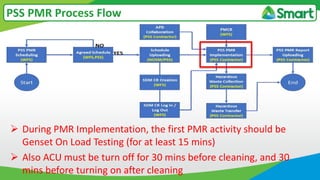

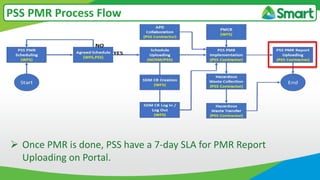

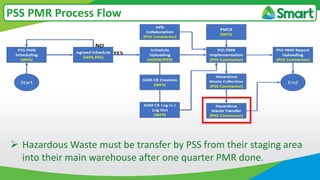

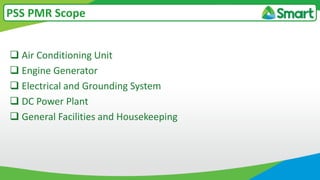

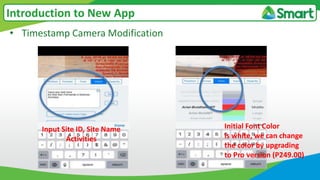

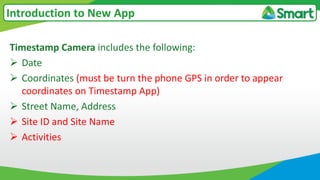

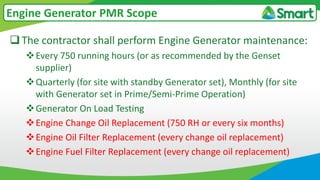

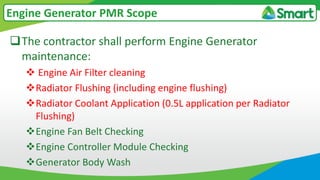

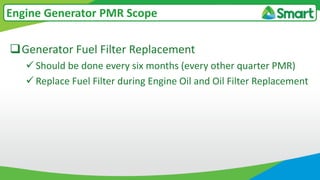

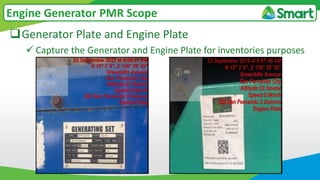

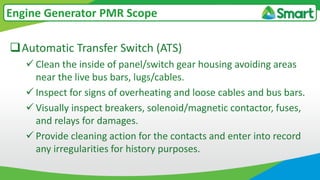

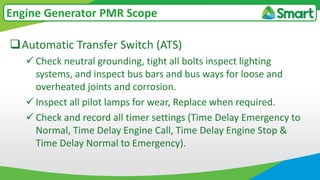

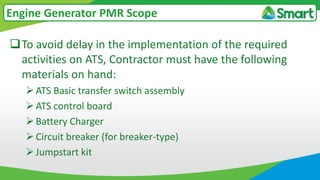

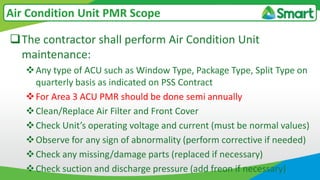

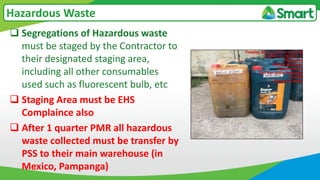

The document provides guidelines for preventive maintenance and repair (PMR) of equipment in Area 3, including introducing a new timestamp camera app, outlining the PMR process flow, and detailing the scope of work for engine generators, air conditioning units, and other electrical and mechanical systems. Key activities include testing generators, changing engine oil and filters, cleaning radiators, checking batteries, and cleaning air conditioning units on a quarterly or semi-annual basis. Contractors are responsible for properly disposing of hazardous waste and keeping adequate replacement parts on hand.