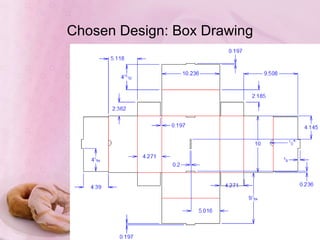

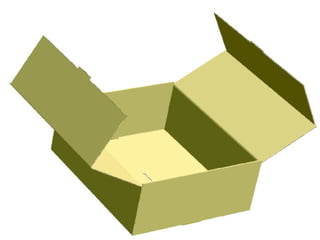

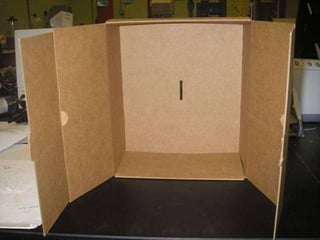

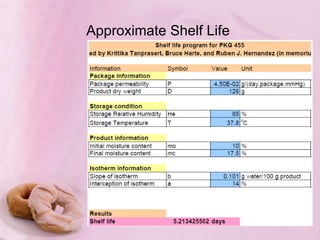

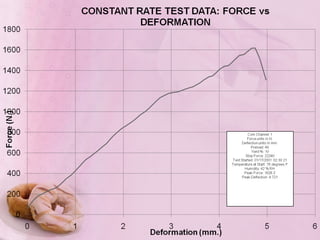

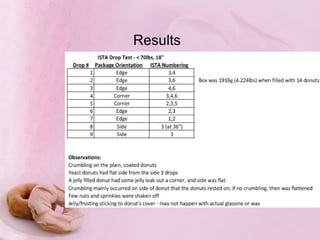

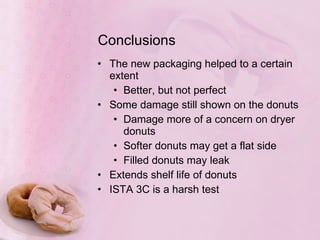

The Sweetwater Donut Project's packaging design focuses on a partitioned e-flute box that requires only tape for sealing, offering extra strength and moisture barriers for individual donuts. Sensory evaluations indicate varying shelf lives for different types of donuts, with filled donuts lasting longer than cake donuts. While the new packaging improved durability, some damage still occurred, particularly to dryer donuts.