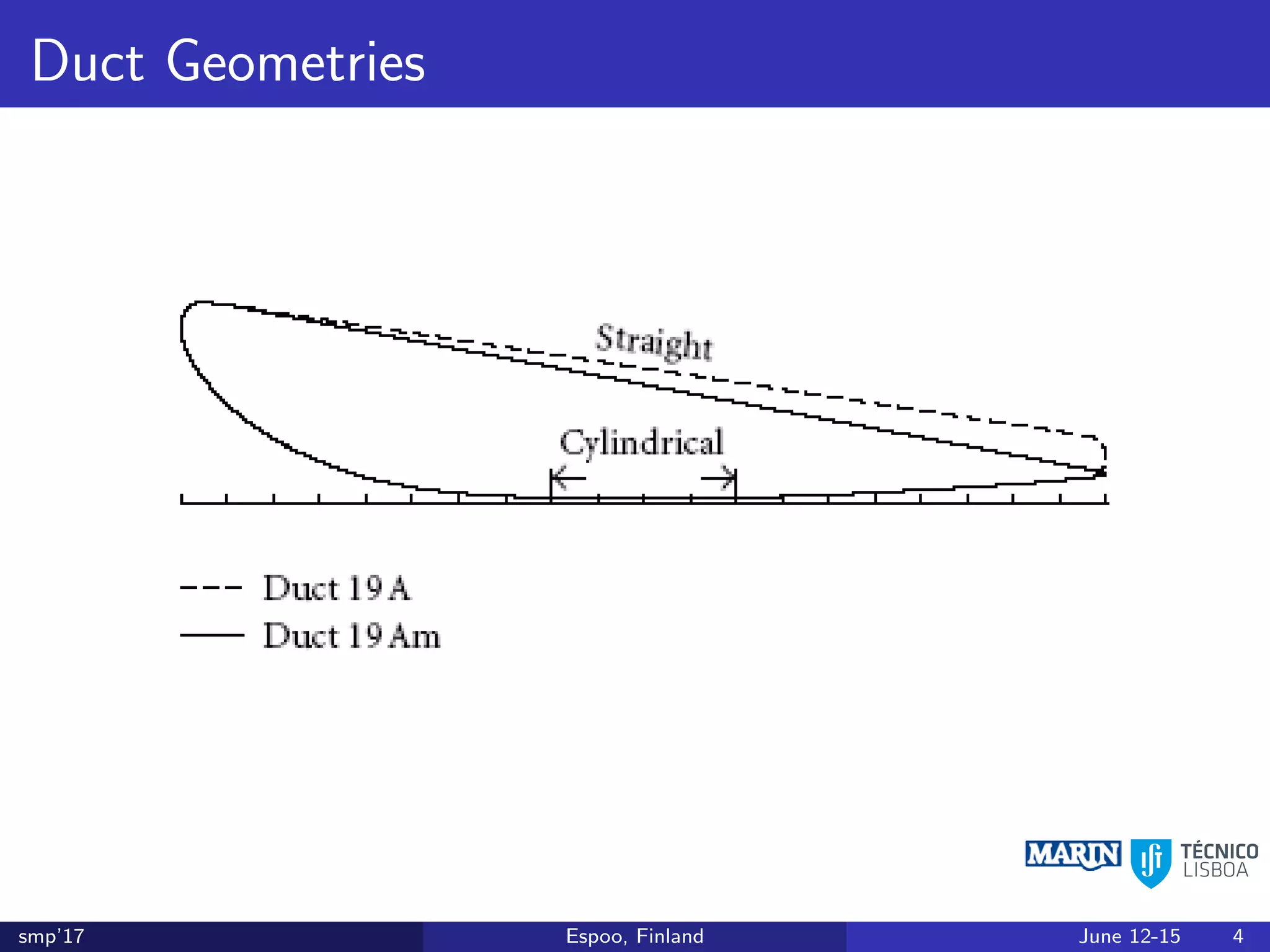

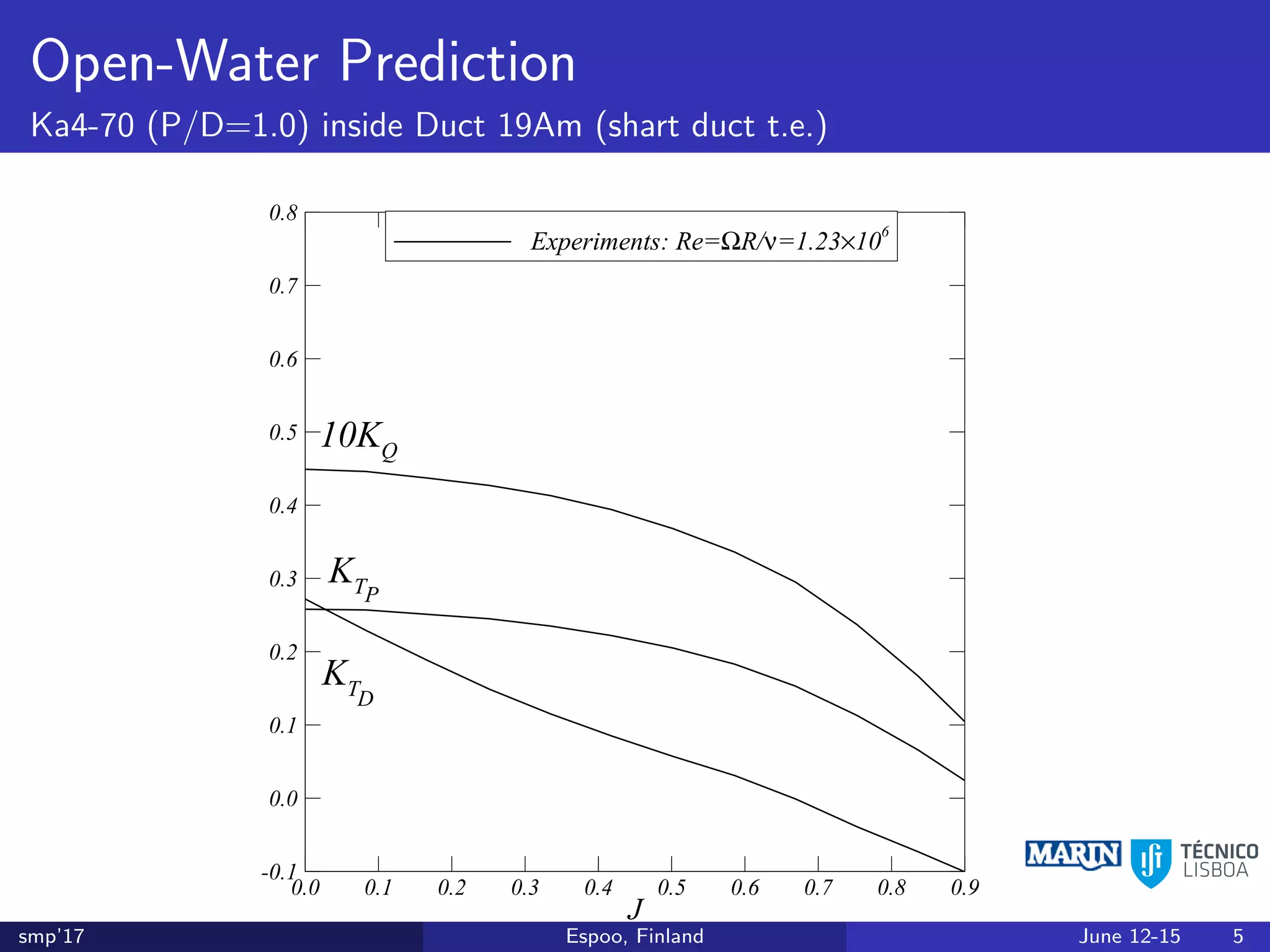

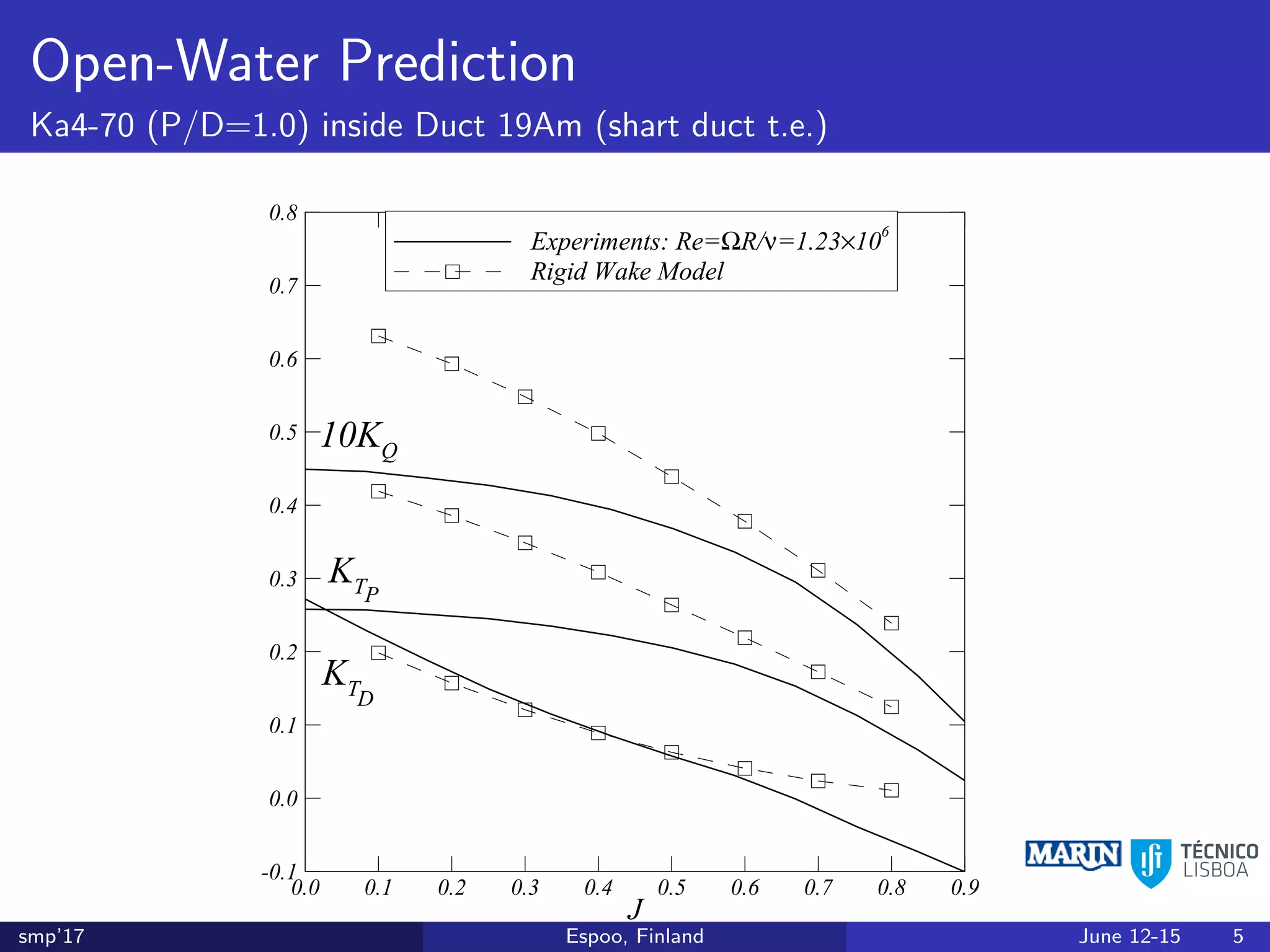

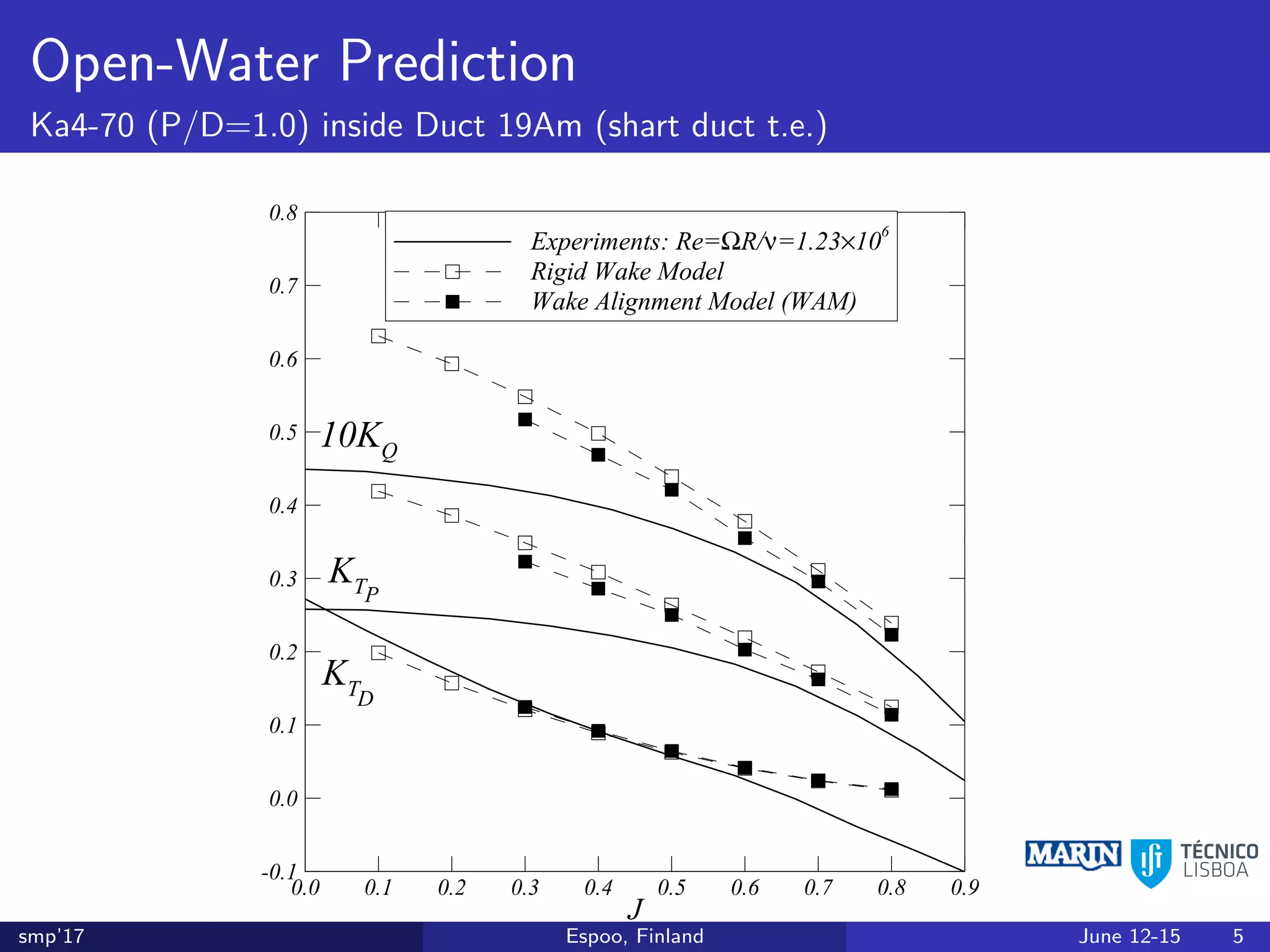

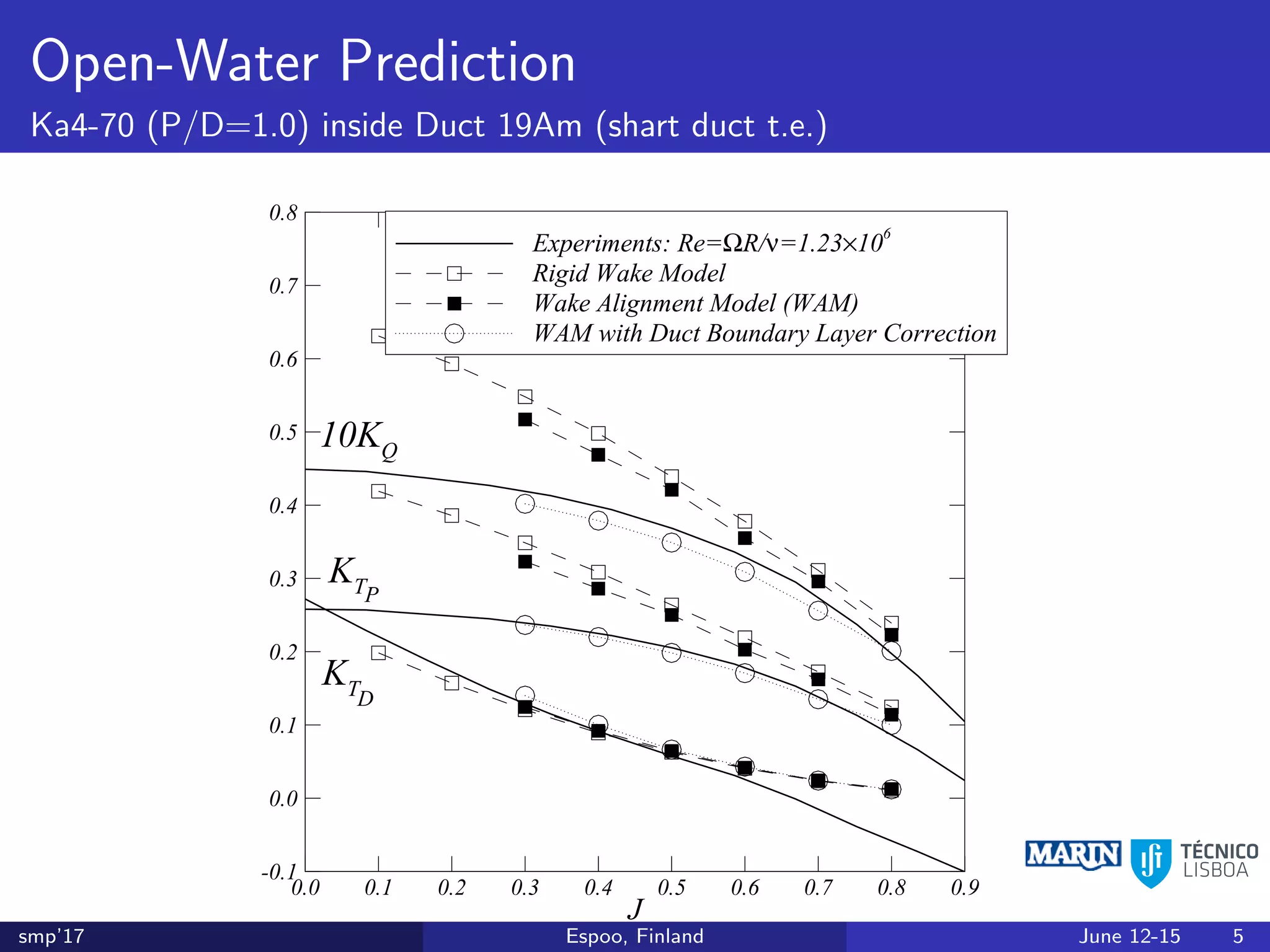

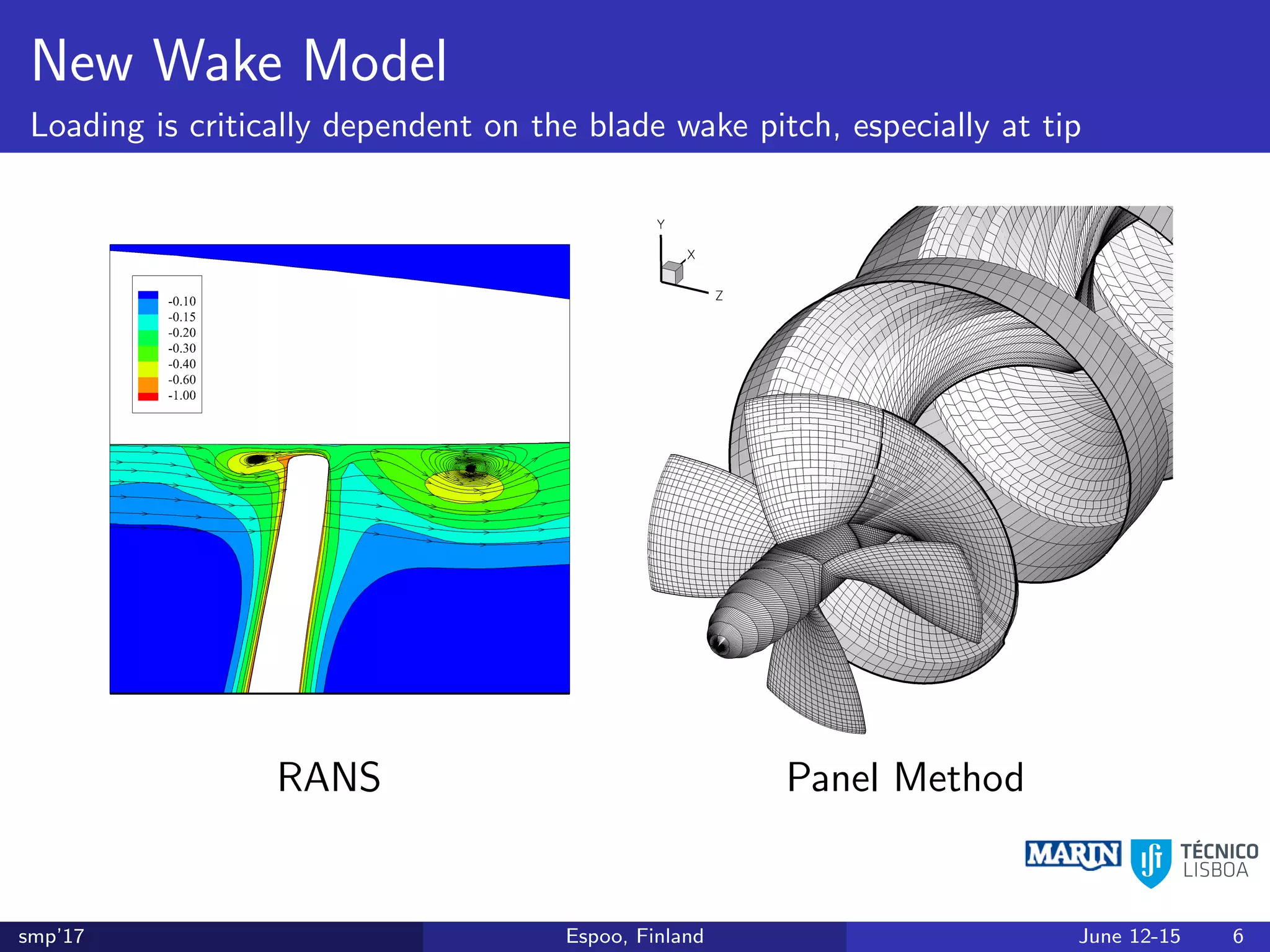

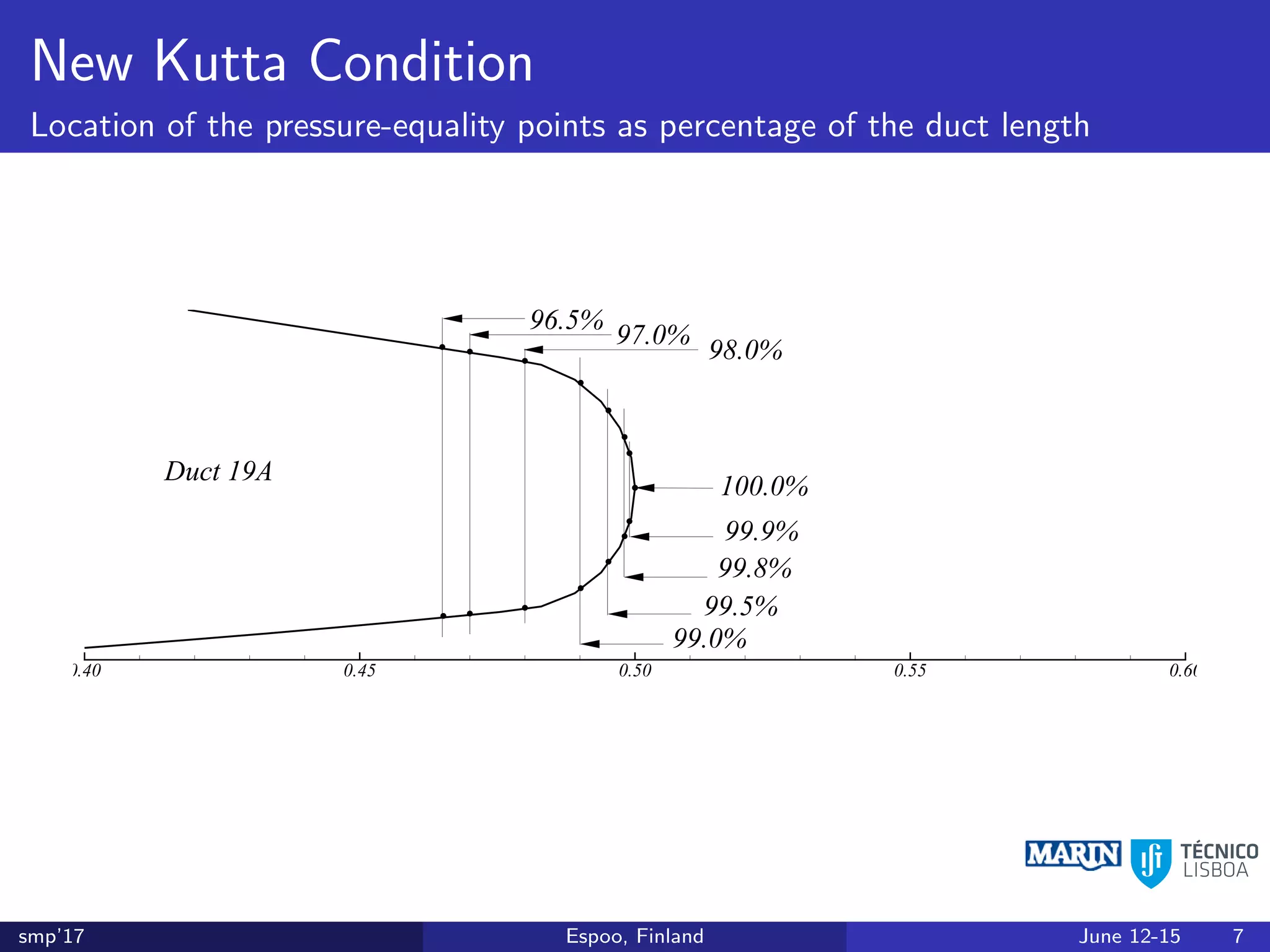

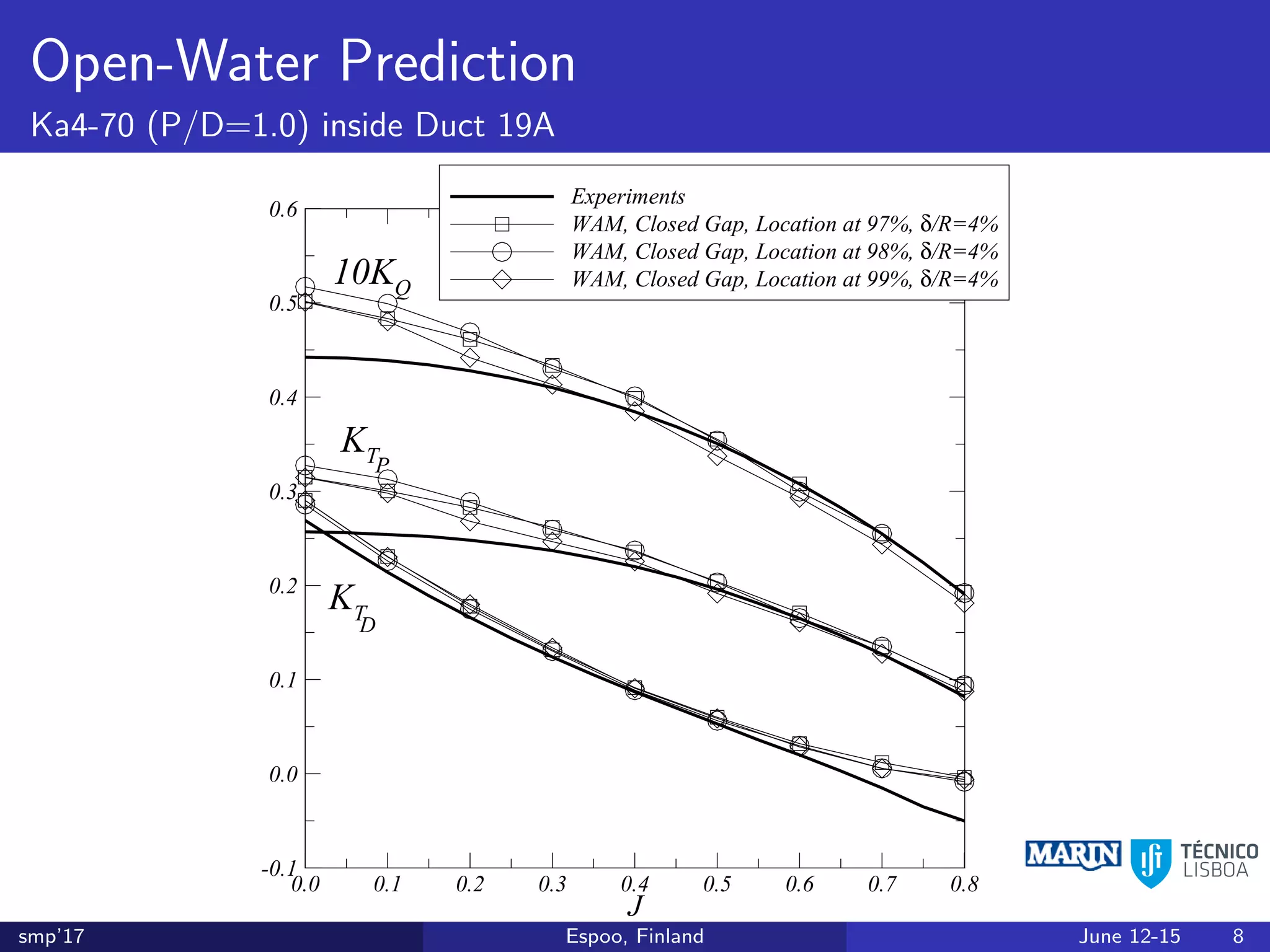

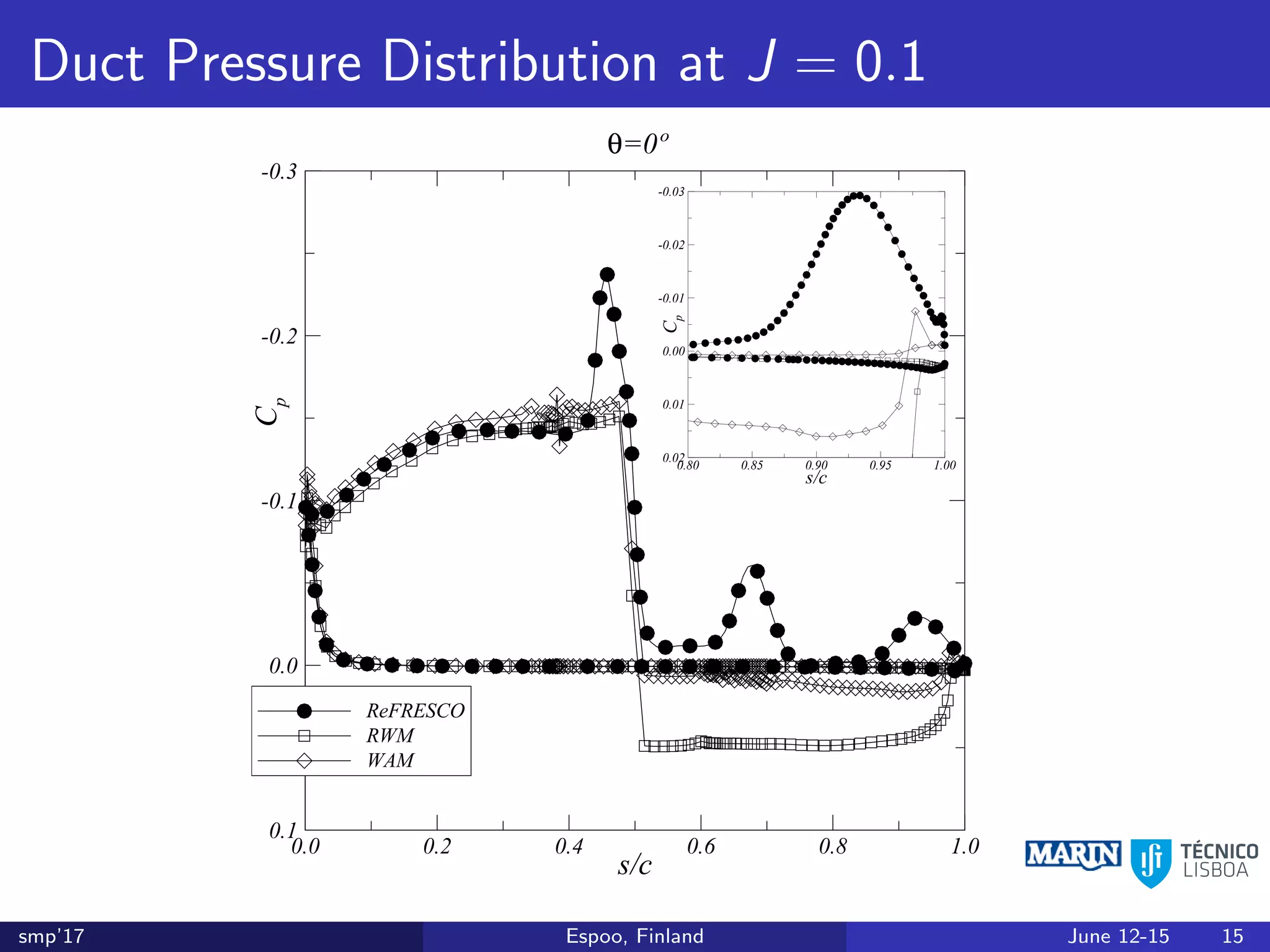

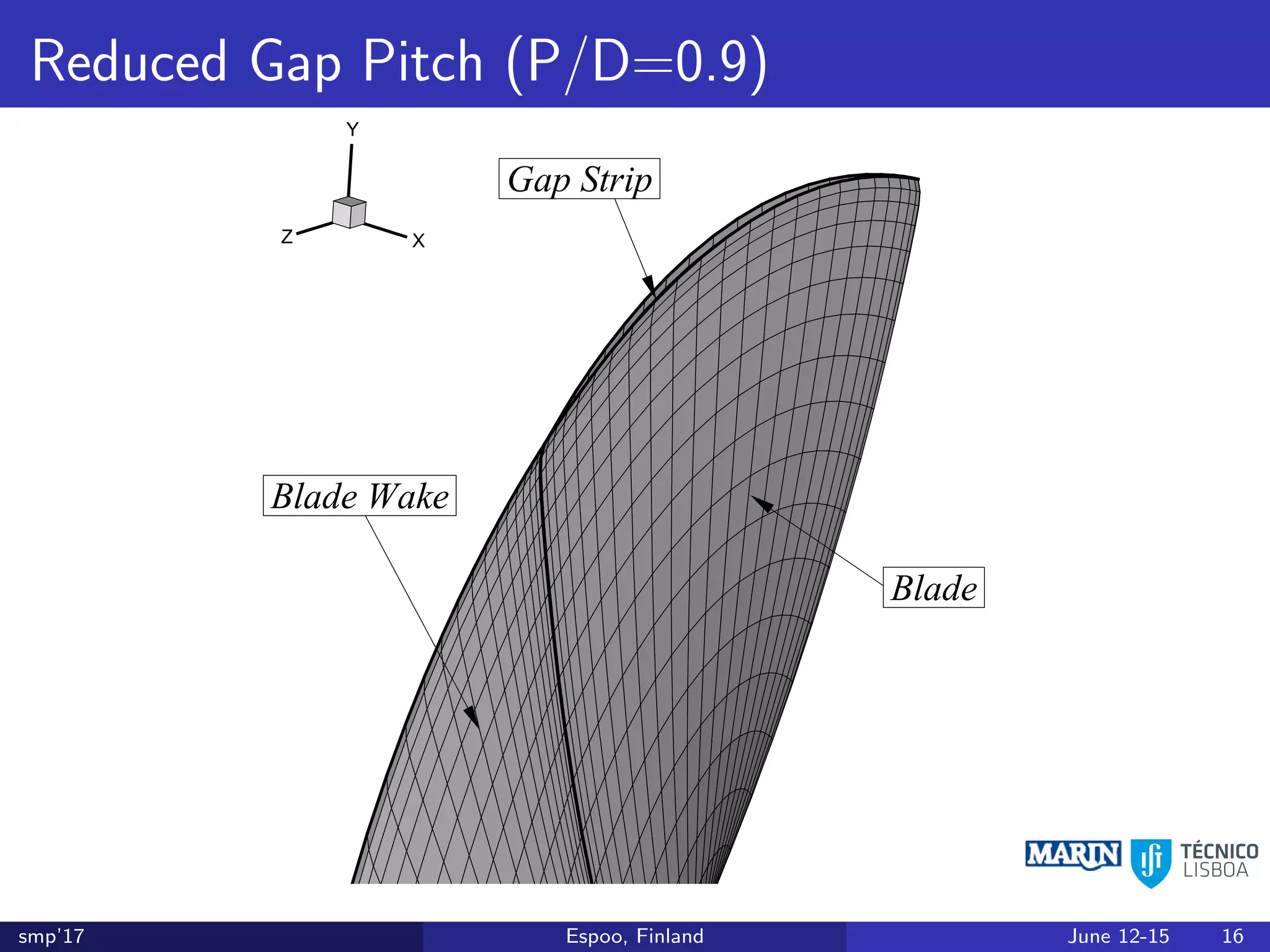

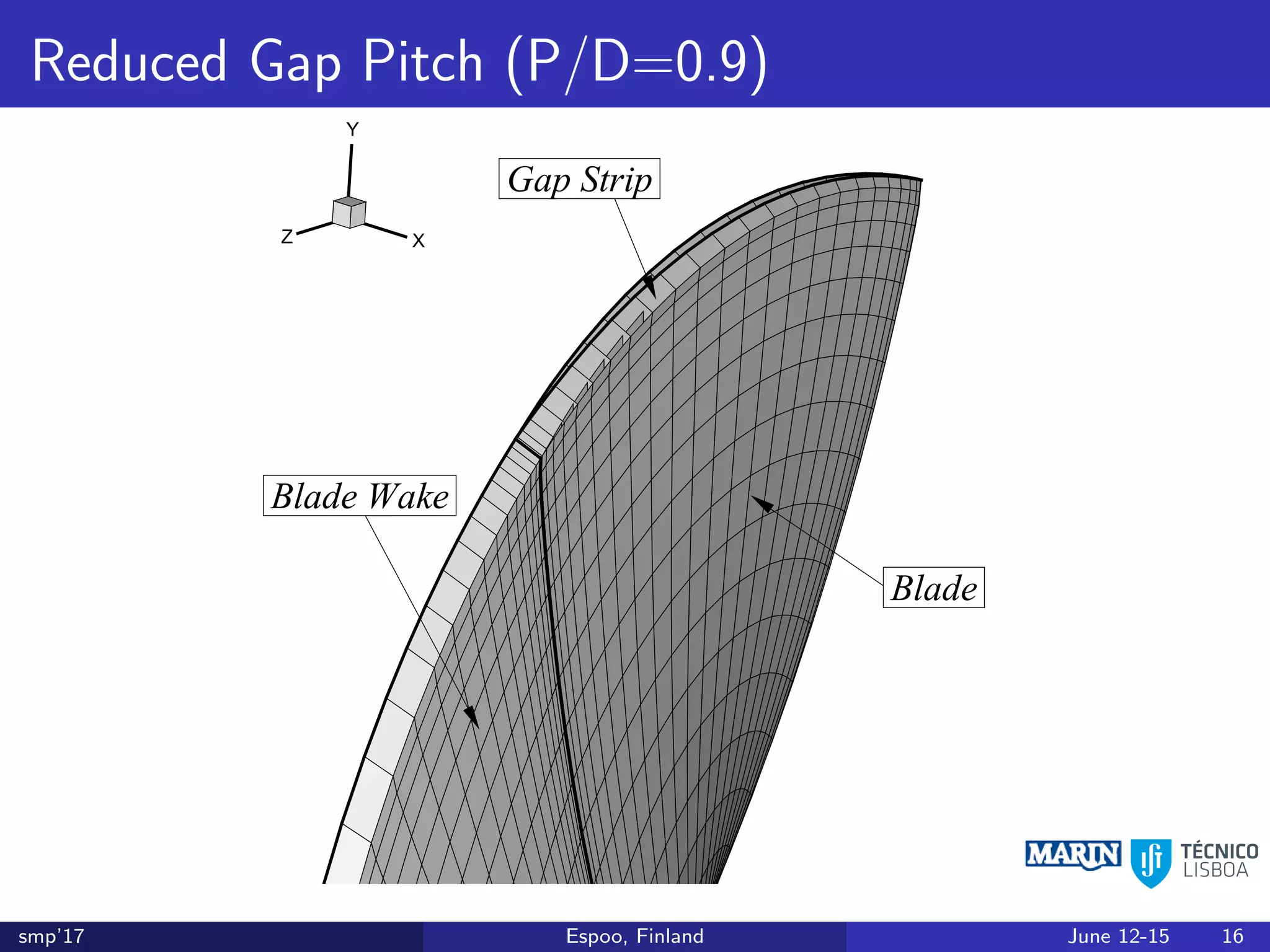

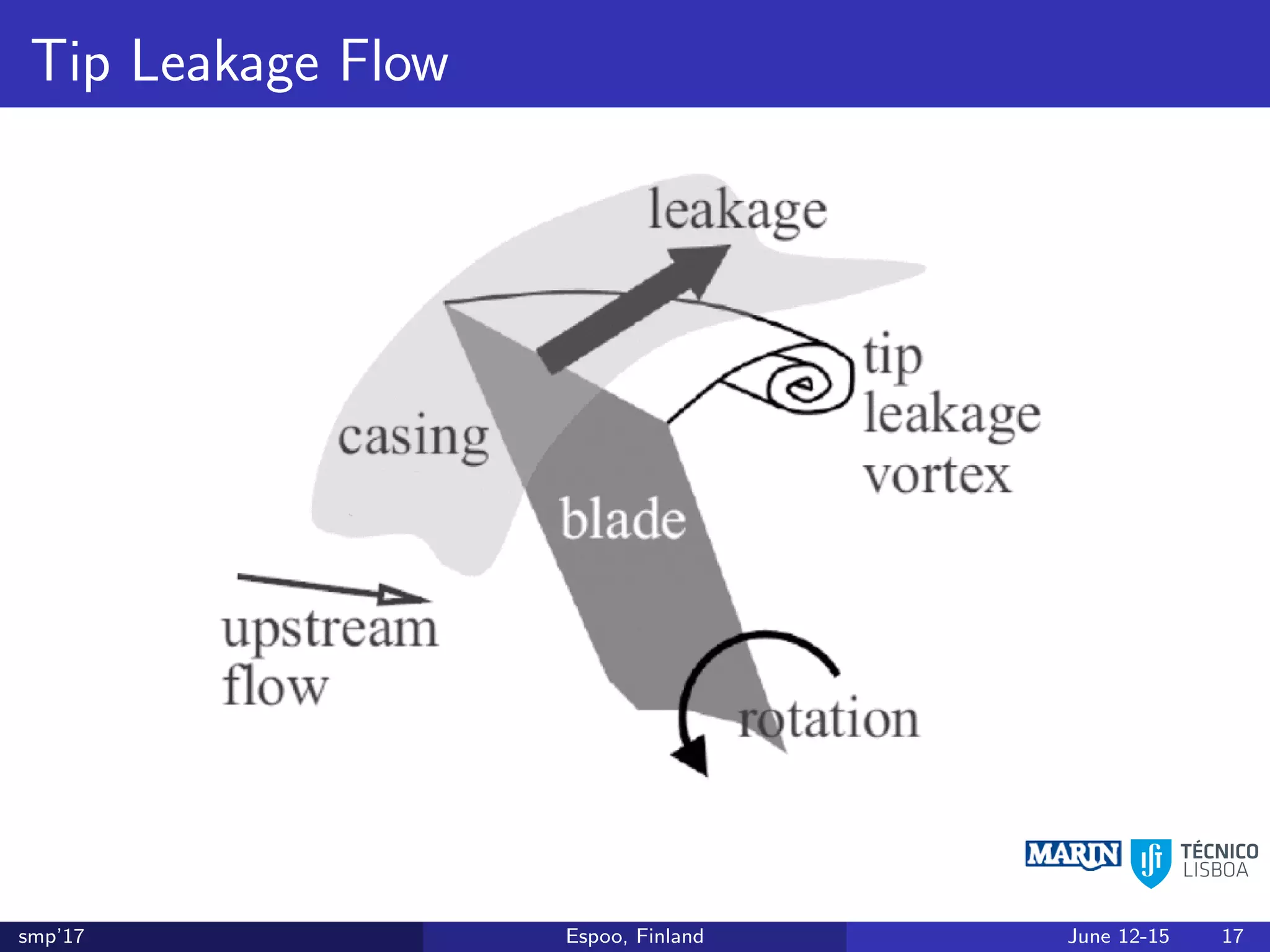

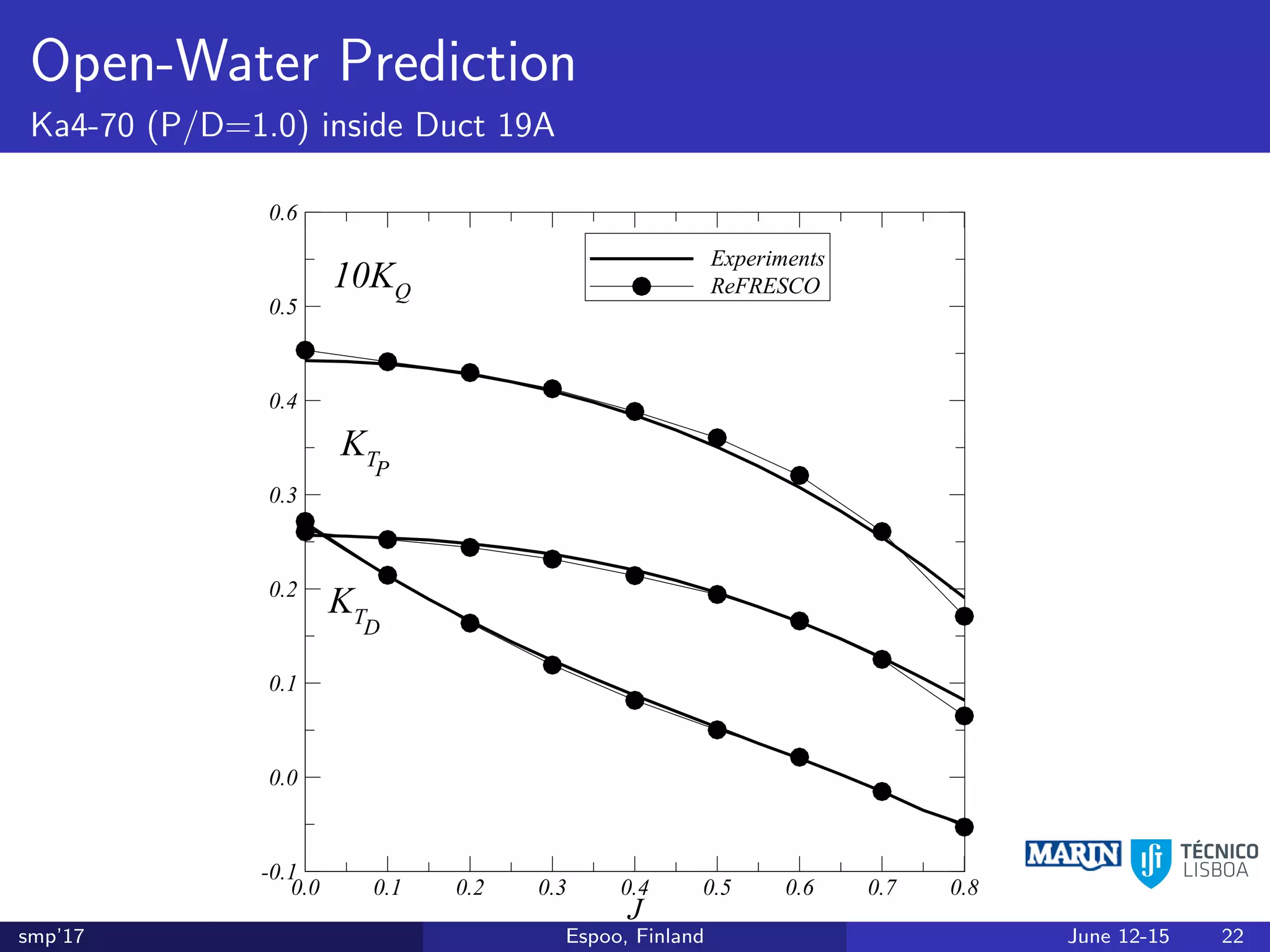

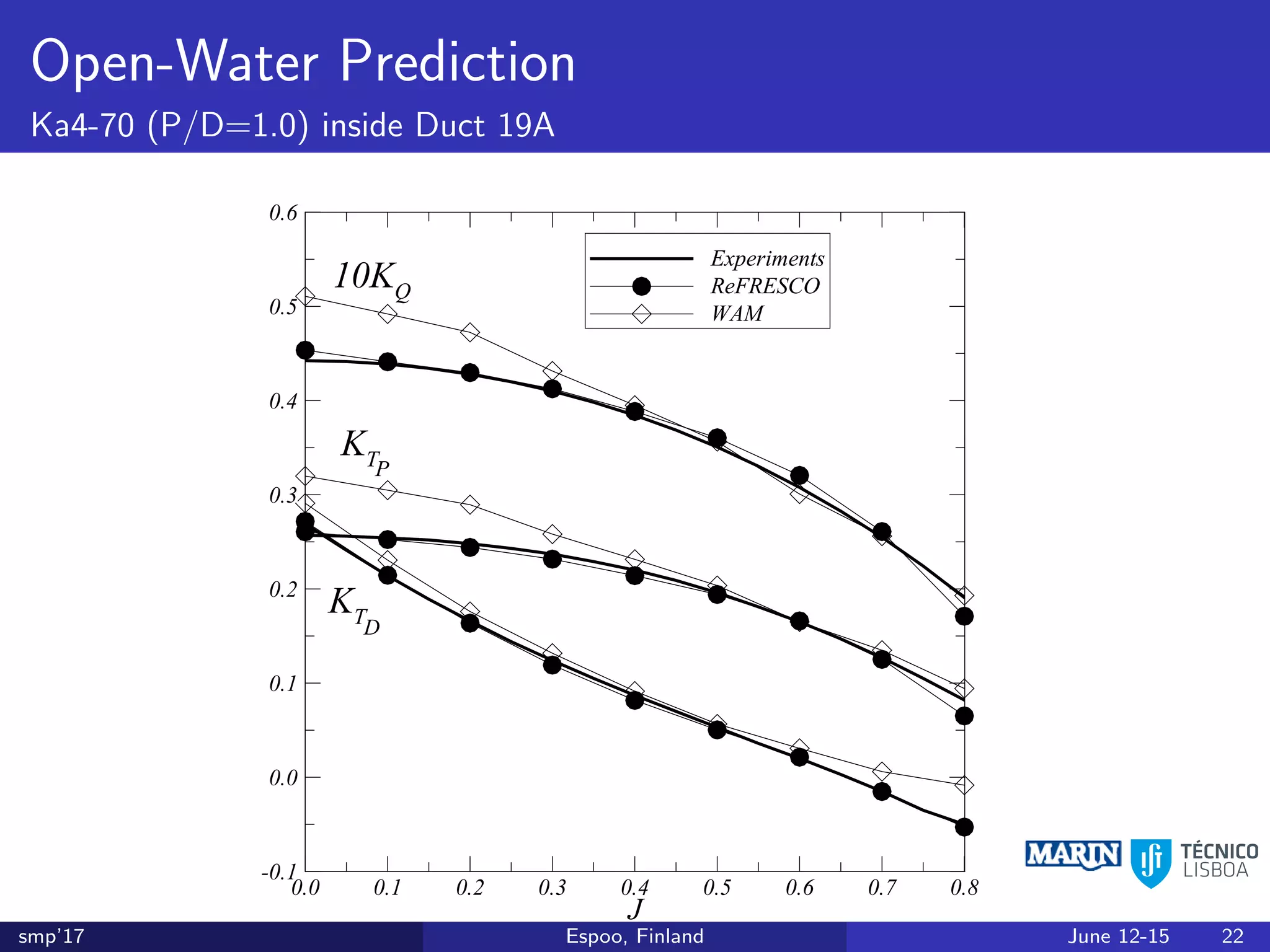

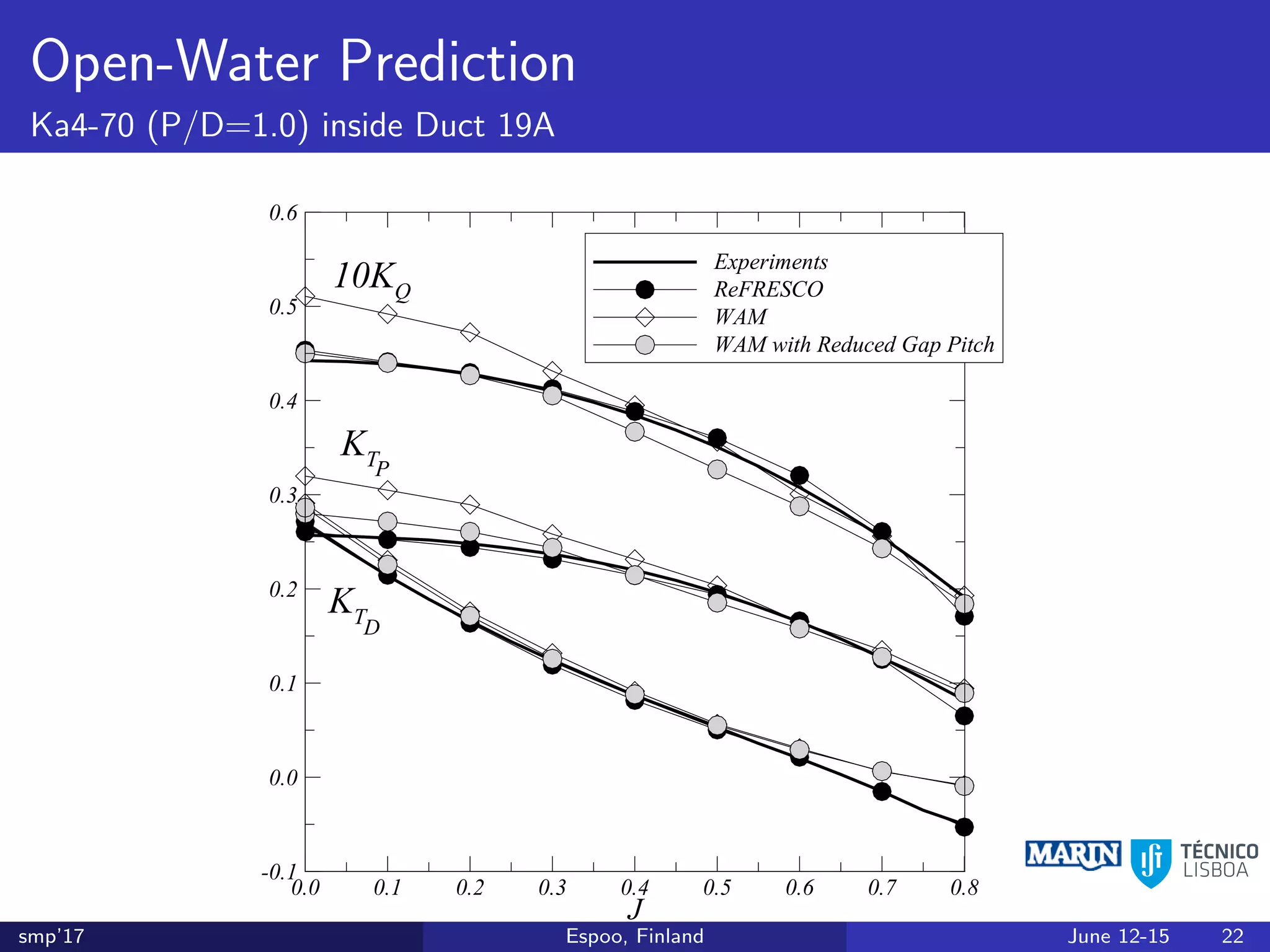

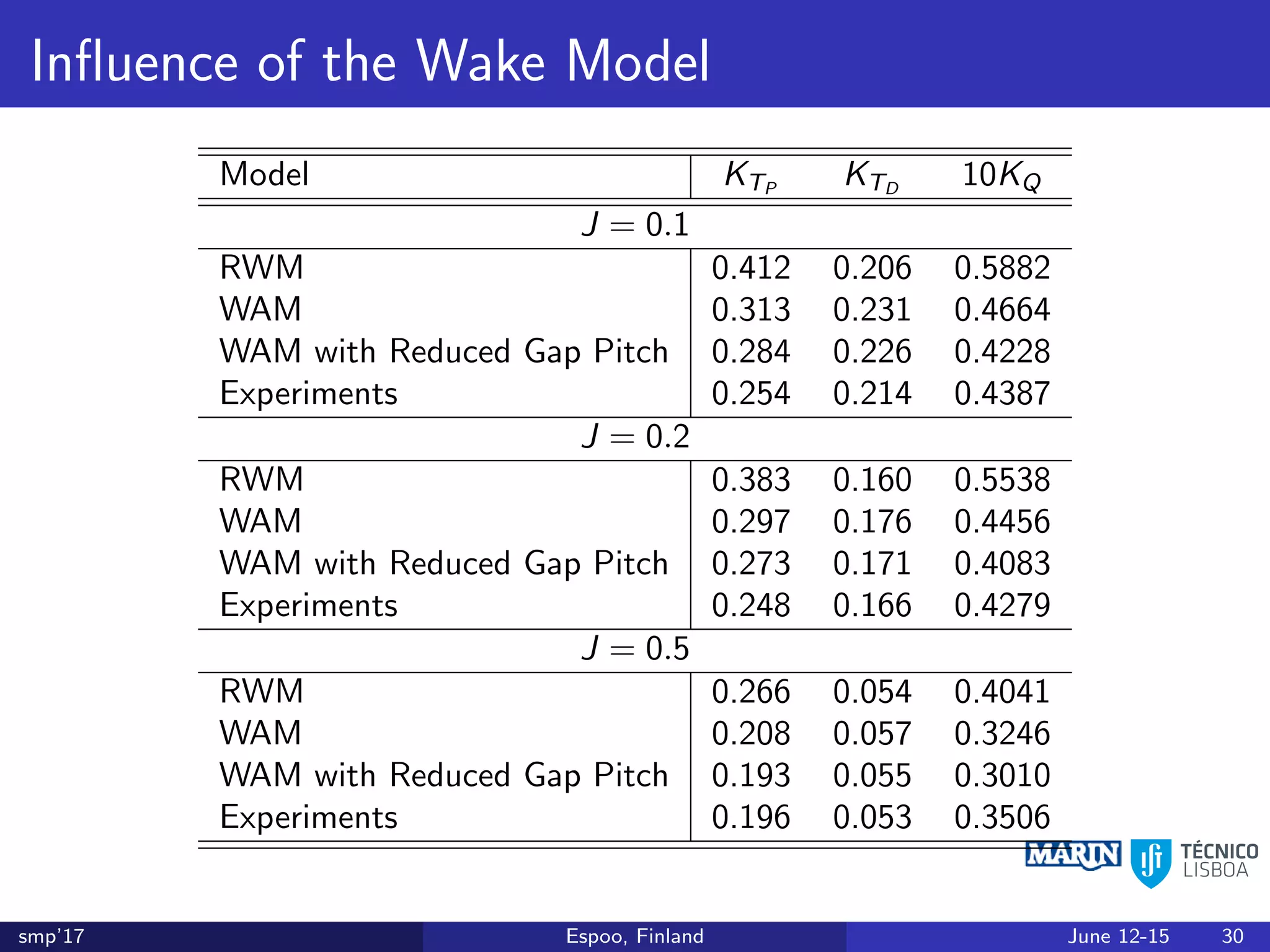

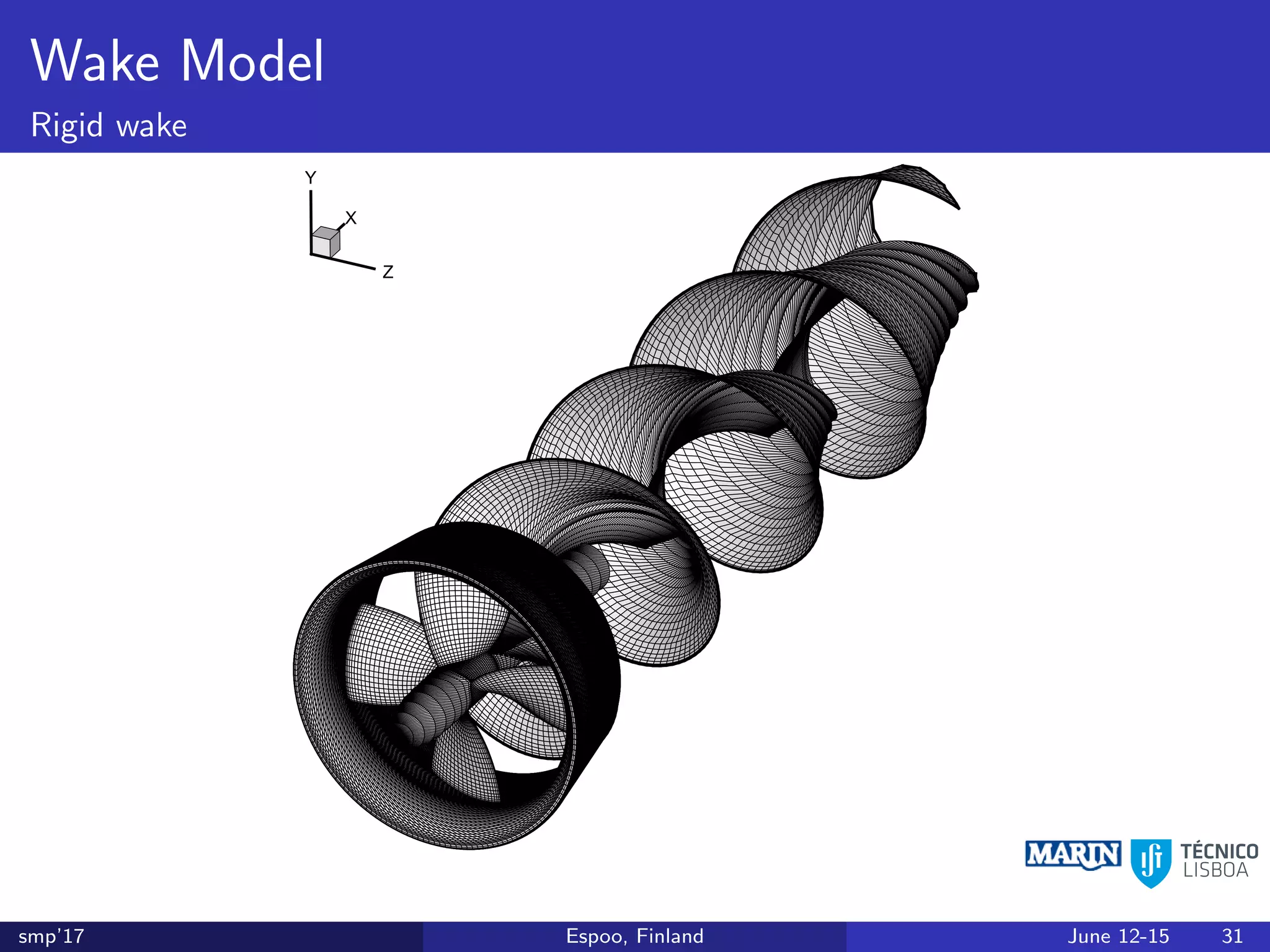

This document discusses the prediction of open-water performance for ducted propellers using a panel method. Panel methods provide a computationally efficient tool for analysis and design of marine propulsors. Application to ducted propellers involves additional modeling issues such as the complex interaction between propeller blades and duct surfaces. The document reviews previous work developing the panel method for ducted propellers, including models for the gap flow, wake alignment, duct boundary layers, and new Kutta conditions. It presents comparisons of panel method predictions to experimental and RANS results. The motivation is to improve performance predictions near bollard pull conditions through refinements to the numerical methods.