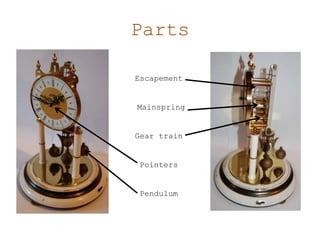

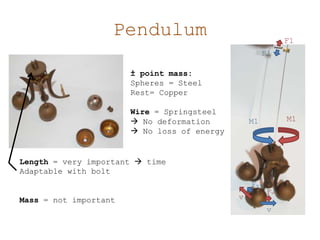

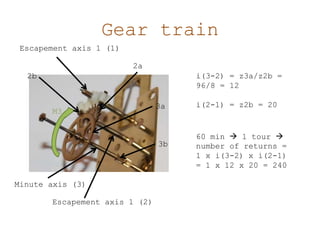

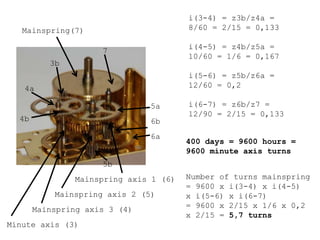

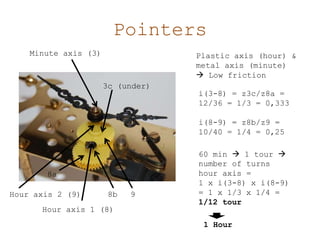

This document describes the parts and history of a pendulum clock. It was invented in 1656 by Christiaan Huygens, a Dutch inventor. The key parts are the escapement, gear train, pendulum, mainspring, and pointers. The pendulum regulates the time and its length and mass are important factors. The gear train uses different ratios to connect the mainspring to the hour and minute hands.