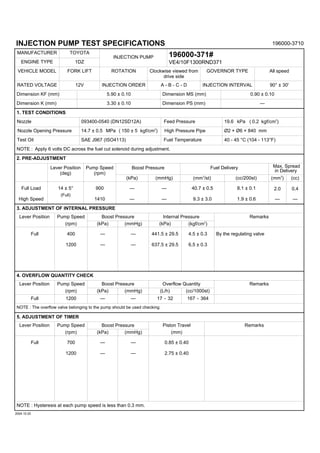

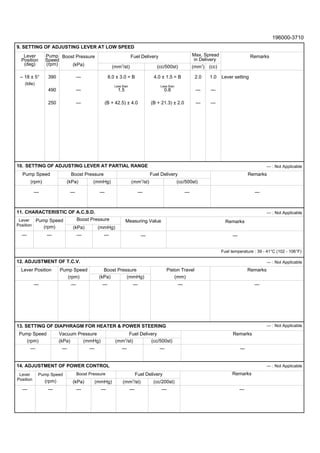

1. This document provides injection pump test specifications for a Toyota 1DZ engine in a 196000-3710 forklift.

2. It outlines 14 sections for testing and adjusting aspects of the injection pump like fuel delivery amounts, internal pressures, timer settings, and response to boost pressure and throttle position.

3. Tables provide target measurements for pump speed, fuel delivery, pressures, voltages and other values to confirm the pump is properly adjusted at idle and higher lever positions across its operating range.