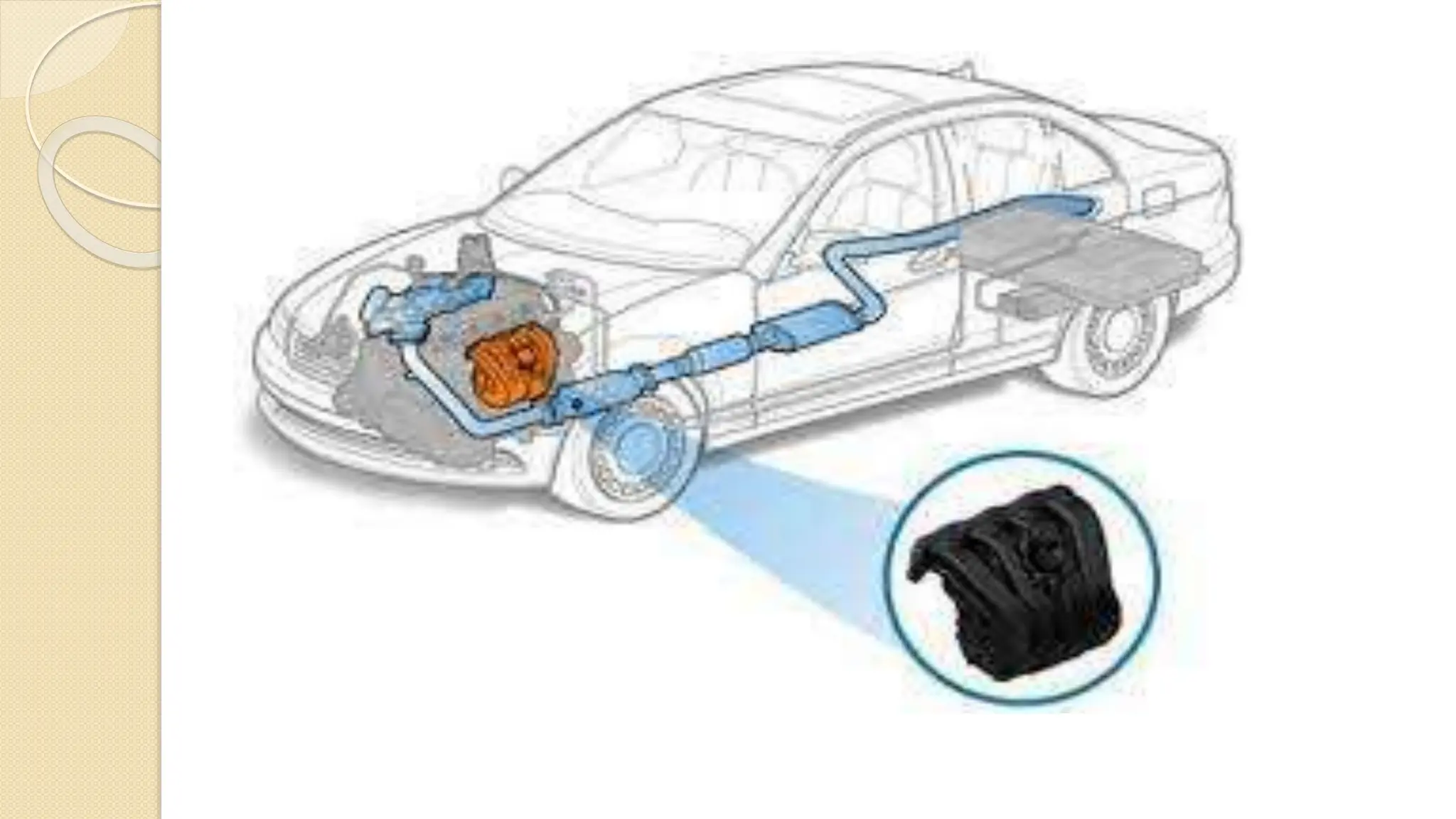

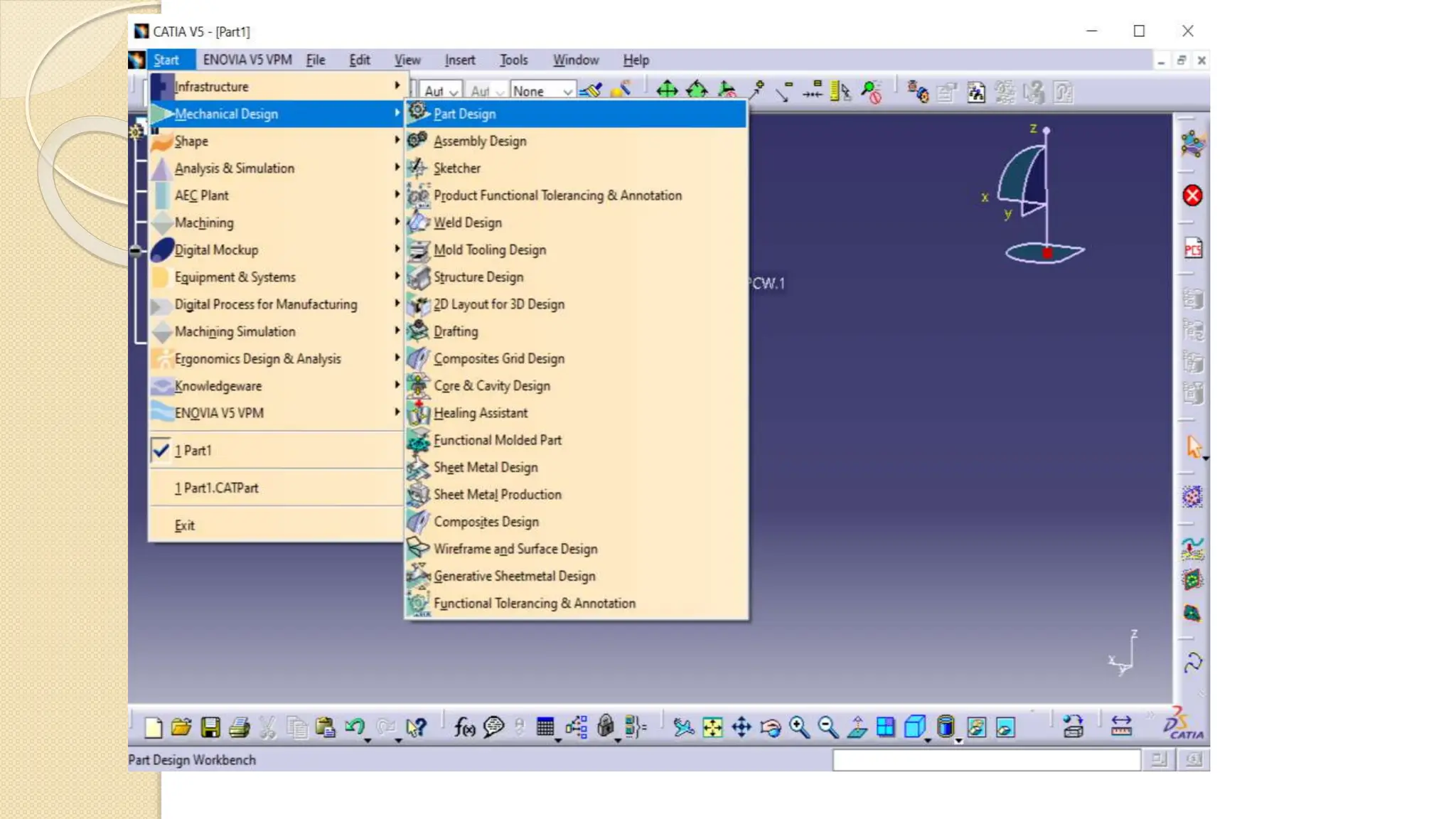

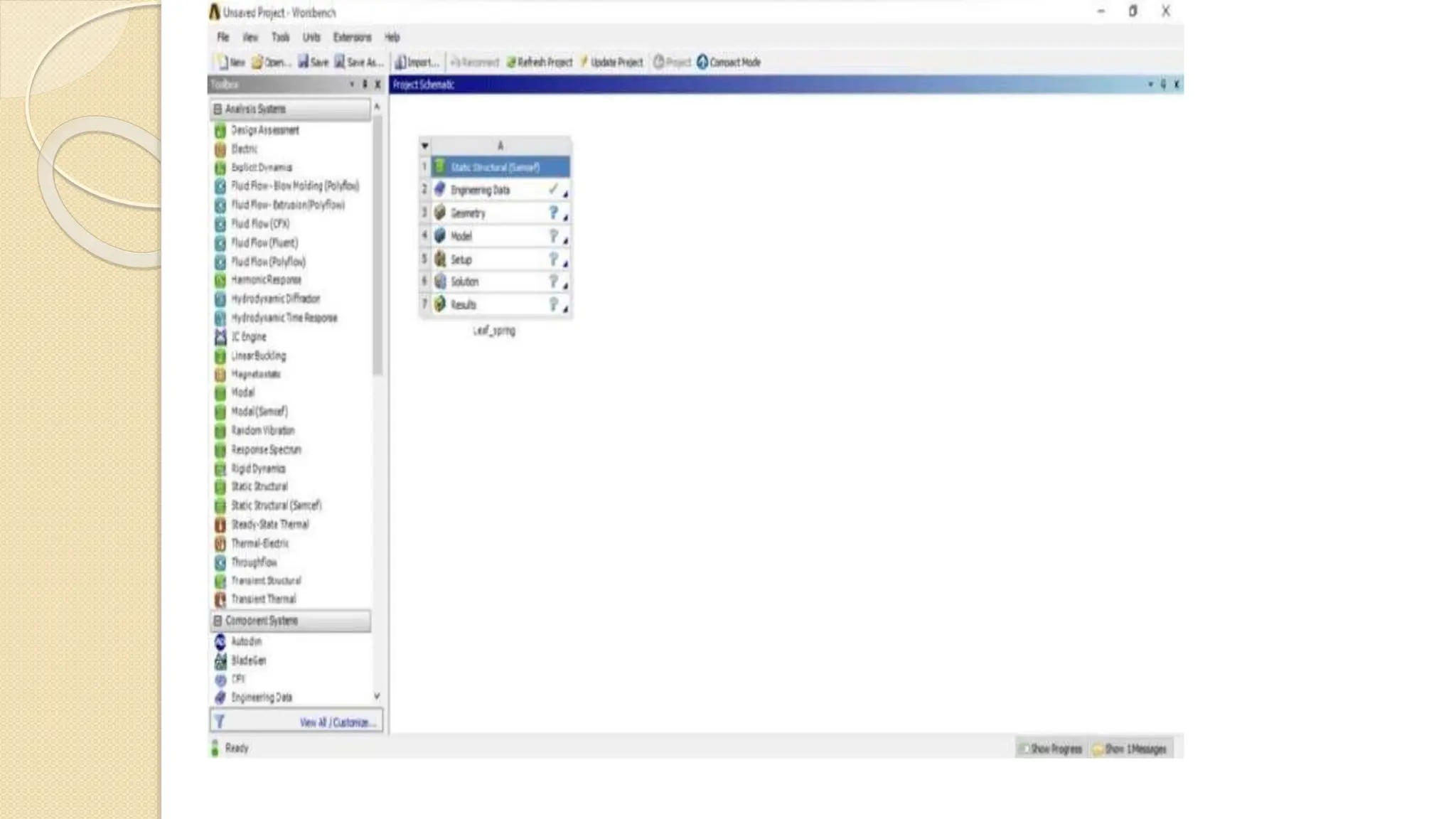

The document discusses the design and analysis of an intake manifold for an internal combustion engine using various materials. It aims to optimize the intake manifold design to maximize volumetric efficiency and even air distribution across cylinders. The methodology involves analytical calculations for different materials, CAD modeling, CAE analysis for stresses and vibrations, CFD analysis of air flow, and optimization of the design. The goal is to develop an efficient intake manifold model by varying materials and analyzing fluid flow characteristics numerically and comparing to experimental results.

![REFERENCES

1) Shrinath Potul, Rohan Nachnolkar, Sagar Bhave, “Analysis of Change in

Intake Manifold Length and Development of Variable Intake System”.

‘INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY

RESEARCH’ VOLUME 3, ISSUE 5, MAY 2014 ISSN 2277-8616

2) M. A. A. H. Pahmi, Sharzali Che Mat, A. N. Nasruddin,Mohd Fauzi Ismail,

Mohd Najib Yusof, “The Analysis of Intake Manifold Air Stream Velocity on

Different Material Roughness” ISSN: 1662-7482, Vol. 661, pp 143-

147[2014-06-20]

3) A. Jason D’Mello, B. Omkar S. Siras, “Performance Analysis for 4-

Cylinder Intake Manifold”, ‘An Experimental and Numerical Approach.

International Engineering Research Journal’ Page No 917-922 [2014]

4) Arvindkumar Ka ; Adhithiyan Nb ;Darsak V Sc; Dinesh Cd “Optimisation

of Intake Manifold Design Using Fibre Reinforced Plastic”, ‘International

Journal of Scientific & Engineering Research’, Volume 5, Issue 4, April-2014

ISSN 2229-5518, 922](https://image.slidesharecdn.com/phase1designandanalysisofintakemanifoldoficenginewithvariousmaterials-240112071931-96aa8bba/75/phase-1-Design-and-analysis-of-intake-manifold-of-ic-engine-with-various-materials-pptx-23-2048.jpg)