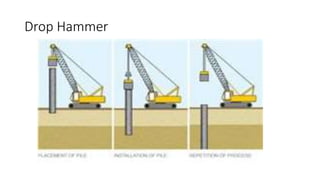

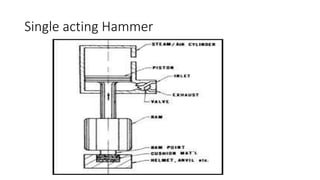

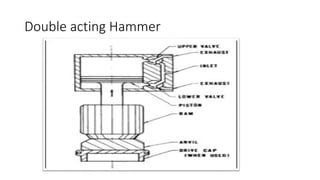

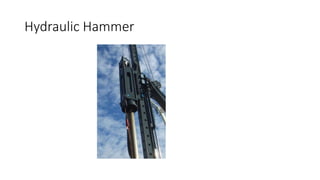

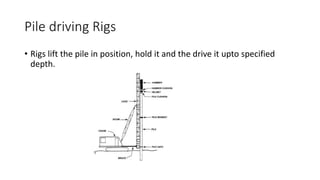

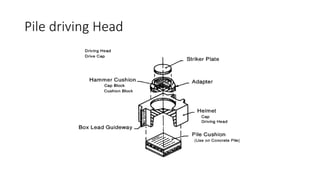

There are several types of pile driving hammers that are selected based on factors like the pile size and soil type, including drop hammers, single acting hammers, double acting hammers, differential acting hammers, diesel hammers, and hydraulic hammers. Pile driving rigs are used to lift, hold, and drive piles into the ground, and come in land drivers and floating drivers. Accessories for pile driving include pile driving heads, anvil blocks, cushion blocks, followers, spuds, and pre-excavators.